Thin-disk-laser power scaling improves welding efficiency

In recent years the high-power-laser community has seen dramatic changes. The introduction of increasingly reliable high-power diode lasers has enabled novel solid-state laser geometries with average output powers in the multikilowatt range. One of these technologies is the thin-disk-laser geometry, in which a highly doped (in excess of 10% ytterbium content) thin disk of Yb:YAG is pumped with high-power diode-laser stacks. The Yb:YAG disk is less then 0.2 mm thick and has a diameter between 10 and 20 mm, depending on the desired power level.

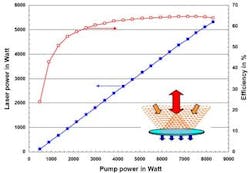

The thin disk is pumped from the front, with the pump light incident under a slight angle in order not to obstruct the main Yb:YAG laser beam. Light from the high-power diode-laser stacks is homogenized by a long glass rod (homogenizator) and collimated onto a parabolic mirror. The pump light is focused onto the thin disk and partly absorbed. The back side of the disk is highly reflective to the pump and the output beam light so the pump light exits the disk and is reflected by the parabolic mirror again. A prism pair displaces the pump-light beam azimuthally with respect to the central axis of the parabolic mirror and after being reflected by the parabolic mirror again, the pump light is focused a second time onto the thin disk. With three prism pairs this process can be repeated eight times, so that the pump light passes through the laser medium 16 times and is fully absorbed. The process is highly efficient--up to 63% of the diode-laser pump power is converted into output power of the thin-disk laser (see Fig. 1).

Thin-disk power scaling

An additional method of scaling disk-laser power without increasing the pump laser intensity is the sequential arrangement of multiple thin-disk media in the path of a single optical resonator. In a thin-disk laser with four thin-disk-laser media arranged in series, the main laser beam passes through the four media in a double-W configuration and allows the extraction of power from all media. Such a system can achieve an output power of nearly 10,000 W with four disks, even with the individual disks running at power levels far below record results. These industrial-caliber lasers have a guaranteed output power of 8 kW behind the optical-fiber delivery system. This delivery system consists of an integrated beam switch for up to six different outputs, beam-delivery fiber cable, and process optics.

Each component of the laser system contributes to the reliability of the application and it is important that uptime calculations include all components of the optical beam path from the laser to the focusing optics. Thin-disk lasers have proven this level of industrial reliability in many multikilowatt applications and are integrated into many production lines.

Welding applications

One particularly successful implementation has been for remote welding at Volkswagen. A scan head with two mirrors is held by a robot approximately 50 cm above the part to be welded. While the robot is coarsely following the path—which includes the welding joints—the scan head accurately positions the beam to weld the part "on the fly." The Volkswagen production technology department set up a pilot project in April 2005 and initial experiments confirmed successful welding, cutting, and soldering functions because of the beam properties of Trumpf's 4 kW thin-disk laser (see Fig. 2).The Volkswagen pilot series project used a Kuka KR 30 HA robot on which PFO 33 scanner optics (also made by Trumpf) were flange-mounted with a focal length of 450 mm. The Volkswagen Passat's rear shelf was produced on a rotary table centrally divided with two welding nests. With this arrangement the device could be loaded outside of the laser cell while welding was performed at the same time within the cell. The laser and optics components of the laser scanner process were given approval for serial production at Volkswagen in December 2005.

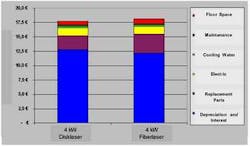

In a detailed examination of the economic viability of the process, the operating costs of the diode-pumped thin-disk laser were significantly reduced in comparison to the previously used lamp-pumped lasers. In addition, a comparison of the operating costs for current laser beam sources was conducted (see Fig. 3).The higher efficiency of the process is likewise reflected in the increased production speed. Since the process time can be reduced by a factor of three compared to conventional welding, the system only needs to be operated for two shifts to obtain the necessary daily yield. An availability rate of more than 99% was achieved during the pilot-series project for the production components including disk lasers.

Based on the experiences with the pilot installation, new-vehicle projects can now be planned with this production technology. Primary application potential currently falls in the area of doors, mounted parts, and welding-intensive subassemblies. Additional cost and efficiency potential could be realized by refining the thin-disk-laser concept.

About the Author

Holger Schlüter

Head of Business Development, SCANLAB GmbH

Dr. Holger Schlüter is Head of Business Development at SCANLAB GmbH (Puchheim, Germany).