MICROSTRUCTURED OPTICS: Moving toward the nanoscale

HANS PETER HERZIG, IWAN MÄRKI, TORALF SCHARF, AND WATARU NAKAGAWA

Diffractive optical elements are components that rely on the physical phenomena of diffraction and interference to control the propagation of light.1, 2, 3 Such elements are usually macroscopically planar microstructures, consisting of features with dimensions from a couple of wavelengths to a few tens of microns and are designed by advanced numerical algorithms based on diffraction theory. They are fabricated by modern micromachining, including optical lithography, direct-laser and electron-beam writing, and reactive-ion etching.

In the past decade, diffractive optics has emerged as a powerful tool to realize various optical functions that have not previously been possible or feasible using conventional optical elements. In parallel, microlens technology has been developed based on the same fabrication technologies that enable efficient batch fabrication. Such elements, using either refractive or diffractive surfaces, are now found in applications ranging from laser-beam shaping in laser-based materials processing to optical interconnects in telecom applications.

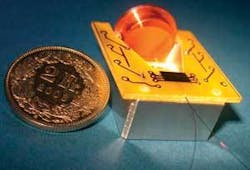

One of the major strengths of micro-optics compared to conventional optics lies in the fact that micro-optics allows integration of large, complex optical systems into much more compact form. In addition, emergence of replication techniques such as injection molding allow the low-cost mass-production of micro-optical elements. One example is a compact Fourier-transform spectrometer (see Fig. 1); the heart of this spectrometer is a tunable grating with variable depth (several hundred micrometers) realized by silicon micromachining.4

The progress in diffractive optics, or micro-optics in general, is closely related to the progress in microfabrication technology. In addition, powerful computers are now available to efficiently calculate complex optical structures based on Maxwell’s equations. As a result, researchers working in diffraction optics are now increasingly working with structures containing subwavelength-size features.

Resonant-grating filters

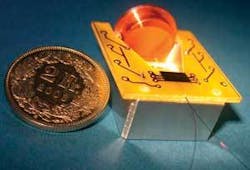

By combining microstructures with thin films, it is possible to create elements that exhibit very strong changes in reflection and transmission as a function of wavelength, angle of incidence, and polarization. One such element is the resonant-grating filter (RGF).5 A grating is used to couple incident light into the leaky mode of a waveguide layer. The grating pitch, depth, and layer thicknesses are chosen to provide high reflectivity at the resonance wavelength and low reflectivity for a reasonable band on either side. The advantage of such a design is that only three layers are used to provide a narrowband reflectivity of nearly 100%, making this lightweight, low-profile structure interesting for mounting on an optical MEMS (microelectromechanical systems) platform (see Fig. 2).6 The device can be used as a switch or wavelength filter in telecom applications. Similar structures have interesting applications as security features on bank notes and credit cards. Particular color effects can be achieved depending on orientation of the sample and diffractive structures similar to those of butterflies, beetles, or spiders have been realized.

Photonic crystals

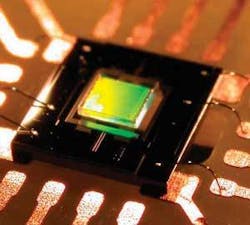

Photonic crystals are natural descendants of diffractive optics. Photonic crystals (PCs) are periodic structures that provide exciting ways to control light, as well as permit further miniaturization of optical devices (see, for example, www.laserfocusworld.com/articles/274717).7 One of the most promising realizations of PCs is the 2-D planar PC membrane, which confines light by means of a photonic bandgap in-plane and by index-guiding in the vertical direction. These structures provide the possibility of creating miniaturized photonic components such as straight or bent waveguides, wavelength filters, or microcavities.8 The ability to control or to tune the behavior of such structures opens up greater flexibility and new possibilities for integrated optical circuits. In particular, PC resonant cavities are of great interest in the process of realizing active tunable photonic components because they exhibit high spectral resolution and confine light in a very small volume.

Different tuning mechanisms (mechanical and optical) have been studied theoretically and experimentally.9, 10 Mechanically, a perturbation can be achieved using the tip of an atomic-force microscope (AFM; see Fig. 3). In this case, the PC structure is in a free-standing silicon membrane, which allows access to the microcavity region. Based on a simplified resonant-cavity structure, 3-D simulations have been performed on a silicon tip situated above the cavity perturbing the optical field by modulating the distance between the tip and the surface of the membrane. If the tip is inserted into one of the holes that form the cavity mirror, the resonance frequency shifts by greater than 10 nm. Thus, tuning of the cavity becomes possible and could be the basis of a stand-alone MEMS technique for creating a chip-based on/off switch or tunable filter.

