Tunable filters facilitate nondestructive analysis of art

Nondestructive analysis is vital to the characterization, preservation, and restoration of works of art. A number of spectroscopic tools and analysis techniques are currently available to art historians, conservators, museum curators, archaeometrists, anthropologists, and owners of both private and public collections. Varied in nature and function, such multispectral-detection techniques include Fourier-transform infrared spectroscopy, polarized-light microscopy, x-ray diffraction, x-ray fluorescence, gas chromatography, high-performance liquid chromatography, infrared (IR) spectroscopy, ultraviolet radiation, and IR reflectography.

The spectroscopic examination of works of art is intended to reveal crucial information about the physicochemical aspects of work materials as well as the methods used in construction.

null

A common aim of examination is pigment detection and identification (see Fig. 1). This information is required when attempts are made to reconstruct the original appearance of a work that has degraded over time. Pigment analysis can also help advance knowledge of which materials were used during a certain time period and/or in a certain geographical region, aid in dating works, and even expose masterpiece forgeries.

It is essential that this type of investigation be noninvasive and that the work of art not be damaged or compromised in any way during characterization. Currently, only about a dozen museums in the United States have their own conservation laboratories. Furthermore, the transportation of precious—and sometimes priceless—works of art to a laboratory is often neither possible nor desirable. Significant advance can be realized in the nondestructive spectroscopic detection and identification of pigments by development of portable hyperspectral imagers capable of operation in the near- and mid-infrared, specifically between 1 and 4 µm, with spectral resolution of approximately 10 nm.

Many approaches

In an effort led by one of the authors (Edward Cloutis), Scientific Solutions (SSI) was recently commissioned to research and design an instrument destined for mapping a broad distribution of pigments on both paintings and manuscripts. The challenge of the instrument design is to sample roughly 300 discrete spectral elements across an extremely broad operating range. The device must be able to image paintings as large as 1 m2 with a minimum signal-to-noise ratio of 200:1. Drawing on SSI's experience in spectroscopic devices and consulting, this study considered all options presented by current technology, including conventional gratings, static interference filters, liquid-crystal tunable filters, acousto-optic tunable filters, and air-gap, piezoelectric, and liquid-crystal Fabry-Perot interferometers.

Conventional gratings disperse light from a target along a single linear or curved dimension. A multicolor image of the target can then be constructed by physically moving the detector's field of view across the target. Independent of their mechanical deficiencies, both push-broom and rotating spectrographs would require a large footprint to achieve the required spectral resolution and throughput. These systems would not only be bulky but also difficult to transport and assemble, thereby not meeting the portability requirement. Although relatively inexpensive, the use of conventional grating technologies and mechanical scanning is not a viable option for the intended device.

A common imaging system consists of an array detector positioned behind fast optics and a series of static interference filters that isolate spectral regions of interest. While this option is indeed attractive by virtue of its simplicity, a minimum of 300 static filters and a complex mechanism to successively move each filter into the optical path would be required to satisfy the instrument design specifications. Such a configuration is neither acceptable nor cost-effective.

Liquid-crystal tunable filters (LCTF) are essentially stacks of polarization-sensitive retarder cells, with multiple stacks required for high spectral resolution. To meet the desired instrument specifications, this type of device would require about seven cavities, resulting in an ultimate transmission of roughly 5%. Furthermore, use of the LCTF technology beyond about 3.2 µm is precluded by strong absorption in the liquid-crystal material. Although easily tunable with electronic control and available in large diameters, LCTF technology cannot simultaneously achieve the spectral resolution and throughput required for the intended device.

Acousto-optic tunable filters (AOTFs) are low cost, but suffer a physical size constraint caused by the practical size limit to which crystals can be grown. In addition, physical peculiarities of acousto-optic interaction are known to exist in the IR. Comparatively, image quality of the AOTF is poor and sensitivity is limited by a restrictive field of view and low overall transmission. Acousto-optic tunable-filter technology is still in the process of undergoing significant research and development. In their current state, SSI concludes that AOTFs are not an ideal option for the intended device.

Classic Fabry-Perot (FP) interferometers have the intrinsic quality of providing high spectral resolution while preserving image quality and yielding maximum throughput for a given spectral resolution. The most basic version of a tunable FP system has an air gap that is tuned by changing the pressure within the resonant cavity. This type of tuning requires a very large pressure piston, violating the design conditions of portability and simplicity of use.

