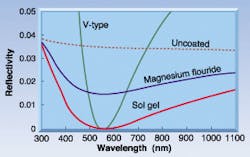

In a collaboration with the Smithsonian Astrophysical Observatory (Cambridge, MA), Cleveland Crystals (Highland Heights, OH) is now depositing sol-gel antireflective coatings on optics up to 0.8 m in diameter (top). A sol-gel thin-film coating consists of a single layer of material deposited from an alcohol-based solvent at ambient temperatures; such a coating combines the low reflection of a V-type coating with the broadband coverage of a single-layer magnesium fluoride (MgF2) coating, for example, on fused silica (bottom). Although sol-gel coatings are more fragile than traditional coatings, such fragility does not prevent them from being used at astronomical observatories, where a dry nitrogen dusting is often adequate for cleaning, and all optics come under a yearly inspection and possible refurbishment.

One important advantage of sol-gel coatings for large optics comes from the room-temperature deposition process, says Robert Dew, a senior project engineer at Cleveland Crystals. Ordinary thin-film coatings require that the optic go through a temperature cycle; the more massive the optic, the more likely a fracture will occur as a result of the large thermal mass of the piece to be coated. In addition, if the properties of the coating are not quite to specification, a sol-gel coating can be removed by rubbing it off with a cloth, whereas traditional coatings require the use of strong solvents followed up by polishing, potentially reducing the surface figure of the optics.

Cleveland Crystals has been coating sol gel onto small optics for years using a spin-coating process. It is the development of a workable dipping process that has allowed the company to graduate to large optics, according to Dew. "Many conditions have to be satisfied to make a pristine coating using the dip-coating process," he notes. Software was developed to take into account the effects of the curvature of the surface to be coated; in general, the drawing of the optic out of the sol-gel solution must be precisely controlled.

To date, the coatings have been used primarily for spectrographic instrumentation associated with large telescopes, such as the former Multiple Mirror Telescope at the Whipple Observatory (Mt. Hopkins, AZ), which was recently converted to a 6.5-m single-mirror telescope. Sol-gel-coated large optics are in the process of being incorporated into instrumentation at astronomical observatories around the world, says Dew.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.