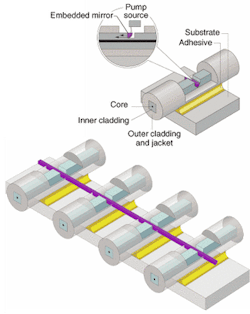

Embedded mirror launches pump light into cladding

Rare-earth-doped fiber lasers and amplifiers are beginning to displace conventional bulk lasers in numerous existing applications, and they are enabling new applications in areas such as materials processing and chemical detection. Double-clad fiber is helping to scale fiber sources to higher powers and pulse energies because the large multimode inner cladding facilitates the use of higher-power and lower-cost multimode pump sources.

Schemes that have found widespread use for launching pump light into double-clad fiber include end pumping, which launches pump light into one or both ends of the fiber; fused fiber bundling, in which several multimode fibers are fusion-spliced to the inner cladding; and V-groove side pumping, in which the pump beam is launched by total internal reflection from a V-shaped groove cut into the inner cladding, according to Dahv Kliner, a researcher at Sandia Laboratories (Livermore, CA).

Shortcomings of these pumping methods include obstruction of the fiber ends and limited scalability for end pumping; the need for double-clad fiber and a fused bundle with matching dimensions for fused fiber bundling; and relatively high alignment sensitivity for V-groove side pumping, said Kliner, who has collaborated with Jeff Koplow and Sean Moore of the Naval Research Laboratory (NRL, Washington, D.C.) to develop a new method of side pumping through a micromirror embedded in the inner cladding (see figure).1

The embedded mirror consists of an isosceles right-triangular piece of glass inserted into a channel cut into the inner cladding of the double-clad fiber. The pump beam enters the exposed face of the mirror, bounces off the curved and high-reflection-coated hypotenuse, and launches into the fiber though the third face. The NRL/Sandia team developed the embedded-mirror side-pumping method specifically to address the limitations of other techniques, while also addressing a broad range of critical performance specifications.

Kliner's list of considerations for evaluating the suitability of a pumping scheme for a given application includes pump-coupling efficiency, short- and long-term stability, alignment sensitivity, compactness, simplicity, scalability, compatibility with a wide variety

of double-clad fibers and pump sources, obstruction of the fiber ends, and cost. "In many cases, the pumping scheme must simultaneously address all of these considerations, and poor performance in any category will render the approach unsuitable," he said. "Pumping of double-clad fiber thus remains a significant issue for many applications."

Primary advantages of the new method include its flexibility and ease of implementation resulting from large alignment tolerances (similar to butt-coupling of multimode fibers) and a low parts count based on relatively inexpensive optical components and mounting hardware, Kliner said. "The mirrors are fabricated by drawing an appropriately shaped preform in a manner similar to that used for drawing conventional optical fiber. So a single drawing run provides thousands of mirrors in a variety of sizes without requiring a new drawing or coating run for each amplifier."

In addition, fiber pigtailing of the pump diodes is not required, and the technique permits use of highly divergent pump diodes, including those with a numerical aperture larger than that of the inner cladding of the double-clad fiber. The research team ultimately hopes to directly couple the emission from a diode bar into double-clad fiber to allow cost-effective fabrication of high-power amplifiers or multiple amplifiers sharing a single pump source. "We're also continuing to refine the technique to provide even higher coupling efficiency," said Kliner.

For more on fiber lasers, see p. 85.

REFERENCE

- J. P. Koplow et al., IEEE J. Quant.Elect. 39(4) 529 (April 2003).