With the almost unstoppable thirst for smaller and lighter electronic equipment, the demand for multilayer print wiring boards (PWBs) is on the rise. To meet production requirements, many companies are exploring alternative manufacturing techniques. Drilling the tiny interconnection holes (vias) through the board by laser is one option, but there are some fundamental problems related to board material composition that must be overcome. Researchers at Matsushita Electric Industrial Co. (Kawasaki and Osaka, Japan) think the solution lies in a redesigned optical system that can convert a single-mode Gaussian beam into a beam profile with uniform irradiance.

A PWB consists of resin, glass fiber, and copper foil. A typical laser drilling system will irradiate a mask with the laser beam and project the image of the mask onto the PWB using scanning lenses. Most of the intensity distribution of the laser beam has a Gaussian beam profile, and the profile reaching the PWB has high intensity at the center and low intensity at the periphery. These characteristics can lead to problems such as retained glass fiber on the via walls.

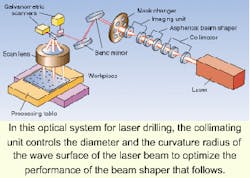

According to Matsushita researcher Koki Ichihashi, these conditions can be minimized by converting the Gaussian beam into a profile with uniform irradiance at the PWB. They chose a dual-lens aspherical beam shaper and tweaked the optical system further with the addition of a collimator to control the property of the input beam entering the aspherical lens system and an imaging unit to project a uniform beam profile on the mask. Other system components include a CO2 laser that outputs linearly polarized light at 9.3 µm, the mask, two-dimensional (2-D) galvanometric scanners, and a telecentric scan lens (see figure).

After the laser resonator outputs the Gaussian beam, the first aspherical lens converts it into a uniform irradiance distribution. The left side of the lens, which directly follows the resonator, is planar in shape. The right side is aspherical. This latter surface has negative power to spread the beam at the center, which weakens the power at the periphery. The second aspherical lens has an aspherical shape on its left side and a plane on the output side. This design modifies the wavefront perturbed by the first lens, producing focused or parallel light rays.

Researchers machined holes of 400-µm diameter in 1.1-mm-thick glass-epoxy PWB. Magnification of the scan lens was 1/25, and the mask was 10 mm in diameter. The laser emitted 70-µs pulses at a pulse-repetition rate of 100 Hz providing 9.5 W at the PWB surface; these conditions allowed the scientists to drill via holes with no residual glass fiber or damage to the copper foil.

About the Author

Paula Noaker Powell

Senior Editor, Laser Focus World

Paula Noaker Powell was a senior editor for Laser Focus World.