Optical Surfaces debris shields for target-facing optics

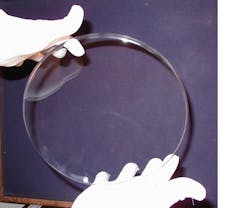

Debris shields to protect target-facing optics located in high-power laser facilities use a range of glasses, including BK-7 and fused silica, which offer homogeneity and transmission from the UV to the near-IR. Using proprietary techniques, debris shields are manufactured up to 600 mm in diameter, with typical wavefront error of λ/10 and surface finish of 40/20–10/5.

Optical Surfaces

Surrey, England

[email protected]

More Products

-----

PRESS RELEASE

Debris Shields Offer Protection of High Power Laser Optics

Debris Shields from Optical Surfaces Ltd. are specifically designed to protect target-facing optics located in high-power laser facilities. The use of debris shields to protect typically expensive final reflective or refractive focusing high power optics is a well-established technique of extending their lifetime.

Manufacturing high quality debris shields combines the dual demands of producing a precision wavefront on a flexible window with a high diameter to thickness ratio. Working with a range of glasses including BK-7 and fused silica, which offer good homogeneity and transmission from the UV to the Near-IR, Optical Surfaces Ltd. is able to supply customer specified debris shields of virtually any shape and thickness.

Benefiting from a stable manufacturing environment and proprietary production techniques Optical Surfaces Ltd.'s skilled and experienced craftsmen are able to economically produce debris shields up to 600mm in diameter with typical wavefront error of lambda/10 and surface finish of 40/20-10/5.

Optical Surfaces Ltd (www.optisurf.com) has been producing optical components and systems for more than 45 years and is now accepted as one of the world's leading manufacturers of high-precision optical systems for high power laser research facilities. The company's ISO 9001-2008 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent. With such stable conditions testing, particularly with long path lengths, becomes quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service.

For further information relating to high power laser optics and debris shields please contact Optical Surfaces Ltd. on +44-208-668-6126 or email [email protected].