The confined field within the microcavity can also be perturbed optically by focusing a laser with a shorter wavelength onto the center of the microcavity. A laser-induced wavelength shift of 5 nm has been achieved. By modulating the probing laser, the output signal can be varied. The modulation depth depends on the quality factor Q of the microcavity and the induced resonance wavelength shift. A modulation frequency of 100 kHz has been observed-this being the maximum modulation rate of the probing laser, not the cavity. In recent experiments, we achieved higher frequency in the megahertz range, still limited by the maximum modulation rate of the probing light. This form of perturbation could form the basis of a high-speed all-optical modulator.

Nanoparticles

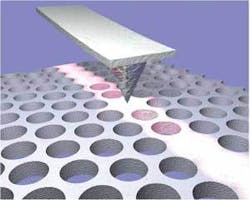

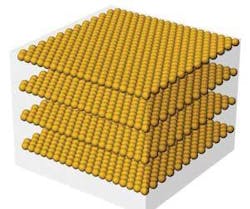

Complex artificial photonic materials can be realized by exploiting the self-organization of materials with different optical properties on a nanoscopic length scale. Using those materials, different concepts can be envisioned to realize optical elements that are based on the engineered control of the dispersion relation in such media.

The inclusion of plasmonic material seems to be a preferable approach for obtaining strong resonances in the material dispersion over a narrow spectral domain. The most elegant way would be to incorporate metallic nanoparticles into macromolecules and search for self-organization of such molecules in liquid-crystalline phases (see Fig. 4). Plasmons play a key role in linking electronics, optics, nanoscience, and information technology by providing new classes of photonic and electronic devices that control and manipulate light at the nanometer scale, as well as generating, transporting, and detecting digital information for applications in medical diagnostics, chemical sensing, homeland security, environmental science, high-speed data communication, and computing components.11

null

Seeing at the nanoscale

Fabrication at the nanoscale also requires seeing at the nanoscale. Scanning-probe optical microscopy is a powerful technique that allows the 3-D detection of optical fields displaying subwavelength-scale features down to the nanoscale. This class of instrument is the natural evolution of scanning near-field optical microscopy; in this case, one can obtain nanoscale resolution by detecting the optical near-field of a sample.

Measuring the electromagnetic-field distribution inside the structure of a photonic device such as a photonic-crystal waveguide to a nanoscale resolution is important for understanding the fundamental behavior of the device, as well as for optimizing its structure. This information is invisible with the use of a conventional lens system. Subwavelength-scale variations in structure and evanescent waves can be observed by scanning near-field microscopy.12 Of particular interest is amplitude and phase measurement using heterodyne techniques to get full information about the light distribution.

REFERENCES

1. H.P. Herzig, ed., Micro-Optics: Elements, Systems, and Applications (Taylor & Francis, London, 1997).

2. J. Turunen, F. Wyrowski, eds., Diffractive Optics for Industrial and Commercial Applications (Akademie Verlag, Berlin, 1997).

3. S. Sinzinger and J. Jahns, Microoptics (Wiley-VCH, Weinheim, 1999).

4. O. Manzardo et al., Optics Lett. 29(13) 1437 (2004).

5. S. Tibuleac and R. Magnusson, J. Opt. Soc. Am. A 14, 1617 (1997).

6. T. Overstolz et al., Proc. SPIE 5455, 240 (2004).

7. E. Yablonovitch, J. Opt. Soc. Am. B. 10, 283, (1993).

8. B. S. Song et al., Nature Materials 4(3), 207 (2005).

9. I. Märki et al., Optics Express 14(7) 2969 (2006).

10. Iwan Märki et al., Optics Lett. 31(4), 513 (2006).

11. EOS Topical Meeting on Molecular Plasmonic Devices, April 27-29, 2006, Engelberg, Switzerland (European Optical Society, 2006).

12. P. Tortora et al., Optics Lett. 30(21), 2885 (2005).

HANS PETER HERZIG is a full professor, IWAN MÄRKI is a postdoctoral researcher, TORALF SCHARF is a group leader and lecturer, and WATARU NAKAGAWA is a group leader at the Institute of Microtechnology, University of Neuchâtel, A.-L. Breguet 2, 2000 Neuchâtel, Switzerland; e-mail: [email protected].