Sol-gel methods can yield complex, economical optics

Sol-gel methods can yield complex, economical optics

Molded silica micro-optics based on a sol-gel process offer a practical alternative to optics made by conventional fabrication techniques.

Jean-Luc R. Nogus and Peter B. Hunt

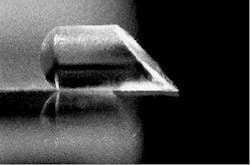

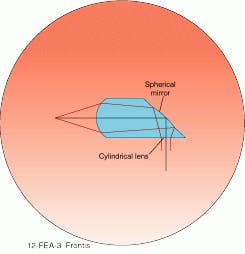

Sol-gel microlens for variable-focus endoscopic surgical instrument has a convex spherical refractive entrance face, a mirrored turning/focusing face, and a side cylindrical exit face (bottom right). The angled entrance face consists of an internal mirror with a concave spherical portion (top right) that concentrates and directs the beam to the cylindrical refractive exit face.

ystem designers in the laser industry know the benefit of using silica components for their most demanding optical applications?silica offers a broad transmission range, low thermal expansion, and mechanical strength. But traditional machine finishing of silica micro-lenses is a labor-intensive process that requires skilled personnel and can represent 80% to 90% of the component cost. The sol-gel process, offers a practical, economical avenue to the benefits of silica micro-optics.

Sol-gel optical fabrication is a molding process that requires no additional finishing work, reducing production steps and costs. Sol-gel optics are replicated in bulk from a single tooling, making the process particularly cost effective for production of small or complex, high-purity silica optics. Geltech Inc. (Alachua, FL) developed a sol-gel process to produce these materials and currently supplies customed-designed and off-the-shelf silica components under the trade name Gelsil for a variety of applications. These components may soon be available through catalogs, as are increasing numbers of optical components (see OOptical-component catalogs go on-line,O p. 92).

Manufacturing sol-gel lenses

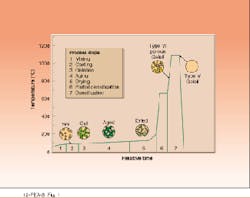

The sol-gel process can be divided into three parts: sol and gel formation, drying, and densification. Chemical ingredients are mixed to produce a sol with a viscosity only slightly greater than water (see Fig. 1). The sol is poured into molds. Hydrolysis and polycondensation of the sol form the three-dimensional network of the future glass, and the solution stiffens into a Owet gel.O To develop and strengthen the initial texture of the material, the gel is left in the mold to age. After aging, a further drying step eliminates the interstitial liquid from the gel body. Finally, the dry gel is heat-treated to change the porous solid into a dense homogeneous glass. No additional finishing is required.

During aging, drying, and densification, the gel shrinks by a factor of 2.5 (see Fig. 2). Because it is process controlled and uniform in all three linear dimensions, this shrinkage is a significant advantage, making it possible to fabricate micro-optics with features smaller than those machined into the tooling/mold. In addition, imperfections and tool marks imparted to the element by the mold surface decrease in size during shrinkage, actually improving the surface finish of the sol-gel optic over that of the mold.

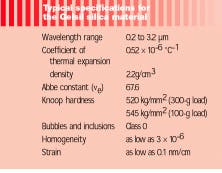

Silica optical elements produced by this process have low thermal expansion, excellent mechanical strength, hardness, chemical durability, and high transmission over the spectral range from 0.2 to 3.2 ?m (see table on p. 93).

Economical optics fabrication

Because sol-gel replication is essentially a molding process, it requires tooling and molds. Geltech engineers design the tooling, essentially an oversized version of the customer-specified optic. To accommodate shrinkage, the tooling must be dimensionally scaled up by a factor of 2.5. The tooling for a 1-in. optic, for example, must be designed to produce a

2.5-in. mold.

Toolings are fabricated by conventional methods such as precision grinding, diamond turning, and photolithography. Though such processes can be expensive, the cost of tooling is only incurred once and can be amortized over a large number of parts. In high-volume applications, cost per unit is kept low. Moreover, aspheric or nonrotationally symmetric elements can be made as cheaply as conventional lenses.

