PHOTONIC CRYSTALS: SNOM tips yield tunability and insight

One promising avenue in the field of nanophotonics—confining and manipulating light on the nanometric scale—is the use of photonic crystals (PCs) in optical microcavities. Controlling the properties of such photonic-crystal microcavities (PC-MCs), however, is no easy matter. Now, by leveraging the power of scanning near-field optical microscopy (SNOM), straightforward tuning and imaging of PC-MCs has been demonstrated.

Applications for optical microcavities abound, including optical sensing, cavity quantum electrodynamics (QED) experiments, and high-performance optical communication devices. In these cases, the cavities’ Q-factor—an inverse measure of their dissipative losses—is the measure of interest, and it is here that photonic crystals can offer an advantage.

Photonic crystals have optical bandgaps perfectly analogous to the electronic bandgaps in solid-state electronics. The bandgaps can be tuned at manufacture by manipulating the spacing of the array of holes in a dielectric medium that make up the PC. Aggregated quantum dots in the devices act as local light sources, leading to tiny mode volumes and offering the possibility for dense packaging of integrated optical devices with Q-factors that can approach 106, in contrast to the 103 or so of solid-state microcavities.

But the bandgaps and ultimate performance of the devices are hugely sensitive to the manufacturing process and the microscopic character of the processed material—so that the properties of PCs are largely fixed at manufacture. Current manufacturing methods just aren’t sophisticated enough to meet the precision demanded by quantum-physics experiments and the tunability demanded by industrial applications.

So how to tune the properties of PC-MCs after their production? Irreversible methods of post-processing the material, such as further etching of the holes, have been invented. For a more reversible method to modify PC-MC performance, Francesca Intonti of the European Laboratory for Nonlinear Spectroscopy (LENS; Florence, Italy) and her colleagues selectively infiltrated the holes in the PC’s array with liquids (see www.laserfocusworld.com/articles/302488). Through careful choice of the liquids’ refractive index and nonlinear properties, the team achieved selective control of the local dielectric environment, and thus of the individual PC-MC parameters within a slab of devices.1

Changing the cavity mode

Now, Intonti and others have pursued a method first proposed in 2005 by Vahid Sandoghdar at the Swiss Federal Institute of Technology (ETH; Zurich, Switzerland).2 The approach makes use of a scanning near-field-optical-microscope (SNOM) tip both to perturb and to image the modes of their PC-MCs. The presence of the subwavelength tip effectively serves as a local increase in dielectric material. However, the shift of the cavity resonance frequency follows an inverse linear relationship with the polarizability of the tip, whereas the losses induced by the tip’s presence follow a quadratic relationship. Therefore, the cavity mode can be significantly changed without inducing much loss, preserving the cavity’s high Q-factor.

The PC-MCs consisted of three layers of indium arsenide quantum dots suspended at the center of a 320-nm-thick gallium arsenide (GaAs) membrane. Four missing holes in a diamond shape in the middle of a triangular hole array constituted the microcavity region of interest. The group used a glass SNOM tip to collect the photoluminescence signal of the quantum dots, and found that the presence of the tip controllably perturbed the local dielectric constant of the PC-MCs—the presence of the tip effectively served as a local increase in dielectric material, resulting in a few-nanometer red-shift of the cavity mode.

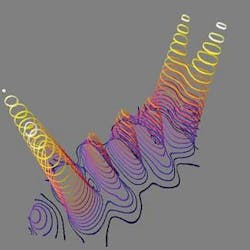

They found that the shift can be dynamically controlled by varying either the distance of the tip from the PC-MC surface or the intensity of the light coupled into the SNOM tip. “Due to the fact that the strength of the tip-induced tuning is proportional to the intensity of the electric field associated to the microcavity eigenmode, the spatial map of the tuning strength gives a direct imaging of the spatial distribution of the microcavity eigenmodes with spatial resolution down to l/6,” Intonti says. The result is a means of characterizing devices with unprecedented detail.

Local change of refractive index

Because the presence of the SNOM tip slightly broadens the cavity’s linewidth, a spatial map of tip-induced losses can be obtained.3 A further effect that the team noticed is that the laser light coupled into the tip can increase the temperature of the microcavity, leading to a local change of the refractive index of GaAs, changing the location at which the cavity would otherwise experience local heating, thereby providing a further tuning parameter.4

“The local, continuous, and reversible nature of the tip-induced tuning, in contrast to other tuning mechanisms, can be exploited in the field of quantum electrodynamics, where single atoms are strongly coupled to single cavity modes,” Intonti says. “Once the right conditions are met, the reversible nature of this mechanism could allow switching the system into and out of the strong coupling regime. Similarly, it can be used to realize photonic-crystal-based switches and to modify the range of operation of photonic devices, like add/drop filters or low-threshold lasers, integrated in a 2-D photonic-crystal slab.”

Because the method generates previously inaccessible information about the cavity modes, the researchers intend to use it to more fully characterize the devices they can make with their prior liquid-infiltration approach.

“It’s nice work, with clean tuning, and the agreement with theory makes a lot of sense,” says Vahid Sandoghdar. He concedes that the technical difficulty of integrating PCs with SNOM technology puts practical application some time in the future. For the present, the result is most interesting for cavity QED experimenters who will be able to tune their PC modes to those of the quantum dots within with unprecedented ease.

However, with the approach fully characterized, he says that multifunctional, integrated nano-optical systems like optical filters and switches could simply be a matter of marrying PCs with existing microelectromechanical technology. The idea would be to use individually addressable tips actuated by cantilevers. “For those applications, the thing is all about speed, and you’d be dealing with something mechanical,” he says. “There’s no reason why you couldn’t reach tens of megahertz using cantilevers with tips on them.”

REFERENCES

1. Intonti et al. Appl. Phys. Lett. 89, 211117 (2006).

2. Koenderink et al. Phys. Rev. Lett. 95, 153904 (2005).

3. Intonti et al. Phys. Rev. B, in press.

4. Vignolini et al. Appl. Phys. Lett., in press.