How meta-optics is enabling mobile-scale hyperspectral imaging

While conventional RGB cameras capture only three broad spectral bands, hyperspectral imaging captures the full spectral signature of materials and has long held promise across various industries. But legacy systems—dependent on bulky, mechanical, and costly dispersive optics—have kept this technology out of reach for mainstream applications. Traditional systems require prisms, gratings, or tunable filters with significant optical paths and precise alignment, which results in large, fragile, and expensive equipment.

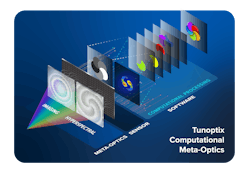

At Tunoptix, we’ve taken a fundamentally different approach and replaced mechanical complexity with an end-to-end meta-optical design that encodes spectral information directly at the point of capture (see Fig. 1). This eliminates the need for bulky dispersive optics or external processing and dramatically reduces the size and cost of hyperspectral systems. It opens new markets and applications.

Meta-optical architecture and design principles

At the heart of our platform is a codesigned system that combines meta-optical elements—engineered nanostructures fabricated with semiconductor lithography process—with proprietary machine learning algorithms. These metalenses and filters perform multiple optical functions simultaneously and are compatible with chipscale integration.

The result is a modular, multi-aperture architecture that supports high-fidelity hyperspectral imaging with these innovations:

Engineered metalenses. Our ultrathin metalenses are designed to preserve spatial detail while supporting high light throughput, which improves signal-to-noise compared to conventional systems. This enables high-resolution imaging within compact, mobile-scale modules.

Integrated spectral filtering. Codesigned meta-optical filters provide spectral discrimination across the full field to enable multiplexed spectral imaging per aperture and eliminate the need for bulky dispersive elements.

Spectral decoding. Our modules are calibrated to deliver spectral channel data directly, which eliminates the need for post-capture reconstruction. Optional software tools may fine-tune spectral alignment or support application-specific analysis.

This end-to-end meta-optics model consolidates spectral filtering and lensing into a compact hardware platform, enabling scalable and efficient integration without added system complexity.

Our current hyperspectral design achieves sub-20 nm resolution from 400 to 950 nm (VNIR) and fits within a 1 cm3 volume, which is over 1,000x smaller than traditional systems.

Hyperspectral module specs

- Imaging mode: Snapshot

- Spectral range: 400 to 950 nm (VNIR)

- Spectral resolution: <20 nm

- Per-channel resolution: ~720 x 480 pixels across 30+ channels

- Field of view: >60° diagonal

- Frame rate: 30+ fps

- Power consumption: <500 mW

- Operating temperature: -20°C to 70°C

Manufacturing and scalability

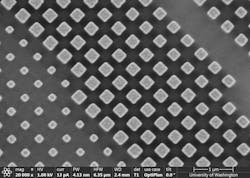

A critical aspect of our development strategy is to ensure scalable, high-yield manufacturing. Our meta-optical elements are manufactured using complementary metal-oxide semiconductor (CMOS)-compatible lithography processes, which enables wafer-scale fabrication through a fabless foundry business model (see Fig. 2). This ensures scalability, consistent quality, and lower cost per unit.

Post-processing includes automated wafer-level testing and CMOS image sensor integration, with process control to ensure consistent optical and spectral performance.

Real-world applications

By dramatically shrinking the form factor and cost of hyperspectral, our technology opens up new use cases:

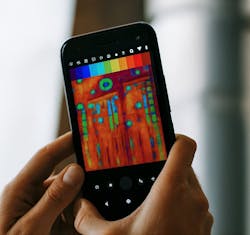

Mobile and consumer devices. Smartphones, wearables, and tablets can now integrate compact hyperspectral modules for food inspection, skincare, personal health monitoring, and enhanced color accuracy (see Fig. 3).

Healthcare and wellness. Our miniaturized modules support applications in skincare, oral care, and cardiopulmonary monitoring, including reflectance-based sensing of blood oxygenation and hydration levels.