A large number of plastic molds are made from the completed master tooling by common plastic-forming techniques such as compression or injection molding. Initial prototype optics are inspected for quality, and, if necessary, minor adjustments are made in either the mold or the processing procedure. Current tolerances allow the finished cast part to vary only by about ?1% to 2% from the design specifications.

Complex micro-optic components

Micro-optics with aspherical, cylindrical, or other diffractive surfaces can be produced with a sol-gel method. Designers can also specify multisided elements with orienting grooves or mounting flanges. These options, often unavailable with machined components, can permit designers to simplify and miniaturize optical systems. Engineers have been able to develop application-specific products that take advantage of the benefits of a sol-gel method, such as a novel lens for fiber-delivered laser surgery systems.

The lens, part of a variable-focus endoscopic surgical instrument produced by Reliant Technologies Inc.

(Foster City, CA), solves many of the beam-control problems inherent in the design of medical laser instruments. Connected to the end of an optical fiber, the Laser Sweep Tip is a silica microlens with a convex spherical refractive surface

(R = 1.6 mm), an internal mirror surface with a concave spherical radius of 12.8 mm, and a cylindrical refractive surface on the side exit face (see photo, p. 90). The optic is 2.8 mm in diameter and 5.9 mm long. A laser beam coupled from fiber to lens is collimated by the convex refractive surface. Light propagates through to the angled lens face, where it is concentrated and turned by the internal spherical mirror to exit through the cylindrical lenslet.

In surgery, the doctor holds the unit like a pencil. By positioning the instrument so that the target area is at focus or through focus, the surgeon can switch between a tightly focused cutting beam or a diffuse coagulation beam. The element is optimized for use with an Nd:YAG laser providing a maximum of 40 W of power at 1.06 ?m.

Diffractive optics from a beaker

Diffractive elements such as blazed gratings and binary optics can be used to divide single beams into multiple beams, couple laser-diode array output into a single beam, spread or diffuse a beam, or correct aberrations imparted by refractive lenses. Although micro-optical components with these surface features are available in both plastic and micromachined quartz or glass, both materials have drawbacks. Plastic has limited durability, transmission, and bandwidth, while the expense of machining quartz or glass micro-components makes this approach useful only for very limited production. With the sol-gel process diffractive silica micro-optics can be economically produced in volume.

Geltech currently offers Fresnel lenses, blazed gratings, and binary optics with submicron resolution. In a variation to basic optic production, the company developed a hybrid diffractive/ refractive silica micro-optic in collaboration with researchers at Oak Ridge National Laboratory (Oak Ridge, TN, see Laser Focus World, Oct. 1995, p. 20). Corrected for both spherical and chromatic aberration, the hybrid optic is used in the ultraviolet and visible spectral regions. Like other sol-gel optics, it can be produced in high volume. Hybrids have uses in military, space, and high-radiation applications, as well as consumer and medical products.

For example, many illumination systems now use inexpensive, conventionally fabricated condenser lenses. Molded silica condenser lenses made by a sol-gel process offer equivalent performance for less than one half the cost of the machined version.

Sol-gel silica micro-optics can be incorporated in ultraviolet, visible, and infrared designs for spectroscopy, communications, and medical laser equipment. Other applications include consumer and industrial electronics, remote sensing equipment, and laser systems. As designers and engineers become familiar with the capabilities of sol-gel components, more off-the-shelf silica micro-optical components will emerge from their custom designs. This should further enhance both the mass production and the cost advantages of micro-optics produced through the sol-gel process. n

FIGURE 1. In a sol-gel process, a mixture of chemicals is poured into a mold and allowed to harden. After unmolding, the newly formed optic is dried and exposed to high heat to eliminate air gaps and increase density in a process termed densification.

