One of the common images of 2000, as viewed from the 1960s, was the happy commuter who, after a smooth ride home on the monorail or helicopter settles down in front of the family's holographic, lifesize, full-color three-dimensional (3-D) television display. Unfortunately, this future vision is still just that, somewhere in the future. Nevertheless, while 3-D videos don't show up in living rooms, they are making an appearance in research laboratories. The vivid colors of two-dimensional (2-D) laser displays are further along, though, making these devices ready for some niche applications.

The problem facing researchers working to develop lasers for either 2- or 3-D entertainment displays is high cost. At the moment, laser displays face stiff competition from conventional techniques that are far less expensive, even though they may lack the quality of laser-produced images. Until the cost gap is closed, laser displays may remain future technology for most people.

Holographic-video progress

The idea of holographic-video, full-3-D color TV was first proposed in 1965, not long after the invention of the laser itself. The idea was far ahead of its time because holographic-video images require the transmission and processing of huge amounts of data, well beyond anything that could be handled even in the 1970s. It was not until 1990 that the first holographic-video system was developed in a laboratory at the Massachusetts Institute of Technology (Cambridge, MA). The system used an acousto-optic modulator to impose the holographic data on a laser beam and a rotating polygonal mirror to scan the image and break up the continuous-wave light into a series of video frames. The image was small—7 × 13.5 cm.

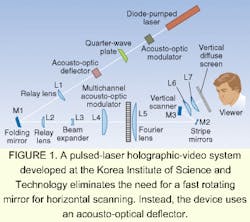

Progress since this pioneering step has continued at a modest pace until recently. This past year, Jung-Young Son, a researcher at the Korea Institute of Science and Technology (KIST; Seoul, Korea), developed a display approach based on pulsed-laser output that eliminated moving optical parts such as the horizontal scanning mirror.1 This technique forms a line hologram from every group of six pulses.

The experimental system at KIST uses only a single color—green—from an argon laser, but the approach could be expanded to full three-color (red-green-blue) operation. The laser is modulated by an acousto-optic modulator into a 50-kHz pulse train and then fed to an acousto-optic deflector made from tellurium oxide crystals. The deflector scans each pulse sequentially into one of six vertical positions corresponding to the facets of a fixed polygonal mirror (see Fig. 1). The vertical deflection is transformed optically into a horizontal line that is swept across a multichannel acousto-optic modulator that imposes the computer-generated holographic data on the beam. Finally, a vertical scanning mirror sweeps the line hologram to create a complete holographic image.The current system still produces a small image, a strong disadvantage compared to the main competing technology for 3-D video—multiview images. In this technique, slightly different images are projected in different directions, with the human brain generating a stereoscopic illusion. Such multiview images lack the true 3-D effect of holograms but are not limited in size. Neither approach generates vertical parallax—the ability to see different views by moving the head up or down. Because current holographic techniques generate only line holograms at any given instant, there is no vertical parallax, so the illusion remains imperfect. The TV-sized full-color holographic video still seems fairly distant.

Laser displays carve their niches

Laser display technology, although not yet competitive with cathode-ray tubes (CRTs) and arc-lamp projection systems, is far closer to commercialization in smaller markets where its advantages outweigh its higher costs. Laser displays are extremely bright, with high color saturation that gives them a brilliant appearance. In addition, the collimated laser beams essentially have an infinite depth of focus that makes them ideal for projection onto curved surfaces. Applications that would benefit include virtual reality or head-up displays on curved windshields.

Several companies are actively trying to get a foothold in this emerging market with their technologies aimed at direct-write laser displays. In these displays, the laser beam takes the place of the electron beam in a CRT and writes the image by rapidly scanning line by line over the whole display area. An example is a system from Laser Display Technologies (Gera, Germany) that achieves a horizontal scan by rotating a 32-facet polygonal mirror at 1000 revolutions per second. A second vertical scanning mirror then forms the image with 500 lines/frame. Red, blue, and green lasers are scanned in parallel into the same mirror system.

