No-heat molding makes lasers in minutes

Semiconductors can be in polymer form and these materials can serve as gain media for lasers. The result may someday be simple, low-cost optically pumped lasers that can become part of optoelectronic integrated circuits (OEICs). Researchers at the University of St. Andrews (St. Andrews, Scotland) have developed a distributed-feedback (DFB) version of this type of device that is especially easy to fabricate.1

Such lasers have been made before, by spin-coating a film onto a substrate fabricated either by traditional photolithographic techniques or by replication via ultraviolet (UV) embossing. The former method is complex and expensive, while the latter has limitations that arise from the UV-curable substrate materials required. Not only does a UV-curable polymer substrate have a refractive index very close to the gain medium, making waveguiding difficult, but such substrates would be difficult to eventually integrate electrical contacts into for OEICs.

In the new fabrication technique, the active polymer is directly patterned by solvent-assisted microcontact molding (SAMIM), which does not require any potentially damaging heat processing. A 100-nm-thick film of semiconducting conjugated polymer called OC1C10-PPV is spun onto a glass substrate (alternatively, a thicker film can be drop-cast from solution). A separate elastomeric mold (the "stamp") containing a crossed DFB grating is cast from a master mold. The stamp is then inked with chlorobenzene solvent and placed in contact with the semiconducting polymer film. Within two minutes, the solvent on the stamp dissolves the polymer, then evaporates by diffusing into and through the stamp.

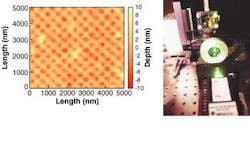

The resulting laser consists of a uniform two-dimensional grating with a period of 400 nm (see figure). The refractive index of the polymer is close to 2, while the glass has an index of 1.46, allowing waveguiding to occur.

Justin Lawrence, one of the researchers, attributes the survival of the features in the crossed grating made by SAMIM at least partially to something in the structure of the grating itself. "Most attempts at making submicron features with [elastomeric] molds try to replicate gratings or ridges. Our structure is a crossed grating (two gratings at 90° to each other), which might provide extra support that reduces collapsing and merging," he notes.

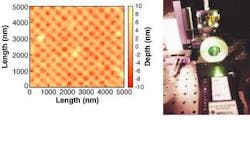

The laser is pumped with 532-nm light from a frequency-doubled passively Q-switched Nd:YVO4 (vanadate) microchip laser that produces 1-ns pulses at a 5-kHz repetition rate. The emission wavelength is 638 nm. Second-order Bragg scattering provides back-reflection within the film to form the laser cavity, while first-order Bragg scattering causes surface emission of the laser light approximately normal to the plane of the laser. "We have not measured the output beam profile of this particular laser," says Lawrence. "Similar lasers made with microstructured silica substrates and the same polymer give an annular-profile transverse mode."2

One advantage of the fabrication technique is its versatility. "It could be used to easily replicate any pattern in many different polymeric materials, so one could make a wide range of integrated polymer photonic devices," says Lawrence. As for future research, he adds that because the gain medium is directly patterned, corrugated electrical contacts would not be required to make a polymer laser diode.

REFERENCES

- Justin R. Lawrence et al., Appl. Physics Lett. (June 9, 2003).

- G. A. Turnbull et al., Appl. Physics Lett. 20 (January 2003).