OPTICAL INTERCONNECTS: Hybrid tunable silicon laser has integrated EAM

The world’s largest semiconductor company, Intel (Santa Clara, CA), is actively pursuing development of optical interconnects for use in and between computers. Researchers at Intel and the University of California, Santa Barbara, have developed hybrid silicon lasers that consist of a III-V semiconductor active device bonded to a silicon (Si) chip containing silicon dioxide (SiO2) waveguides.1 The laser light is evanescently coupled into the waveguides.

The key to the Intel device is that it is the first tunable laser on Si, and in addition is the first integration of such a laser with an external modulator on Si. The device has multiple III-V bandgaps, allowing the monolithic construction of a laser active region, mirrors, and phases and modulator regions in a single small unit. The III-V semiconductor platform used is indium gallium arsenide phosphide/indium phosphide (InGaAsP/InP).

Quantum-well intermixing

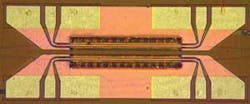

The researchers have created hybrid Si multisection sampled-grating distributed-Bragg-reflector (SGDBR) lasers and hybrid Si SGDBR lasers with monolithically integrated electroabsorption modulators (EAMs). The lasers contain five sections, each with its own bandgap: a front mirror, a rear mirror, a gain region, a phase region, and a backside absorber. The differing bandgaps are created during fabrication using a quantum-well-intermixing (QWI) process.

Even after fabrication on its InP substrate, the laser does not have a well-defined cavity; although it has gratings, multiple quantum wells (MQWs), mirrors, and so on, the cavity has no lateral edges. In fact, only when the III-V chip is bonded to the Si wafer is the complete cavity formed, sides and all. This is because the Si wafer’s waveguide, which is oriented perpendicular to the laser gratings on the II-V chip, forms the cavity sides through evanescent coupling after the two pieces are bonded together. Because both the gratings and waveguides are one-dimensional patterns, only rotational alignment is needed during the bonding process.

After bonding, the laser is further processed, including InP substrate removal, mesa etch, electrical isolation of the various laser sections (with their differing bandgaps) by proton implantation, and other steps. Finally, the laser waveguides are diced, polished, and antireflection coated.

The prototype SGDBR laser has a 1.0-µm-wide Si waveguide, a threshold current of 48 mA, and lases at temperatures up to 30°C (emitting 1.0 mW at 10°C). It can be tuned over three cavity modes, spanning a range of 1501 to 1514 nm. The tuning range will be improved by adding more quantum wells, along with a tuning layer in the laser structure.

The first integrated SGDBR-EAM has a 2.5-µm-wide Si waveguide, produces up to 0.5 mW continuous-wave at 10°C, and emits at up to 45°C. (The difference in maximum operating temperatures between the two devices—30°C versus 45°C—falls within the variation observed for all tested devices, and is thus likely not of particular significance.) The SGDBR-EAM tunes over four supermodes, reaching wavelengths of 1524, 1518, 1512, and 1554 nm at a side-mode suppression of greater than 35 dB. The bandwidth of the integrated modulator reaches above 2 GHz at a bias of 6 V (more quantum wells will boost the bandwidth).

Next: gratings in silicon

“Although the gratings in the tunable laser are fabricated on the III-V, our long-term goal is to integrate as much processing as possible in silicon,” says Matthew Sysak, one of the Intel researchers. “Patterning gratings in silicon is very attractive since we can take advantage of the lithography capabilities that are available in our CMOS manufacturing facilities.”

Sysak notes that in telecommunications, the area of dense wavelength-division multiplexing (DWDM) is just now moving toward integration of modulators with tunable lasers, so the integrated SGDBR-EAM could become a useful component in wide-area and metro networks, and maybe local-area networks.

“More important, though, is that this is a demonstration of a very flexible integration technology for integrating a wide variety of devices into a single silicon photonic integrated circuit,” says Sysak. “Using QWI in our silicon-photonics toolbox, we have the ability to fabricate a whole host of new optical components that were previously not available. These new components include things like electroabsorption-modulated lasers, tunable lasers, and wide-optical-bandwidth laser arrays. These devices are attractive for very compact, high-date-rate silicon transmitter chips and silicon transmitter chips that do not require temperature stabilization, and these may be the basis for memory or video interconnects or for future interchip and intrachip communications.”

Inside the computer

At this time, the group does not envision the SGDBR-EAM becoming part of the Intel CPU, but according to Sysak, it has value as part of the computer platform. “One of the benefits of the hybrid silicon tunable laser is that it has the ability to change operating wavelengths, or ‘colors,’ quickly and with low electrical power,” he says. “One could imagine that a silicon-based tunable laser with integrated modulator could be used to communicate between a CPU and a bank of external memory, or a CPU and a graphics processor. In such a scenario, each of the different colors from the laser might be dedicated for a particular link. Since the colors can be changed rapidly and efficiently, data could be routed with low power and low latency.” Another potential use of the SGDBR-EAM is as part of an array of tunable laser sources for WDM data communication within a computer.

“One of the other attractive attributes of the QWI-based tunable laser modulator is that it can be easily integrated with other world-class silicon photonic components,” Sysak adds. “On the photodetector side, these components include Intel’s silicon-germanium avalanche photodetectors or p-i-n photodetectors, as well as hybrid photodetectors fabricated with the same technique we used for this QWI laser.”

REFERENCE

- M.N. Sysak et al., Optics Express, 12478 (Aug. 18, 2008).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.