With mobile-display sales surpassing one billion units in 2006 (see Optoelectronics Report, Oct. 15, 2007; www.laserfocusworld.com/articles/309264), it isn’t surprising that innovations such as mobile projection will continue to attract technologists as users thirst for a large-screen experience from their miniature mobile devices (see Fig. 1).1 While Mitsubishi, Samsung, and LG Electronics already have stand-alone “pocket” projector products that use Digital Light Processing (DLP) technology from Texas Instruments (Dallas, TX), Chris Chinnock, president of market-analysis firm Insight Media (Norwalk, CT), thinks that 2009 will be a significant year for the release of miniature projectors embedded into mobile devices such as cell phones. Today, at least four major manufacturers are vying for this mobile-projection market: Microvision (Redmond, WA), Texas Instruments, Explay (Herzliya, Israel), and Light Blue Optics (LBO; Cambridge, England). Konica-Minolta and Canon also have projection technologies in the works.

Although projection technologies fall into several categories, including scanning systems that use one or more mirrors to scan a laser beam to form a full image, and imaging systems that translate an image from a microdisplay onto the viewing surface, each manufacturer has its own unique technology platform and aggressive time-to-market forecast.

Scanning systems

Microvision calls its PicoP the “world’s thinnest and lowest power projector” thanks to a biaxial microelectromechanical-system (MEMS)-based light-scanning platform for display and image capture. Unlike projection systems that use a MEMS array with one mirror for each and every pixel of an image, PicoP uses just one scanning mirror to “paint” the image, pixel by pixel, on the screen, without the need for a bulky projection lens. Images are created using red, green, and blue laser diodes. Microvision’s design manages every milliwatt of power by adjusting the light intensity of each laser source as and when it is needed for each pixel, significantly reducing thermal issues on other components inside the mobile device. By contrast, some other systems require the light source to be on continuously, regardless of the content being displayed.

Mobile products based on the PicoP engine target a battery life of two hours or more and offer a brightness of more than 10 lumens. And rather than offering the standard QVGA resolution of 320 × 240 pixels, PicoP’s engine is currently at WVGA resolution or 848 × 480 pixels-near DVD quality and sufficient to support devices such as laptops, Apple’s iPhone, and Internet gaming consoles.

In July, Microvision signed an agreement with Motorola to develop PicoP projector display solutions for mobile applications. Production readiness for an accessory product using the PicoP engine is targeted for the second half of 2008. Microvision anticipates that the PicoP-embedded projector module will be production-ready during 2009.DLP technology

Another pico-projector using a MEMS-based approach is Texas Instruments’ DLP device (see Fig. 2). The DLP chip contains an array of MEMS mirrors that-when coordinated with a digital video or graphic signal, an RGB sequential color light source, and projection optics-creates an image that is projected onto a screen or other surface (see www.laserfocusworld.com/articles/277186). The individual MEMS mirrors act as switches turning each pixel on or off; no scanning is used in this projection technology. Because each mirror represents a discrete pixel, it is possible to obtain higher image quality than some other technologies.

Digital Light Processing-based pico-projectors are extremely thin, compact, low-energy-consumption solutions for mobile projection, without adverse artifacts such as speckle. And because the DLP solution has the option of being laser or light-emitting-diode (LED)-based, manufacturers have the option of not using safety labels or having safety concerns. With a known track record in pocket projection systems, the high contrast ratio, fast switching speeds, high optical efficiency, and wide color gamut of DLP-based technology should translate easily to mobile platforms. Recently, Foxconn (Taipei County, Taiwan), Sypro Optics (Jena, Germany), and Young Optics (Hsinchu, Taiwan) announced that they would be designing and building projection engines based on Texas Instruments’ DLP technology for embedded and stand-alone mobile applications.Imaging systems

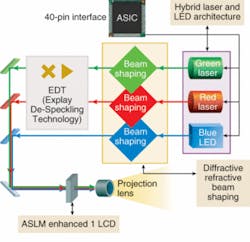

Explay’s nanoprojector engine with projection-screen capability from 7 to 30 in. incorporates a variety of innovations. A mobile-device video signal is recreated by a hybrid laser diode and LED source in a patented configuration and passed to beam-shaping optics and then through a despeckling device (see Fig. 3). The signal is then routed through a microdisplay that incorporates microlens-array technology to enhance light-modulator efficiency from 25% to 60%. Even though the final image is projected using a lens, the image is always in focus.

Explay’s hybrid light-source architecture can utilize readily available and lower-cost green diode-pumped solid-state (DPSS) lasers, red laser arrays, and blue light-emitting diodes (approximately 20 times cheaper than blue lasers) because of the minimal requirement of on/off modulation at the frame rate. The Gaussian beams go through refractive and diffractive beam shaping that take the nonuniform Gaussian distribution of the light and reshape it to uniform rectangular beams the size of the microdisplay. These beams pass through Explay’s De-speckling Device (EDT), which destroys the temporal coherence of the light. Folding and combining optics then channel the light to the microdisplay and through projection optics to the screen. Explay offers an eye-safe Class 1 product compared to some others that are Class 2 and even Class 3 devices.

In October, Explay and Iljin Display of Korea signed a multi-million dollar strategic agreement to accelerate the integration of personal projectors into various consumer electronics devices. Iljin Display manufactures microdisplays based on its own proprietary 1-LCD technology. Explay also signed a collaboration agreement with Luminetix (Memphis, TN), a medical imaging company, to develop and commercialize an ultrasmall mobile projector that will be a key component in the future development of Luminetix’s VeinViewer product.

The first Explay “oio” nanoprojector was publicly unveiled at SID 2007 in Long Beach in May; commercial availability is targeted for the second half of 2008.

Holographic laser projection

Light Blue Optics uses a novel approach to projection in its miniature light engines: holographic laser projection. The term “holographic” refers not to the projected image, but to the method of projection. Proprietary algorithms convert the desired two-dimensional (2-D) image into diffraction patterns (or holograms) that are displayed on a phase-modulating liquid-crystal-on-silicon (LCOS) microdisplay. When these holograms are illuminated by coherent red, green, and blue laser light, the desired 2-D image is formed by the physical process of diffraction.Unlike conventional imaging projection systems that block light to create dark areas, LBO’s holographic laser projection technology steers the light to exactly where it is needed. In addition, LBO’s technology allows the lasers to be modulated at frequencies several orders of magnitude less than scanning systems, providing substantial power savings. There is no need for a focus control as images remain in focus at all distances from the projector; images can also be projected onto curved or angled surfaces without distortion. Furthermore, the throw angle (the angle at which the image leaves the projector aperture) can be greater than 100°, creating large images at extremely close proximity to the projector aperture while maintaining an acceptable laser safety classification.

Because the hologram pattern is not a 1:1 representation of the desired image, the system is highly tolerant of microdisplay pixel failure-essential in safety-critical applications such as automotive and avionic head-up displays. The holographic method can combine a number of built-in speckle-reduction techniques, as demonstrated at SID 2007. The LBO system also has no moving parts, no projection lens, and-because the physical process of diffraction becomes increasingly effective at smaller feature sizes-is well suited to miniaturization and the production of light engines as small as 5 cc (see Fig. 4).

Light Blue Optics recently raised $26 million to accelerate the product development of its laser-based projection systems, and plans to launch its first products in the fourth quarter of 2008.

REFERENCE

1. F. Moizio, R. Hannigan, G. Manor, C. Chinnock, and E. Buckley, Proc.of SID Mobile Displays 2007, Session V: Projection Technology for Mobile Devices, San Diego, CA (Oct. 3, 2007).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.