Berliner Glas expands coating capacity and expertise

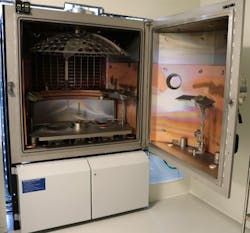

The Berliner Glas Group has expanded the coating center at its Berlin site with a customized advanced plasma source (APS) system, which facilitates the production of sophisticated coatings consisting of many individual layers (eg, edge filters, dielectric mirrors, or laser-resistant layers).

With a spectral range from the ultraviolet to the infrared, the new APS system increases the capacity for customer applications and the development of new technologies within the Berliner Glas Group.The optical monitoring system (OMS 5000) determines the optical thickness of the growing single layer during the coating process, compares it with the set values from the layer simulation in real time, and corrects any errors as needed. This OMS enables Berliner Glas to realize edge lengths with an accuracy of +/- 0.5 % at 650 nm. This opens the door to a wider market as this ensures compliance with increasingly stringent specifications.

With more than 1,100 employees, Berliner Glas develops, produces, and integrates optics, mechanics and electronics into innovative system solutions. It serves customers in market that include laser and space technology, semiconductor industry, medical technology, metrology, and the display industry.

Source:Berliner Glas Group