Blue Semiconductor Lasers: Surface-emitting laser becomes blue-light source

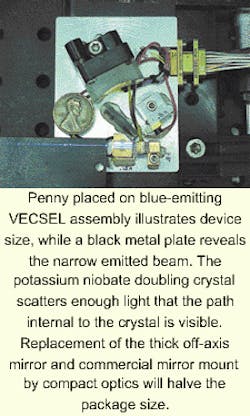

Researchers at Sandia National Laboratories (Albuquerque, NM) have developed a blue-emitting frequency-doubled light source that is built around a diode-pumped vertical external-cavity surface-emitting laser (VECSEL). Compact and rugged, the device is another entry in the race to produce a small, long-lived, and efficient blue emitter for such applications as high-density optical storage, full-color laser-projection displays, and sensing. The 490-nm-emitting laser produces a 9-mW beam that is not far from TEM00 in quality (see image on p. 22). The researchers have also constructed a 980-nm-emitting (non-frequency-doubled) version that reaches a 40% optical-to-optical efficiency with good beam quality.

At the heart of both devices is a semiconductor structure grown on a gallium arsenide (GaAs) wafer; the structure includes a distributed-Bragg-reflector (DBR) back-cavity mirror and a quantum-well gain region. The impinging beam of the pump laser defines the aperture of the gain area, which can range from 50 to more than 100 µm in diameter at the 1/e2 points. The blue emitter also incorporates a potassium niobate (KNbO3) nonlinear crystal into the cavity; the output end of the crystal is coated to reflect the fundamental wavelength and transmit the blue, thus becoming the cavity output mirror.

The 800-nm-emitting pump diode laser is a simple single-strip edge emitter, rather than a diode array. Light from the pump laser is imaged by a separate off-axis curved mirror onto the surface of the VECSEL at an oblique angle, spreading the pump laser's elliptical spot into a circular area having a Gaussian intensity profile. This is the best profile for producing a high-quality beam from the VECSEL, notes Joe Alford, a Sandia researcher. A half-wave plate rotates the pump laser's polarization by 90° for maximum coupling into the semiconductor structure.

For blue emission, the 7.5-mm-long KNbO3 crystal is placed 1-3 mm away from the upper surface of the GaAs wafer. The uncoated wafer surface and the DBR form an additional cavity that acts as a low-finesse intracavity etalon, narrowing the blue output spectrum to 0.5 nm wide. Adding a DBR to the wafer's upper surface can further narrow the spectrum by a factor of two, says Alford. The resulting beam has a divergence of approximately 10 mrad, with beam quality depending on how well the pump laser beam matches the lowest-order transverse mode of the VECSEL cavity. "When you do your homework right, you can get a very nice beam," says Alford.

The device produces blue-green light at an optical-to-optical conversion efficiency of 1.5%. The relatively low efficiency results from poor phase-matching in the KNbO3 crystal and will be improved by narrowing the doubled light spectrum and fine-tuning its central wavelength. The resulting 490-nm output is high on the photopic response curve of the human eye and is thus very bright, according to Alford. For color applications such as laser projection, however, the output wavelength is not ideal. Although shortening the output wavelength to a true-blue 450-470 nm can likely be accomplished by changing the composition of the VECSEL's quantum wells, lengthening the output into the green will be more difficult, says Alford.

If required, the emitter can be built into a small, battery-operated package. The largest pieces of hardware are the pump-laser focusing mirror and the off-the-shelf mirror mount it is fixed to. Replacing the mirror and mount by a diffractive optical element will reduce the package size by a factor of two, according to Alford. He notes that a laser pointer built by the Sandia researchers for demonstration purposes has proved to be robust. "It has made quite a few trips around the country," he says.

The researchers are working on directly electrically pumping both the blue and the high-power 980-nm-emitting devices, a step that would make them smaller, simpler, and easier to align. However, achieving uniform electrical pumping across such large apertures is not an easy task, Alford says. There is currently some commercial interest in the optically pumped emitters, but, according to Alford, the interested parties appear to be holding out for electrical injection.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.