Designers of thin-film coatings know that the number of layers in a high-reflection coating can be reduced (or, conversely, the reflection increased) if the difference in refractive index between the high- and low-index layers is increased. A few years ago, researchers at the Universität Würzburg (Würzburg, Germany) took this technique to the extreme, reducing the number of layers in the cavity mirror of an edge-emitting laser diode by alternating layers of air with laser material to create a short distributed Bragg reflector (see Laser Focus World, November 1999, p. 18). The approach allowed them to create end mirrors without having to cleave the laser ends into facets.

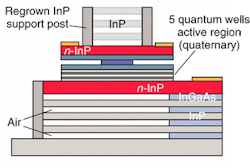

Now, researchers at Agilent Laboratories (Palo Alto, CA) are using the same approach in making 1.3- to 1.5-µm-emitting vertical-cavity surface-emitting lasers (VCSELs). Fabricated monolithically on semiconductor substrates, VCSELs consist of dozens of thin-film layers, many of them making up the cavity mirrors. Although the materials that go into ordinary VCSELs emitting at 850 nm allow for easy manufacture of high-reflection layers, the creation of longwave VCSELs has been hampered by the lack of material combinations for high-quality thin-film mirrors. In the Agilent approach, indium phosphide (InP)-based VCSELs are fabricated with mirrors that contain three or four air layers—a simple structure, yet one that has the high-reflectivity that up until now has been so hard to achieve (see figure).

To make the mirrors, layers of indium gallium arsenide (InGaAs) are grown in an alternating fashion with layers of InP, then the InGaAs etched away. Some InP is then regrown into part of the undercut areas to mechanically stabilize the structure. While the mode-defining apertures in ordinary VCSELs are buried within the lasers' solid structure—for example, apertures that consist of an oxide layer—in the case of InP, oxide cannot be used, so the aperture in the Agilent device is defined by an air undercut. The laser has no disadvantage in heat removal compared to conventional VCSELs as a result of the thick InP layers used, says Michael Tan, project manager at Agilent.

Versions of the laser were made that operate in the 1300- and 1560-nm regions. Room-temperature output powers reach 1.9 mW for 1300-nm emission and 1.2 mW for 1560-nm emission. Such outputs are the highest yet achieved for longwave VCSELs, notes Tan.

The lasers emit at temperatures up to 75°C at reduced powers of about 0.2 mW. Standard quaternary materials have low characteristic temperatures, causing thresholds to rise quickly with temperature; the Agilent researchers are working on ways around this problem. One approach is to go to an aluminum indium gallium arsenide active region, says Tan. The group is also looking into how to reduce the voltage across the laser's tunnel junction.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.