An adaptive scanning optical microscope (ASOM) developed by researchers at Rensselaer Polytechnic Institute (RPI; Troy, NY) combines adaptive optics with a clever use of a curved image field; the result is an instrument that scans very large areas without having to move the specimen stage.1 An ASOM with a six-element objective lens can have up to a two-order-of-magnitude larger overall field size than a conventional microscope with a six-element objective.

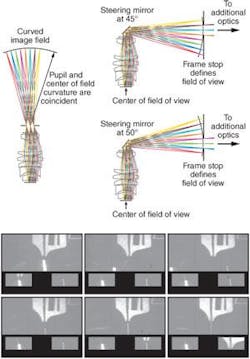

During design optimization of a large-field multielement lens, most designs naturally evolve toward having a curved image field. Rather than fighting this trend (a battle that can have only two outcomes: a small field size, or increased complexity and cost of the lens), the researchers went with the curved image field. They designed an objective lens with a spherical image field that has a radius equal to its distance from the scanning mirror; during scanning, the curved, magnified field rotates past an (intermediate) image aperture in the system like a wheel spinning in place on the road, always maintaining contact-or, in the case of the ASOM, best focus. The CCD image sensor, at the final image plane, is flat.

Taking the design load away from flattening the field, and also designing for monochromatic light, allowed the researchers to expand the field greatly while keeping the lens simple, but off-axis aberration remained a problem. This is where the adaptive-optical mirror cames in: as the mirror scans its small subfield through the overall field, the mirror constantly corrects aberrations for the subfield.

The ASOM is especially suited for uses in which smaller portions of a large field must be accessed rapidly; with only a fast two-axis galvanometer mirror moving instead of a stage, the lens takes on a “random-access” quality. The ASOM development at RPI was aided by a collaboration with a U.S. semiconductor-equipment company, says Benjamin Potsaid, the lead research specialist.

As a first test, the group built a prototype with off-the-shelf optics, no adaptive mirror, a numerical aperture (NA) of 0.05, and a field size of slightly less than 10 mm. The microscope has imaged a microgripper in action, as well as living cells in motion (see figure). The next version, which contains a deformable mirror from Boston Micromachines (Watertown, MA) with 100 electrostatic actuators, is under construction; also using off-the-shelf optics, it will cover a 20‑mm field and have an NA of 0.1.

Custom version

The group has also designed a fully customized version with a 40-mm-diameter field and NA of 0.21, used at a wavelength of 510 nm. Combined with an 8-megapixel sensor, the custom version will be able to scan its entire field in 0.27 s at a diffraction-limited resolution of 1.5 µm (and subfields far faster), predict the researchers. A white-light or broadband design would have a significantly smaller field of view, says Potsaid, although a more-symmetric lens design may better manage chromatic aberration.

“For a future version of the ASOM, we expect to be able to stitch the mosaic together in real time by using rapidly executing distortion-compensation algorithms combined with open-loop placement of the image tiles,” says Potsaid. “This would be useful for vision feedback and monitoring of the process in general, but the tiles may not match perfectly along the image seams. If a very high-quality image is required, the image tiles could be stitched together as a post-processing operation to generate seamless image mosaics from the stored image data.”

REFERENCE

1. B. Potsaid et al., Optics Express13(17) (Aug. 22, 2005).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.