Designing safety into optical networks

YVES DELISLE, GENG PENG, AND

BRIAN LAVALL

null

In just a few short years, the telecom industry has achieved huge leaps in information-carrying capacity by deploying high-speed optical transmission. Bit rates have quickly increased from 2.5 to 10 Gbit/s today and will reach at least 40 Gbit/s in the future. The number of copropagating channels in dense wavelength-division multiplexing (DWDM) systems also has been steadily increasing. The end result is vastly improved optical-fiber bandwidth utilization. To support the existing fixed span losses at these higher line rates, the use of distributed Raman amplification combined with high-power erbium-doped fiber amplifiers (EDFAs) will increase the amount of optical power present in the optical-fiber plant.

Capacity increases via DWDM also translate into total optical-power increases proportional to the number of copropagating channels. Hence, safety engineering must play a critical role in system design and associated engineering practices.

Hazardous light and maximum permissible exposure (MPE)

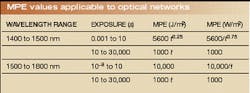

Damage to human tissues from exposure to different energy sources is proportional to the exposure duration and power intensity. The susceptibility of human tissues to electromagnetic fields also varies according to wavelength. The International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) propose a maximum permissible exposure (MPE) value that defines a limit of exposure below known hazard levels that are based primarily upon empirical studies (see table, p. 163).1, 2 The IEC and ANSI also define a skin MPE that is slightly different from the ocular MPE above 1500 nm. Since ocular injuries are inherently more severe than skin burns, however, the ocular MPE remains the key criteria to distinguish between hazardous and nonhazardous light in optical networks.

The MPE varies with wavelength, yielding values that are typically lower in the 1400-nm range than in the 1500-nm range, except for long exposures (see Fig. 1). These MPE values are expressed in terms of the energy or power passing through a circular aperture of a given diameter d0 normalized to the aperture area. The IEC specifies the limiting aperture to a diameter d0 of 1 mm for exposure durations less than or equal to 3 s, or 3.5 mm otherwise.

Hazard beam assessment

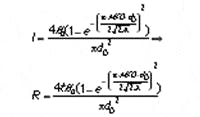

To ensure that light emitted from an open connector or broken fiber does not exceed the MPE limits, the source properties (wavelength and power) must be considered, as well as the fiber properties (mode-field diameter and its wavelength dependency), and exposure properties (distance, duration, and position relative to the source). This is achieved using the following equation, derived from Gaussian optics, that evaluates irradiance or radiant exposure in worst-case direct viewing conditions:3-6

null

where I = irradiance (W/m2), R = radiant exposure (J/m2), d0 = diameter of limiting aperture (m), z = distance from the fiber output in the beam axis (m), f0 = power at the fiber end (W), t = exposure duration (s), l = wavelength in air (æm), and MFD = fiber mode field diameter (æm).

For larger MFD values, the amount of power coupled into the limiting aperture is more important since these fibers yield less divergent beams. Among the commonly deployed single-mode fibers, non-dispersion-shifted fiber (NDSF) has the largest MFD, making it the benchmark for worst-case values determination (see Fig. 2). The highest coupling efficiency is obtained at the smallest wavelength (about 7.7% in this case). When MFD is held constant and equal to 11.2 æm (maximum MFD at 1550 nm), the error becomes quite significant in the region of 1400 nm.

In cases where multiple wavelengths are present in a given fiber, they may be treated as if all power is concentrated within the smallest wavelength. Although this slightly overestimates the power coupled into the limiting aperture, it is indeed acceptable since the coupling efficiency is almost constant.

Materials damage

Any component present in the high-power optical beam path needs to be designed according to the level of power to which it is going to be subjected. At the system level, there are several failure modes that may be easily avoided if the high-power light traveling within the fiber is physically contained. This implies no significant loss points or reflection points along the entire portion of a given span where optical power is high. In the fiber plant, loss points and reflection points can arise from connectors, splices, and micro/macro fiber bends. The potential hazards that can be encountered with high optical power in a typical optical network include fiber fuse, coating fire, and connectors or splices damage.

Fiber fuse. In optical fibers carrying high levels of optical power, a loss, or more likely a break, may initiate a phenomenon that will destroy the fiber and is also capable of damaging the optical components within the system as well. This phenomenon is known as a "fiber fuse," which propagates backward toward the light source during its life.7-9

Coating fire. When bends are applied to fibers, trapped light can hit the fiber core-cladding contact region at an angle sufficient enough to produce radiant losses. Micro bends are small bends or deformities in fiber that will arise from pinched fibers, mechanical stress, kinks, and twisted fibers. Macro bends are larger and originate from minimal bend-radius violations. If sufficient power is present within a fiber, escaping light can create heat concentrations that result in coating fires and/or fiber fuses. Although the fiber can still retain its transmission properties after a coating fire, it will become very fragile.

