CRAIC Technologies automated system determines refractive index of glass trace evidence

The rIQ automated system combines image analysis software, advanced optical design and electronics—using the thermal immersion method, as defined by the standard ASTM E1967-98—to measure the refractive index of microscopic glass fragments. The system is available as a standalone package, as an add-on package to the company's microspectrophotometers, and as an upgrade package for older units already in the field. The standalone package consists of a phase contrast microscope, a high-resolution digital camera, optical interface, thermal stage, controlling electronics, and software.

CRAIC Technologies, in partnership with Laboratory Imaging

San Dimas, CA

http://microspectra.com/products/riq

More Products

-----

PRESS RELEASE

rIQ™-the Smart Way to Determine the Refractive Index of Glass Trace Evidence

rIQ™ is designed to determine the refractive index of glass quickly, accurately and easily. A vital instrument for any forensic laboratory, rIQ™ is offered in a standalone configuration, as part of a microspectrophotometer which includes color analysis of glass, or as an upgrade package.

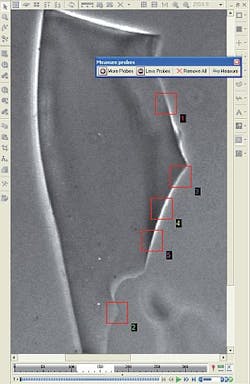

San Dimas, CA (February 21, 2011)-- CRAIC Technologies, Inc., the world’s leading innovator of UV-visible-NIR microscopy solutions, joins with Laboratory Imaging, s.r.o., a leading specialist in imaging software solutions for microscopy, to introduce rIQ™: the intelligent solution for the analysis of glass trace evidence. rIQ™, which stands for Refractive Index Quantification, is the result of a collaboration between CRAIC Technologies and Laboratory Imaging. rIQ™ combines sophisticated image analysis software, advanced optical design and electronics to enable criminalists in modern forensic laboratories to measure the refractive index of multiple glass fragments simultaneously, quickly and with the highest accuracy.

“The partnership between CRAIC Technologies and Laboratory Imaging is yielding great success. CRAIC Technologies expertise in optics combined with Laboratory Imaging's decades of experience with microscope imaging software is advancing the state-of-the-art in several fields. rIQ™ is the first result of this partnership and it promises to take the technique of forensic refractive index determination to the next level" states Dr. Paul Martin, President of CRAIC Technologies. “Glass fragments are common at crimes scenes. rIQ™ enables the forensic scientist to measure and compare the refractive index of the smallest fragments of glass with an incredibly high degree of accuracy. And when combined with CRAIC Technologies microscope spectrophotometers and microcolorimeters, the transmission and fluorescence spectral characteristics of glass evidence can also be determined quickly, accurately and all with the same instrument."

rIQ™ is an automated system that uses the thermal immersion method, as defined by the standard ASTM E1967-98, to measure the refractive index of microscopic glass fragments. The system, which incorporates many years of experience with the analysis of glass, allows the user to analyze the refractive index of multiple glass fragments simultaneously and with sophisticated analytical techniques. Statistical analysis methods can also be applied but the instrument is also designed to be user friendly with a short learning curve.

rIQ™ is offered as a standalone package, as an add-on package to CRAIC Technologies microspectrophotometers and as an upgrade package for older units already in the field. A standalone package consists of a phase contrast microscope, a high resolution digital camera, the optical interface, a thermal stage, the controlling electronics and the rIQ™ software. The add-on package can be integrated with many CRAIC Technologies microspectrophotometers models, both past and present, to allow them to measure the color, absorbance microspectra™, fluorescence microspectra™ and the refractive index of the smallest of glass fragments.

For more information about rIQ™ for the analysis of the refractive index of glass, visit http://microspectra.com/products/riq.

About CRAIC Technologies: CRAIC Technologies, Inc. is a global technology leader focused on innovations for microscopy and microspectroscopy in the ultraviolet, visible and near-infrared regions. CRAIC Technologies creates cutting-edge solutions, with the very best in customer support, by listening to our customers and implementing solutions that integrate operational excellence and technology expertise. CRAIC Technologies provides answers for customers in forensic sciences, biotechnology, semiconductor, geology, nanotechnology and materials science markets who demand quality, accuracy, precision, speed and the best in customer support.

Contact information:

CRAIC Technologies, Inc.

http://www.microspectra.com/

[email protected]

+1-310-573-8180