VISION-CORRECTING OPTICS: Thin spectacles tackle presbyopia and astigmatism

While post-processing algorithms can extend the depth of focus in digital-imaging applications, they cannot be implemented in real time for human ophthalmic applications. All-optical methods that extend the depth of focus include apodizing the lens aperture or using diffractive optical elements; however, these methods reduce the throughput of the optical system and suffer from diffraction and chromatic effects.

That was before researchers at Xceed Imaging (Petach-Tikva, Israel) together with Bar Ilan University (Ramat Gan, Israel) adapted an all-optical solution used in digital imaging to ophthalmic applications and developed extended-depth-of-focus (EDOF) thin spectacles.1 The spectacles are coated with an approximately 1-µm-thick phase-only optical element that improves vision in presbyopic and even astigmatic eyes with unaffected throughput and without chromatic or diffractive effects.

The optical element is a thin-film replicated polymer coating constructed out of transparent areas and binary phase circles that modulates the entrance pupil of the imaging lens. The binary phase circles are repeatedly distributed across the aperture of the spectacle such that the extended depth of focus generates correction for the accommodative insufficiency across the full field of view. For each one of the circles, the position of the binary phase transitions and features of the coating structure are computed using an iterative algorithm that provides maximal contrast of the optical transfer function under a certain set of out-of-focus conditions typical to presbyopic or astigmatic eyes. That is, the optical structures vary as a function of the ophthalmic deficiency of the patient.

Numerical simulations using Code V software optimize the surface treatment for the thin spectacles and extract the required function of the element under the above-mentioned optimization conditions while taking into account full modeling of the eye. After extracting the optimal function of the phase element, the glass surface can be coated with a thin layer of the proper photosensitive polymer and the required phase function is recorded on this surface. The recording can also be done via stamping technology—an approach better suited to mass production. In this case the surface of the glass is coated with a polymer layer and the structure is stamped into it by applying heat and pressure. Because the fabrication process is easy to implement, the cost of the thin spectacles is minimal.

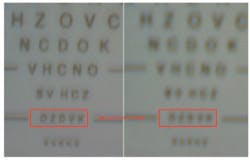

The thin spectacles essentially have the effect of expanding the in-focus area to the wearer. For presbyopia-the most common ophthalmic deficiency in which focusing of near objects is difficult because of weakening muscles that cannot adequately focus the lens of the eye-reading glasses or bifocals can restore vision, but over a limited field of view and distance range. Experiments determined that the thin spectacles provided an EDOF improvement in vision equivalent to 3.00 D (diopters) for pupil diameters from 2 to 4 mm (representing a range of illumination conditions). That is, the spectacles provide an EDOF over the range of 0.00 to 3.00 D, correcting vision for individuals that require eyeglass prescriptions in that range (see figure). If the coating is added to eyeglasses with a value of 2.00 D, those coated spectacles will produce an EDOF from 2.00 to 5.00 D, further extending the capabilities of prescription optics.

For astigmatism, in which the lens of the eye has different focal lengths in different axes, no good optical solutions are currently available. Testing of thin spectacles on human subjects revealed vision improvement of 2.00 D for astigmatic eyes.

Researcher Zeev Zalevsky says that besides the scientific breakthrough and interest, the proposed technology can serve mankind by increasing the performance throughput of available ophthalmic solutions. “This technology is currently being adapted for contact lenses and interocular lenses as well; first prototypes will be available in the upcoming months,” says Zalevsky.

REFERENCE

1. Z. Zalevsky et al., Optics Express15(17) 10790 (Aug. 20, 2007).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.