Connectors or splice damage.Optical connectors are a likely source of insertion loss and reflection. A connector can be permanently damaged if contaminated before and/or during installation. Experiments and tests conducted in our own facilities show that light-absorbing contaminants can permanently damage fiber ends even at power levels of less than 100 mW.10 Thus, fiber plants must be properly engineered to minimize the number of optical connectors and to facilitate their cleaning and inspection.

Safety mechanisms

All fiber and connectors that will be subjected to high power must be protected by safety mechanisms that detect optical-path discontinuity and subsequently reduce power to safe levels. The definition of "high power" varies with respect to the amount of exposure considered possible in a given application. In the IEC OFCS standard, the differentiation is based on types of location access-unrestricted, restricted, and controlled. The limit at which optical power is viewed as high is often set at 50 W. Different names are also used to identify various available safety mechanisms such as APR (automatic power reduction), ALS (automatic laser shutdown), and APSD (automatic power shutdown). Here, APR is used in lieu of ALS and APSD where appropriate.

Reaction time. Automatic power-reduction reaction time is the time it takes the output power to reach the lower level and is comprised of the detection, decision, and action times. The APR reaction time should be specified to prevent any exposures in excess of MPE limits upon a fiber cut or open connection. Determination of the maximum acceptable APR reaction time is based on the condition of possible exposures after a fiber cut or connector accidentally opened. Typically, given the small APR reaction time, the actual amount of time available to physically bring the open end of a fiber with high power close enough to the eye is quite small. Thus, for practical reasons, the worst-case possible exposure to derive APR reaction time is typically at a distance of 10 cm without viewing aids. To take into account the largest possible irradiance or radiant exposure, it is convenient to use a limiting aperture of 1 mm (smallest diameter for any exposure duration in IEC and ANSI standards). Expression of the radiant exposure in the previously mentioned equation and the MPE limits specified in the table may be used to derive a simple expression for the maximum APR reaction time.

Power requirements. The APR power must be low enough to prevent long-term exposures in excess of the MPE limits (greater than 10 s). Since we are concerned with much longer durations, the possibility of exposure at shorter distance, or while using viewing aids, must be considered. Typically, a viewing aid with a certain angular magnification factor (M) is a device that allows the user to get a clear picture of an object more closely than allowable by the eye by simply placing the object at the focal distance of the device. The focal distance (f) of the device, or equivalently, the distance of the fiber end to the ey, is related to the angular magnification M by f = 250 mm/M (where the 250-mm value is the punctum proximum of the human eye). Therefore, if losses are neglected, using viewing aids with a large magnification factor is equivalent to staring at the fiber end at a zero distance. At a null distance and for long exposure, the MPE limit of 1000 W/m2 (over a circular limiting aperture of 3.5 mm) is reached at a power of 9.6 mW, which is a highly desirable requirement.

Architectural and reliability requirements. The APR must be a very efficient safety mechanism and as such must trigger each time a fault is detected in the optical path. Thus, APR must be highly sensitive in nature. However, by nature APR mechanisms affect service, which means that the number of false triggers must be minimal. To mitigate these opposing goals, optical-path continuity assessment may be based on independent measures involving independent decision-making mechanisms, such as multipoint redundant decision. To improve the safety mechanism's availability and effectiveness, the decision should be taken as close as possible to the measurement points themselves.

As the optical networking industry strives toward increasingly cost-effective solutions, the levels of optical power launched into the fiber plant will increase dramatically as well. Safety engineering must become a well-understood discipline that is applied by both the equipment vendors and the service providers alike. In today's higher-power optical-fiber communication networks, inherent hazards can be eliminated via proper equipment design and applied operational practices.

REFERENCES- IEC 60825-1, "Safety of Laser products-Part 1: Equipment classification, requirements and user's guide," Edition 1.1 (1998).

- ANSI Z136.1, "American National Standard for Safe Use of Lasers" (2000).

- IEC 60825-2, "Safety of Laser products-Part 2: Safety of optical fibre communication systems," second edition (2000).

- ANSI Z136.2, "American National Standard for Safe Use of Optical Fiber Communication Systems Utilizing Laser Diode and LED Sources" (1997).

- E. G. Neumann, "Single-Mode Fibers Fundamentals," Springer-Verlag (1988).

- P. Das, "Lasers and Optical Engineering," Springer-Verlag (1990).

- R. M. Percival, E. S. R. Sikora, and R. Wyatt, Electron. Lett. 36(5) (March 2000).

- D. D. Davis, S. C. Mettler, and D. J. DiGiovanni, Proc. SPIE 2714 (1996).

- D. D. Davis, S. C. Mettler, and D. J. DiGiovanni, Proc. SPIE 2966 (1996).

- M. E. De Rosa et al., OFC 2001.

null

null

YVES DELISLE, GENG PENG, and BRIAN LAVALLÉE are members of the optical line systems engineering team of Nortel Networks in Montr?al, Que., Canada; e-mail [email protected].