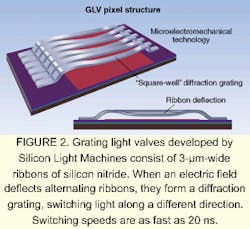

To reduce the need for high-speed mirrors, other companies have developed switching technologies that are both fast and able to withstand high power densities. For example, Silicon Light Machines (Sunnyvale, CA) developed a grating light valve (GLV) that uses a diffraction grating to switch laser beams into or out of the light train.2 Each GLV pixel consists of an even number of doubly supported ribbons of silicon nitride (see Fig. 2). The ribbons are typically 3 µm wide, 100 µm long, and 100 nm thick, which creates a pixel size approaching 25 x 100 µm. An air gap of about 650 nm separates the ribbons from the ground plate, and the whole structure is overlaid with an aluminum layer.With no voltage applied to the aluminum electrodes, the ribbons lie flat and act as a simple reflector. Apply a voltage to the electrodes over every other ribbon, and the ribbons deflect, creating a diffraction grating. Light impinging on the grating is then diffracted in a direction different from that when the light was reflected. Because of the small distance involved in the ribbon motions, switching times are extremely fast, in some cases taking only 20 ns.

A linear array of GLV pixels can modulate a laser beam focused to a line source, creating a single scan line of an image. Generation of the full 2-D projected image then requires only a relatively slow vertical scanning mirror.

All large-scale laser display technology suffers from the need for relatively powerful and, thus, expensive lasers. Power demands vary from about 1 W for a computer monitor to several watts for a TV, more than 20 W for a conference room projection display, and greater than 100 W for digital cinema. At the moment, this requirement limits the use of lasers in place of conventional displays for mainstream applications. Where cost is not the only criterion, though, the superior quality of laser images can make them desirable.

Writing an image on the retina

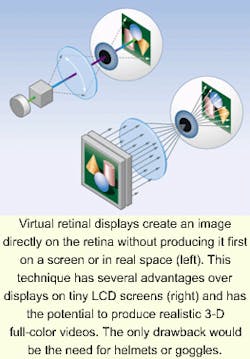

In one application, high laser power is not required. Microvision (Seattle, WA) has a virtual retinal display (VRD) that scans an image directly from tiny diode lasers onto a human retina without an intermediate screen.3 The device mounts in goggles or on a helmet and comprises nanowatt diode lasers (with far too little power to harm the eye), modulators, and a scanner (see photo at top of this page). The VRD uses point-scan technology, with only a single laser beam entering the eye at any instant. The device thus uses the retina in place of a CRT or similar display screen.

The scanner is a 1-mm-wide mirror mounted on a torsion arm that a magnetic motor causes to vibrate. Software corrects the timing of the laser modulation, imposed by an acousto-optic modulator, to correct for the slower speeds at each end of the scan.

The technology offers several advantages over the competing approach based on a miniature flat-panel display, such as a liquid-crystal display. Far less light is wasted, and the extra demands of miniaturizing a fine-resolution display are eliminated. In the VRD, each pixel is created virtually by the deflection of the beam, rather than in real space via a tiny array.

Current applications for the Microvision device are military and industrial in nature and only on a demonstration basis. The brightness of the display allows daylight use. The user also can view the real scene in front of him or her, as well as the virtual scene from the VRD.

So far, VRDs have not been used for entertainment, but that may not be far off. By projecting stereoscopic views to the viewer's eyes, the display has the potential to create 3-D full-color videos without the daunting technical difficulties of holography. This application will require three-color diodes, which may soon be available. Whether everyone can be persuaded to don the requisite goggles or helmets is another issue.

REFERENCES

- J.-Y. Son, Proc. SPIE 3733, 316 (June 1999).

- See www.siliconlight.com/frames/tech/frame_tech.htm

- See www.mvis.com

About the Author

Eric J. Lerner

Contributing Editor, Laser Focus World

Eric J. Lerner is a contributing editor for Laser Focus World.