Industrial automation and robotics. On the factory floor, our systems provide material classification and quality control within tight spaces. In robotics and AR/VR, they enhance machine vision and environmental assessment.

Agriculture and food safety. Field-deployable cameras assess crop health, ripeness, and contamination in real time to support precision farming and streamlined food inspection.

Defense and security. Tunoptix modules support lightweight, rugged-edge systems for situational awareness, hazardous material detection, and unmanned platforms.

Overcoming technical barriers

Creating production-ready meta-optical imaging systems requires addressing several fundamental challenges:

Calibration and stability. Automated procedures using tunable light sources and integrating spheres to map each pixel’s spectral response—it ensures spectral fidelity and channel-level accuracy in real-world lighting.

Environmental robustness. Designed to withstand temperature swings and humidity to maintain consistent optical behavior.

Computational efficiency. Optimized system response to support real-time spectral output on mobile and edge processors.

Integration support. Software development kits, reference designs, and calibration utilities to simplify OEM integration.

Strategic partnerships and technical ecosystem

Advancing meta-optical spectral imaging demands multidisciplinary expertise spanning optics, nanofabrication, computational imaging, and systems integration. Tunoptix partners with academic institutions, original equipment manufacturers (OEMs), and fabrication specialists to accelerate innovation and scale production.

Academic foundation and scientific roots

Tunoptix was founded at the University of Washington and maintains close ties to its academic origins. Cofounder Professor Arka Majumdar, an expert in meta-optics and integrated photonics, serves as a technical advisor. Our ongoing collaborations support foundational research in meta-optical design, advanced nanofabrication, and computational imaging. Tunoptix contributes to joint publications and university-led research programs.

Inhouse innovation and fabless execution

Core optical design and system engineering are led inhouse by Alan Zhan. Operating a fabless model, we partner with leading nanofabrication foundries and optomechanical integrators for packaging and assembly. This distributed approach enables rapid prototyping and supports scalable wafer-level manufacturing.

OEM and industry partnerships

Through a structured OEM engagement program, we provide partners with early access to our technology roadmap and support the development of custom modules. These engagements often include prototype creation, nonrecurring engineering (NRE) projects, and application-specific optimizations, covering custom meta-optic designs, spectral band targeting, and seamless integration into commercial platforms.

Roadmap and future focus

We’re building on our current platform to broaden capabilities:

Expanded spectral coverage. Expanding into the shortwave-infrared (SWIR) up to ~2500 nm for deeper material sensing—valuable in biomedical diagnostics, plastics recycling, and agriculture.

Higher resolution. Next-gen modules aim for 4K+ spatial resolution to support applications that require fine detail and spectral accuracy.

Application-specific designs. We tailor configurations for personal health and wellness-focused wearables, rugged industrial sensors, and embedded vision in drones and robotics.

Cost efficiency. Our goal is to deliver sub-$50 modules at scale to support mass adoption by consumer electronics and edge AI systems.

Spectroscopy modules. Beyond imaging, we’re exploring meta-optical modules for reflectance, absorption, and compact Raman spectroscopy to enable chemical and molecular sensing within portable formats.

Looking forward

Meta-optical spectral imaging represents a fundamental leap forward, transforming hyperspectral imaging from bulky lab systems into scalable, real-world solutions. Tunoptix delivers breakthrough performance in a radically smaller footprint, enabling the integration of spectral intelligence into everyday devices.

We invite OEMs, developers, and research organizations to explore partnership opportunities with us. Tunoptix provides reference designs, SDKs, and whitepapers to approved partners under a nondisclosure agreement (NDA). Contact us to learn how our technology can enhance your next-generation products.

About the Author

Alan Zhan

Alan Zhan, Ph.D., is the chief technologist for Tunoptix (Seattle, WA).

Naren Yellai

Naren Yellai is CEO of Tunoptix (Seattle, WA).