Scientists continue to find inspiration in biological plants and animals as they work toward developing practical photonic systems. Biomimetics is again playing a role for researchers at the University of Florida (Gainesville, FL) and Portland State University (Portland, OR), who have developed antireflection coatings that mimic antireflective moth eyes.1

Existing antireflection coatings, such as quarter-wavelength multilayer films and nanoporous coatings, are expensive and difficult to manufacture. And although the natural sub-300 nm arrays of non-close-packed nipples that reduce reflections from the compound eyes of moths have been studied as antireflection coatings, current lithography-based fabrication methods are also expensive and limited by either low resolution or small sample size. In addition, self-assembly techniques are generally not viable for industrial-scale fabrication, and are usually limited to the creation of close-packed structures.

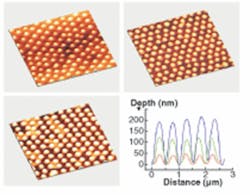

Despite these apparent impediments, the researchers developed a spin-coating technology that combines the simplicity and cost-effectiveness of self-assembly with the scalability of top-down microfabrication techniques to create large-area moth-eye antireflection coatings with adjustable reflectivity. The process involves the shear alignment of spherical colloidal silica crystals suspended in a polymer matrix. A reactive-ion etch removes the surface polymer, leaving the crystals exposed in a polymer base over a silicon substrate. The long-range-periodic surface protrusions of the shear-aligned crystals are easily transferred to a polydimethylsiloxane (PDMS) mold, which can be used to create nipple arrays that simulate the surface of a moth eye. The PDMS mold allows the creation of these arrays over a broad area, on both planar and curved substrates.

Experiment matches theory

The shape and depth of the individual nipples in the array can be easily adjusted by controlling the reactive-ion-etching process. Measurements of reflectivity using an Ocean Optics (Dunedin, FL) fiber-optic UV-visible near-IR spectrometer with a reflection probe show that reflectivity varies directly as a function of reactive-ion etch time. Furthermore, the specular reflection of these nipple arrays matches the theoretical predictions obtained using a thin-film multilayer model.

“The spin-coating-enabled templating technique is scalable and manufacturable,” says Peng Jiang, assistant professor of Chemical Engineering at the University of Florida. “We are currently exploring the technological applications of replicated moth-eye antireflection coatings in flat-panel displays, optical elements, and solar-cell collectors. Our group is also working on developing new self-assembly-based nanomanufacturing techniques for biomimetic multifunctional coatings. For instance, an optical coating is being developed to mimic the unique functionalities of antireflective moth eyes and superhydrophobic cicada wings for self-cleaning antireflection coatings. Furthermore, we are exploiting templated subwavelength-structured antireflection coatings for improving the conversion efficiencies of crystalline silicon solar cells.”

REFERENCE

1. N.C. Linn et al., Applied Phys. Lett.91, 101108 (2007).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.