Diamond-like carbon boosts IR transmission

TOKYO—Kyocera Optic has developed high-hardness, high-transmittance coating technology for infrared (IR) lenses and is developing a sample for IR camera lenses. Germanium (Ge) and silicon (Si) are materials typically considered to be superior for many IR lenses. Exploiting the polishing technology the company has developed over many years, Kyocera has created a lens for a high-resolution IR optical system that is capable of clearly detecting objects 200 m away. However, this lens is expensive and prone to scratching. Such lenses are used in special circumstances that require very high resolution, such as monitoring ships, but are rarely use in day-to-day applications.

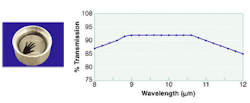

The newly developed technology involves laying down a 1-µm-thick coating of diamond-like carbon (DLC). This coating has a relatively high degree of diamond bonding, so it possesses high hardness. In addition, it sticks well to the lens. When one side of a Ge element is coated with a DLC film and the other side is coated with an antireflection coating, the transmission is typically over 90% for 8- to 12-µm wavelengths (see figure).

null

The characteristics of the coating are guaranteed over a temperature range of -35°C to +115°C; the coating has passed rubber-pumice scratch testing. This coating technology enables high-sensitivity IR recording over long periods of time. In addition, the low-temperature vapor-deposition method used to fabricate the coatings can be adapted for mass production, which should lead to reduced cost.

High-sensitivity IR sensors are already used in some luxury cars equipped with night-vision systems and other uses are planned for the future.

Courtesy O plus E magazine, Tokyo