Another version of a tunable FP uses piezoelectric spacers in the resonant cavity to adjust gap thickness and thus transmitted wavelength. Piezoelectric FPs (PEFP) have air in the resonant cavity, and no absorption problems across the entire 1- to 4-µm range. The instrument is polarization-insensitive, and large apertures are possible. A PEFP can thus provide excellent throughput across the entire specified spectral range. Unfortunately, maintenance of plate parallelism has been a historic challenge for PEFP and complex power-intensive active feedback mechanisms are commonly used for constant recalibration. Piezoelectric FPs can be bulky, awkward to operate,phenomenally expensive, and arguably lack the mechanical stability required for portable applications.

Two LCFPs in one instrument

The liquid-crystal Fabry-Perot has liquid crystal rather than air in the resonant cavity, a dramatic improvement over the classic FP interferometer. Changing the index of refraction of the liquid crystal by applying a low-voltage electric field is effectively equivalent to changing the physical distance separating the mirrors. The result is a completely solid-state, robust, compact, easy-to-use, tunable optical filter with high spectral resolution and rapid, precise, stable spectral selection. Although capable of delivering the required spectral resolution and high throughput, the LCFP suffers the same disadvantage as the LCTF: liquid-crystal absorption beyond 3.2 µm limits spectral coverage to only 73% of the desired range.

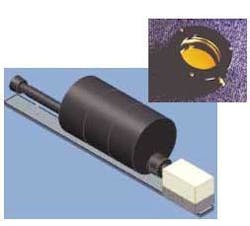

Having evaluated all options, SSI concluded that tunable FP systems are indeed the best prospect for the dispersive element of the intended imaging system. The ultimate design relies on two LCFP tunable filters and a series of 31 static interference filters in three filter-wheel assemblies for wavelength selection (see Fig. 2). Other elements in the system include imaging optics, a collimator, and an indium antimonide (InSb) focal-plane array. Of the numerous detectors considered, only those made of InSb are capable of high quantum efficiency over the entire operating range. An additional feature of the detector circuitry is the ability for nondestructive readout, which allows for dynamic integration periods; it is possible to integrate until a desired signal to noise is achieved and then read out the image. Interchangeable foreoptics allow for flexibility when working with either large works such as paintings or smaller works such as manuscripts. A photographic-quality light source is employed to evenly illuminate a 1-m2 region when placed at a distance of 1 m. The entire system is computer controllable.

The use of two distinct LCFPs is necessitated by both the inability to achieve a partially reflecting coating that continuously covers both the near-IR (NIR) and mid-IR (MIR) regions and the constant spectral resolution specification across the entire operating range. Nearly constant resolution is achieved by employing a smaller gap in the NIR LCFP than in the MIR LCFP. To optimize transmission, the NIR LCFP is fabricated using IR fused-silica substrates while the MIR LCFP is fabricated using zinc selenide substrates. Each filter has a 51-mm outer diameter with a 38-mm clear aperture. Seated in a thermally controlled housing, the total filter outer diameter is roughly 3.75 in. The LCFPs can be quickly and easily swapped on a bayonet mount when changing from the NIR to the MIR.

Three precision motorized filter wheels are placed between the collimator and the LCFP. Each filter wheel is capable of holding up to 12 1.5-in.-diameter narrowband all-dielectric multiple-cavity image-quality interference filters. These "order-sorting" filters operate in tandem with the LCFP to isolate a single order centered on the spectral band of interest, over which the LCFP tunes. All the order-sorting filters required for operation with either LCFP etalon are contained within these three filter wheels; an empty position in each wheel allows access to any filter in the entire assembly.

The recommended imaging system successfully blends the requirements of mechanical stability, portability, high-spectral resolution, high luminosity, and moderate cost. The system is compact, mechanically robust, requires only a few watts of power, and is easy to set up on a robust optical tripod at a given field location. The proposed system promises to break new ground in the nondestructive analysis of art while adding to the available spectroscopic tools required for art conservation and restoration.

MICHAEL DORIN is an applications engineer at Scientific Solutions, North Chelmsford, MA 01863; e-mail: [email protected]. EDWARD CLOUTIS is associate professor of the Department of Geography and director of the Centre for Forest Interdisciplinary Research at the University of Winnipeg, Manitoba, Canada R3B 2E9; e-mail: [email protected].