TUNABLE LASERS: Optimized SOA ups power in DBR tunable laser

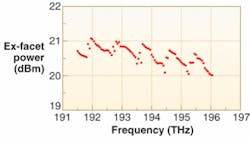

By optimizing the monolithically integrated semiconductor optical amplifier (SOA) in a tunable distributed-Bragg-reflector (DBR) laser, researchers at Bookham (Northamptonshire, England) have achieved a record output power level of more than 20 dBm ex-facet over the full telecom C-band (from 1530 to 1565 nm).1

In the past, widely tunable lasers have not produced quite as much optical power as their fixed-wavelength, distributed-feedback (DFB) counterparts; the difference being anything from 1 to 5 dB. The Bookham result shows that DBR lasers can match the 20 dBm typical of a high-power DFB across the full tuning range. These devices can therefore address applications that a high-power DFB might previously have been used for, but with the added benefit of full-band tuning. The 20 dBm output power is-to the knowledge of the Bookham engineers-an industry record for a DBR laser.

The laser is a digital supermode distributed-Bragg-reflector laser with an integrated semiconductor optical amplifier (DSDBR-SOA). The SOA does not form part of the actual laser cavity, but is monolithically integrated within the same chip. These DSDBR-SOA devices are fabricated using well-established indium phosphide (InP) processing techniques, based around a surface-ridge laser process. A key step in this process is an e-beam grating process for the realization of the front and rear grating reflectors, which are key to the device’s wide tuning range. The front grating is continuously chirped (the grating pitch varies along its length) and to it a number of small tuning contacts are applied. The rear grating is a phase grating which produces a comb of equally spaced reflection peaks and has a single tuning contact.

The front grating response can be shaped by applying an electric current selectively to one or more of the front contacts. This current causes a local change in the refractive index. This shaping can bring the front reflection peak into alignment with one of a series of the rear grating reflection peaks. The alignment determines the wavelength of highest optical feedback into the laser cavity and hence fixes the lasing wavelength. By tuning front and rear gratings together, the lasing wavelength of the cavity can be tuned over a range on the order of 7 nm, which is the typical spacing of the rear-comb peaks. This subset of the total tuning range is known as a supermode. By selecting each rear peak in the rear comb in turn, and reshaping the front reflector accordingly, it is possible to obtain a quasi-continuous wavelength selection over the full range spanned by the rear reflection comb-typically 45 nm or more. This one-at-a-time selection of supermodes gives the Bookham device its name, “digital-supermode” DBR laser.

The 20 dBm output power was achieved using an SOA with a 450 × 4.5 µm gain section (see figure). Although the increased facet width from 3.2 µm in earlier designs to 4.5 µm in this design changes the far-field pattern and causes a slight reduction in fiber coupling efficiency, overall higher output power is achieved. In addition, side-mode suppression ratio over the entire C-band is at least 40 dB.

“The monolithic aspect of the Bookham DS-DBR laser is important: it enables scalable and low-cost manufacture, especially when compared to external-cavity tunable lasers, which require multiple optical elements and are therefore not scalable from the wafer level,” says Andrew Ward senior scientist. “This paper demonstrates a significant step forward for improving the efficiency and performance of our laser products. We are now working on integrating these improvements into our existing portfolio of tunable laser products.”

REFERENCE

1. L. Ponnampalam, A.J. Ward, and D.J. Robbins, Electronics Lett. 43(16) 872 (Aug. 2, 2007).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.