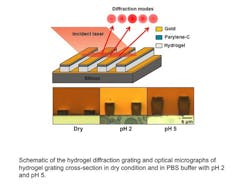

West Lafayette, IN--Researchers are developing a new type of biological and chemical sensor; the optical-diffraction-grating-based devices are made of stripes of a gelatinous hydrogel, which expands and contracts depending on the acidity of its environment.

Findings have demonstrated that the sensor can be used to precisely determine pH, revealing information about substances in liquid environments, said Cagri Savran of the Birck Nanotechnology Center at Purdue University. The grating stripes expand and contract depending on the pH level of the environment. "Many sensors being developed today are brilliantly designed but are too expensive to produce, require highly skilled operators and are not robust enough to be practical," said Savran. The sensors get their information from analysis of laser light reflecting off the gold-coated gratings. The diffraction pattern depends on the height of the stripes.

The pH of a liquid is recorded on a scale from 0 to 14, with 0 being the most acidic and 14 the most basic. Findings showed the device's high sensitivity enables it to resolve changes smaller than 0.001 on the pH scale, measuring a swelling of only a few nanometers.

The technology might be used in chemical and biological applications including environmental monitoring in waterways and glucose monitoring in blood.

"As with any novel platform, more development is needed, but the detection principle behind this technology is so simple that it wouldn't be difficult to commercialize," said Savran.

Findings are detailed in a paper presented during the IEEE Sensors 2010 Conference in November and also published in the conference proceedings.

Subscribe now to Laser Focus World magazine; it’s free!

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.