Optical nanocomposite is suited for photonics packaging

Optically transparent materials are needed for the low-cost packaging of photonic components and modules. Critical properties required for those packaging materials include controlled refractive index, low cure shrinkage, and a coefficient of thermal expansion (CTE) matched to that of the associated photonic components.

Conventional polymeric optical packaging materials tend to have high shrinkage and large CTEs, limiting their applications. One way to reduce the CTE and minimize associated problems is to incorporate glass particles into the polymer. Addition of a glass filler, however, usually causes light transmittance to be lost—a result of the difference between the refractive index of the particle and that of the epoxy matrix.

Some researchers have reported that when the refractive index difference is reduced to the order of 10-3, optical transparency can be achieved.1, 2, 3 Recently, nanometer-sized silica particles have been used instead of the typical micron-sized particles.5 Here, we introduce a new type of optical nanocomposite for photonic packaging and device applications. The CTE and the light transmittance of these optical nanocomposites are determined as a function of filler fraction.

Nanocomposite fabrication

The matrix of the nanocomposites is an epoxy-resin system. The resin used in the experiments was a clear-grade diglycidal ether of bisphenol A (BADGE). The hardener was substituted hexahydro-phthalic anhydride; a tertiary amine salt was used as a catalyst. The nanometer-order silica filler has a narrow particle-size distribution with a most populated size of approximately 25 nm. The maximum particle size is 50 nm. The nanoparticles were predispersed in BADGE.

The bulk material was prepared by mixing the epoxy resin and the predispersed nanometer-order silica with a stoichometric quantity of hardener and catalyst. The resulting composite was de-aired, poured into 30-cc syringes, and frozen at –40°C until use. To study the effect of particle fraction on CTE and light transmittance, bulk materials with 0%, 5%, 10%, 20%, and 30% (by weight) of nanosized silica were formulated.

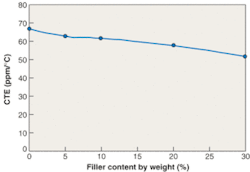

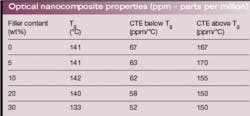

Test samples were prepared by thawing the premixed and frozen epoxy material for one hour at 25°C in a temperature-controlled water bath, casting the thawed material into steel molds previously treated with a silicone mold release. The cure schedule was determined by a differential-scanning-calorimeter study to be 2.5 hours at 125°C. The final thickness of the specimens for light-transmittance measurements was 3.1 ±0.2 mm; their surfaces were polished using 800-grit silicon carbide and finished with 0.3-µm deagglomirated alumina polish.Glass-transition temperature (Tg) and CTE were determined using a thermomechanical analyzer (an instrument that measures mechanical properties such as dimensional changes as a function of temperature). All samples except the one with a 30% fill were determined to have a similar Tg (see table); the reason for the lower Tg in this one instance needs to be further investigated. As expected, the experimental results show that as the filler content goes up, the CTE goes down (see Fig. 1).

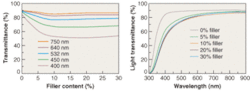

Transmission stays high for increased filler

When samples of the composites are placed on characters printed on paper, the characters are legible, suggesting that the composites transmit light well in the visible wavelength region. A spectrophotometer was used to determine the light transmittance over a range of 300 to 900 nm (see Fig. 2). Generally, addition of fillers reduces the light transmittance; however, the magnitude of the reduction is wavelength dependent. The filler addition causes light transmittance to be reduced more for shorter wavelengths.The spectral transmittance of the nanocomposites as a function of filler content slopes more steeply at shorter wavelengths; as the wavelength becomes longer, the particle size of the filler becomes much smaller than the wavelength, causing much less reduction in light transmission. Another interesting experimental finding is worthwhile to mention: as the filler content is increased beyond 10%, no additional reduction in light transmission is observed. Such a phenomenon may be explained by percolation theory (which describes the effects of interconnections within a random system). Further investigation is needed for a full explanation of this effect.

Adding a nanometer-order silica filler to an epoxy matrix is a feasible way to make optical nanocomposites for packaging applications, especially in light of the discovery that increasing filler content beyond 10% by weight does not seem to further drop the light transmittance. There are many other opportunities in this field, such as the in situ synthesis of nanoparticles.6, 7

REFERENCES

- H. Sato and Y. Kagawa, Jap. Soc. for Composite Material, Tokyo, (1995) 663.

- T. Naganuma, H. Iba, and Y. Kagawa, J. Materials Science Lett. 18, 1587 (1999).

- Y. Kagawa, H. Iba, M. Tanaka, H. Sato and T. Chang, Acta mater. 46(1), 265 (1998).

- T. Naganuma and Y. Kagawa, Acta mater. 47(17) 4321 (1996).

- T. Naganuma and Y. Kagawa, Composites Science and Tech. 62(9) 1187 (2002).

- Mikrajuddin, I. W. Lenggoro, K. Okuyama, and F. G. Shi, J. Electrochemical Society 149(5) 107 (2002).

- Mikrajuddin, I. W. Lenggoro, K. Okuyama, and F. G. Shi, J. Chem. B, 107, 1957 (2003).

FRANK G. SHI is a professor of chemical engineering and materials science and YAN ZHOU is a doctoral student at the University of California-Irvine, Irvine, CA 92697; e-mail: [email protected]. MAURY EDWARDS is a senior fellow at Henkel Loctite, 15051 E. Don Julian Rd. Industry, CA 91746.