There is no light source brighter than the laser; single-transverse-mode lasers can be considered point sources and thus have the smallest possible product of beam size and solid angle. One can play fast and loose with the term "entropy" and apply it to the laser, pronouncing it the light source with the highest order and thus the lowest entropy. However, it is not the randomly polarized laser that occupies this exalted state, but the linearly polarized laser (two linearly polarized beams can be combined into one and remain a point source). In practical terms, a linearly polarized laser beam is often of more use than a randomly polarized beam of the same power, because it can be redirected by polarizing optics with little loss.

For this reason, achieving polarized output in a type of laser that ordinarily produces randomly polarized light is good news. Researchers at the Université Jean Monnet (Saint-Etienne, France) and the Institute of General Physics (Moscow, Russia) have developed a Nd:YAG microchip laser containing a grating on one of its cavity mirrors that ensures a linearly polarized output. Although a linearly polarized microchip laser has previously been developed elsewhere, the effect was induced by a mechanical strain in the laser crystal—a method not easily adaptable to mass production.

Device manufacture

Made on a wafer and diced into chips, microchip lasers are intrinsically well suited for mass manufacture. Because the polarizing grating on the newly developed laser can be fabricated with the same planar techniques used to make the rest of the laser, the devices can be made quickly and in large quantities.

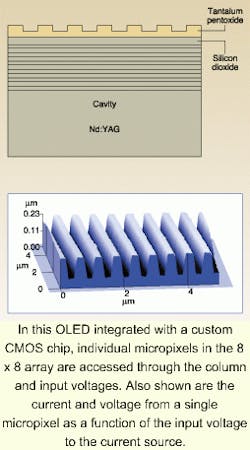

The principle relies on waveguide-grating interference, in which the reflection of one polarization off the grating can be set to between zero and 100%, depending on the grating parameters. The grating is formed on the outer surface of the multilayer mirror using electron-beam lithography (see figure). The last pair of low- and high-index layers is thicker than the others, having an optical thickness of Λ. The grating period is set such that the undesired polarization is coupled into a waveguide mode of the grating and then back into the cavity with a phase shift of pi, causing destructive interference for that polarization. For a multilayer coating of silicon dioxide and tantalum pentoxide, the grating period was set to 620 nm and the groove depth to 140 nm. The resulting reflection ratio for the two polarizations is approximately 0.32, enough to prevent the lasing of one polarization.

The ratio of the emitted polarizations is -17 dB, while scattering from the grating is much lower than 1%. Further development that includes thinning of the grating depth will reduce the scattering, the researchers say. Measurements show that the polarization-selecting effect of the grating is likely wide enough in bandwidth to polarize all the modes of a high-power multiple-longitudinal-mode microchip laser.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.