FIGURE 2. Because the finished sol-gel optic (left) shrinks by a factor of 2.5, the corresponding mold (right) must be oversized. Shrinkage offers the advantage of reducing the size of imperfections left by the mold.

Optical-component catalogs go on-line

The optics industry rests on the foundation of catalog components. Off-the-shelf mirrors, lenses, beamsplitters, filters, polarizers, and prisms are used in laser oscillators, focusing objectives, relay optics, and instrumentation such as spectrometers. Catalogs of standardized optical components are included in some optical-design codes, allowing the designer to craft a system that takes advantage of economical, readily available components. A variety of optical-component catalogs are available by mail from optics manufacturers (see below). But in the past year, catalog optics have gone electronic via the World Wide Web. Herewith a sampling:

At the Oriel Instruments (Stratford, CT) home page (http://www.oriel.com/WWW/adv.oriel.html), users will find a partial catalog with component specifications, technical notes, and US and Canadian prices. For those who prefer hard copy, the home page allows users to order a copy of the 1995 catalog.

The Melles-Griot (Irvine, CA) online catalog (http://www.mellesgriot.com) offers product listings, technical information, electronic contact information for support staff, and online literature requests. A OWhat?s NewO listing provides details about new products.

Casix (Fuzhou, China) offers full product specifications and extensive technical notes with detailed graphics at its home page (http://www.newsight.com/newsight/casix.htm). The page includes new product announcements, contact information, and a company profile.

At the New Focus (Santa Clara, CA) home page (http://www.newfocus.com), visitors can view drawings of catalog products, find out which conferences and tradeshows New Focus staff will be attending, and order free literature and application notes. The 112-page 1995/1996 catalog is currently available only in hard copy.

Catalogs by mail

In the offline world, many companies offer specialty catalogs that contain valuable technical information. In addition to its main catalog, CVI Laser Corp. (Albuquerque, NM; tel.: (505) 296-9541) offers a newly released polarization guidebook. The 64-page volume contains selection guides that help customers understand their needs and choose the correct components for their applications. The guidebook also introduces CVI optical mounts, heralding the company?s entry into that market.

Meadowlark Optics (Longmont, CO; tel.: (303) 776-4068) has released a 1996 polarization handbook that contains technical notes, application notes, and a summary of fundamental polarization theory. The catalog also includes a chart comparing conventional and novel methods of phase retardation, complete with product specifications and price comparisons.

Laser, video, and optical component supplier Edmund Scientific (Barrington, NJ; tel.: (609) 547-3488) recently released a new edition of its Video Imaging Primer, a technical reference that discusses video systems for industrial applications. The primer answers frequently asked questions, and the information included allows customers to select the right system components for their application.

Spindler & Hoyer (Milford, MA; tel.: (508) 478-6200) provides extensive technical and application notes in its 1995 catalog and plans to release the 1996 edition by the end of the year. The volume includes a discussion on DIN and ISO quality standards and how they relate to component specifications. Spindler & Hoyer also markets a ray trace code that includes an optics catalog to simplify the design process.

In its 1994/1995 catalog, Newport Corp. (Irvine, CA; tel.: (800) 222-6440) offers technical notes, applications notes, and a gradient lens kit. The company will release its 1996 edition in late spring.

Stock optics supplier Rolyn Optics (Covina, CA; tel.: (818) 915-5707) offers a 130-page catalog along with 24-hour delivery in many cases.

A well-crafted catalog can be critical to the success of an optics supplier. The formation of optical components supplier OptoSigma (Santa Ana, CA; tel: (714) 851-5881) was announced in July, and within the week a 152-page catalog was available. The volume includes specifications, tolerances, and prices on a range of laser-quality optics, polarization components, optical mounts, and micropositioning equipment.

Kristin Lewotsky

Custom optics manufacturer Bern Optics

(Easthampton, MA) turns stock components such

as a Melles-Griot rectangular cylindrical lens into

custom optics (the rounded, stepped cylindrical lens

at bottom center). Bern also supplies components to catalog houses.

david ryan photography