eVCSEL light source provides deep colors

The use of lasers as light sources for rear-projection television (RPTV) has captured the attention of manufacturers in the drive to create true-to-life, movie-theater-quality imagery in the home. Microdisplay technology currently takes advantage of either the DLP (digital light processor) chip produced by Texas Instruments (Dallas, TX) or improved liquid-crystal-display panels to produce high-quality images over large screen sizes up to 70-in. diagonal. These displays are illuminated by conventional ultra-high-pressure (UHP) mercury-discharge lamps, which have limitations in brightness, color reproduction, and lifetime.

As an alternative light source for use with a DLP or other modulator, lasers have several compelling advantages. Their maximum linewidth of a few nanometers can increase the color gamut by 30% to 40% above the current color-reproduction standard (SMPTE C) using three primary-color sources. The need for color filters is eliminated, improving the power efficiency of the light-modulation system; associated UV and IR emission is also eliminated, operating lifetimes are significantly longer (exceeding 10,000 hours), and the directionality and small divergence angle of laser light cones allow for simple optical coupling.

These advantages, however, have yet to be made into a commercially viable light engine for RPTV, primarily as a result of the high manufacturing costs and packaging constraints of red, green, and blue lasers. A type of vertical-cavity surface-emitting laser (VCSEL) developed at Principia Lightworks, called the eVCSEL, is a low-cost laser intended for use in RPTVs (see Fig. 1). The laser can be packaged to fit within the footprint of today’s thinner RPTVs.

null

Electron-pumped semiconductor

The laser cavity of an eVCSEL comprises a gain layer of either a bulk single-crystal semiconductor, or a multiple-quantum-well (MQW) structure deposited by standard epitaxial-deposition techniques such as metal-organic chemical-vapor deposition. The gain layer, which varies from 5 to 10 µm thick and is about 2 cm2 in area, is sandwiched between a highly reflective mirror and an output coupler.

The material compositions of the gain layers for eVCSELs using MQW structures are, for red (640 nm), indium gallium phosphide/aluminum gallium indium phosphide (InGaP/AlGaInP); for green (540 nm), zinc cadmium selenide/zinc sulfide selenide (ZnCdSe/ZnSSe); and, for blue (460 nm), zinc sulfide selenide/zinc magnesium sulfide selenide (ZnSSe/ZnMgSSe). Semiconductors made from bulk materials use single-crystal wafers of CdSSe, CdS, and ZnSSe for red, green, and blue respectively. Because the eVCSEL has a divergence angle of approximately 30° and because the electron beam is scanning the laser medium, spatial coherence and therefore speckle is virtually eliminated at the source.

Carriers are injected into the cavity by a scanning-electron beam in a cathode-ray-tube (CRT) design. To minimize reflection losses and maximize the excited-cavity volume, the electron beam is deflected by 90° with a permanent magnet. The spot size is maintained at between 10 and 60 µm in diameter at an accelerating voltage of 35 kV and an electron-beam current of up to 2 mA.

As for the electron-beam spot, several factors are of consequence. For optimum eVCSEL performance, it is important that laser generation occur perpendicular to the layers in the structure, which limits the maximum spot size to approximately 60 µm in diameter. At the lower limit in an electron beam of less than 10 µm in diameter, diffraction losses begin to dominate, leading to an increase in laser threshold. In Principia’s eVCSEL, the electron-beam spot size is 25 µm in diameter, using magnetic focus with a prefocus electrode, allowing for a stable spot diameter for beam currents of up to 2 mA. Red-green-blue (RGB) eVCSELs are placed in a single CRT and scanned sequentially with one beam, or simultaneously in a three-beam system.

Optimizing dwell time

During scanning, each point is heated for brief lengths of time. The dwell time is determined by the electron-beam spot size and the scan velocity. The dwell time must exceed the carrier lifetime of 2 ns, but should not be so long as to quench laser generation by overheating. The optimum range for highest output power and maximum efficiency is a dwell time of 5 to 8 ns, corresponding to scan velocities between 5 × 105 cm/s and 3 × 105 cm/s for a 25-µm electron-beam spot diameter. For ZnSe, a current of 1 mA, and a spot velocity of 5 × 105 cm/s, the change in temperature, ∆T, is 38 K.

In actual operation, a temperature gradient occurs along the excitation-area diameter in which the average temperature is Tav + ∆T/2, where Tav is the background temperature of a given “pixel” before pulse excitation. For a current of 1 mA and a scanning area of 1 × 1.4 cm, it is necessary to remove about 20 W of heat.

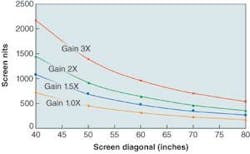

A 1000-lumen white-light eVCSEL source with emission wavelengths of 640, 530, and 460 nm balanced to 6500 K requires 2, 1.2, and 1.2 W of output power for each wavelength respectively, with a total input power of less than 120 W. Rear-projection TVs typically have an on-screen brightness of 350 nits for a 52-in. display with a 16:9 aspect ratio, and less for larger diagonals having a screen gain of 3× to 4× (screen gain is a characteristic of the screen itself; a higher screen gain comes at the expense of a smaller viewing angle). A 1000-lumen eVCSEL will put an excess of 500 nits on a screen having a diagonal screen size exceeding 70 in., while using a screen with a gain of only 2× (see Fig. 2). Brighter images, with larger viewing angles and manufacturing costs comparable to those for units based on UHP lamps, are the result.

Previous electron-beam-pumped lasers were pumped in a longitudinal mode, which requires a transparent epoxy as well as a transparent substrate-usually sapphire-to attach the laser. This has the disadvantage of poor heat conduction as well as a limit on the service life of the device resulting from thermal breakdown of the transparent epoxy. As a light source, the eVCSEL does not require optical transparency in either the bonding layer or the mounting substrate. Rather, a metal substrate is used with high thermal conductivity; adequate cooling is achieved by forced-air convection. Thus, lifetimes of 10,000 h are attainable, exceeding the operating lifetime of conventional UHP lamps.

The optical system for the eVCSEL light source accommodates the entire field of view of the light-spot scanning area; although the spot is moving, a stationary and uniform illumination field is produced on the DLP or other modulator (which is then imaged onto the projection screen). The RGB light sources can be fashioned in the form of a single three-color CRT, or with one CRT per color. Depending on the RPTV manufacturer’s preference, several optical arrangements can be used. For example, an “x” cube beam-combining assembly can be used with individual RGB light sources. With the addition of external optics, the light can be shaped to conform to the particular modulator being used.

Extended color gamut

Whenever an extended color gamut is used that is outside the industry-standard color spaces (of which SMPTE C, SMPTE 240M, and ITU-R BT.709 are a few examples), so-called “stretching” occurs, which produces errors in the color reproduction of the image. Appropriate lookup tables can be used to compensate for this stretching.

The extended color gamut also presents an interesting opportunity. Current color standards can be viewed as cropped in comparison with the color-sensing abilities of the human eye, as well as in comparison to the color content of many existing images. Many major motion pictures, for example, have used the dye-transfer process (“Technicolor”) for theatrical-release film prints; the vast amount of color information available in a color negative is greatly diminished in a standard-release print and is lost when displayed on home televisions.

The eVCSEL light engine has the potential to allow such true movie-quality images to be viewed in the home. For many who have seen presentations of an extended color gamut, the resulting beauty and richness of color results in an experience far superior to that of a conventional presentation.❑