Researchers at the University of Strathclyde (Glasgow, Scotland) have used one of the commercial evaluation violet laser-diodes from Nichia Corp. (Anan, Japan) to perform confocal microscopy. Preliminary results indicate that the indium gallium nitride (InGaN) laser-diode may eventually provide a compact and efficient alternative to argon-ion lasers for some fluorescence-based imaging applications. "The diodes were purchased as part of a general investigation, but we knew that the first area we wished to look at was their potential application to confocal microscopy," said John Girkin, lead author of an article describing the research.1

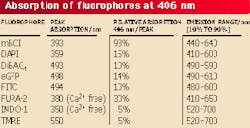

The laser diode used in the experiment currently has a wavelength range of 396 to 406 nm, which the researchers found of interest for some biological applications in fluorescent microscopy, such as calcium-ion indicators and stains for gluthathione, and for fluorophores currently excited at 488 and 351 nm that have absorption wings around 400 nm. These fluorophores include green fluorescent protein (eGFP) and its variations (see table). Prior to biological imaging, the researchers compared the laser-diode source with a 488-nm argon-laser source.

In the optical comparison, the 5-mW laser diode ultimately delivered 2 mW after passing through optics originally optimized for 810 nm, an air lens, and beam shaping. The air-cooled ion laser originally supplied with the microscopy system delivered a maximum of 5 mW through an optical fiber. Measured axial resolution and inferred lateral resolution of the shaped laser-diode beam and argon-ion laser fiber beam were almost identical.

Beam shaping of the laser-diode output played an important role in optimizing resolution and contrast of biological images because it tended to correct the astigmatism of the laser-diode beam (26° divergence angle in one plane and 6° in the other) to better fill the objective lens, provide a tighter focus within the sample, and improve axial resolution.

"We actually did try sending the light down a fiber, but the overall efficiency was not high and this was a far more complex route than using the anamorphic shaping," Girkin said. "With some higher-power devices now available, the use of a fiber may be more sensible. But the system to couple into and out of a fiber will always be expensive, so

I personally do not believe this is the best-engineered solution in the long run. The small size of the device means the source could be mounted into the scan-head directly."

Advantages of shorter-wavelength laser-diode imaging include better ratiometric imaging as background signals decrease due to less acceptor excitation. Signal-to-noise ratios should also improve due to the phase-sensitive detection enabled by the relatively easy modulation of laser diodes (up to 1 GHz for InGaN). Potential applications of the laser-diode system include DNA sequencing instruments and Raman spectroscopy.

REFERENCE

- J. M. Girkin et al., Opt. Exp. 7 (10), 336 (Nov. 6, 2000).

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.