Laser displays move from the amphitheater toward the living room

At the dawn of electrical technology, electric illumination by arc lamps was suitable only for high intensity outdoor applications. Edison "subdivided the electric light" by inventing the light bulb and making electric lighting available for small-scale indoor uses. Laser light-show displays are following a similar route. Until recently, full-color displays have required expensive and high-power argon-ion lasers and were economical only for large audiences. But with the development of all-solid-state three-color laser display units, price and power requirements have dropped dramatically. While such displays can't yet be shrunk down to the requirements of a home TV, such applications are on the horizon.

The displays

Displays can be based on a variety of different lasers, depending on the particular application. Until the recent advent of all-solid-state white-light lasers, the most capable full-color displays relied on mixed-gas argon/krypton ion lasers that produced up to eight frequencies of laser light. These are high-power devices, needing input power of 100 kW or more at 220 or 440 V and requiring water cooling. Hence, such full-color displays have been limited to the largest scale applications, such as light shows for audiences of a thousand or more, and large-screen projection TV and cinema, again for large audiences.

At a medium power level, frequency-doubled Nd:YAG lasers can provide dramatic beam effects, but since these lasers are pulsed and produce wider beams, they are not usable for projecting complex graphics. For single-color, small-scale displays, economical He-Ne lasers are used and can also be combined with medium-power air-cooled argon-ion lasers producing blue and green lines for somewhat smaller full-color displays.

A pair of small scanning mirrors, each typically 3 x 5 mm, directs the laser beams. One mirror directs the vertical coordinate; the other directs the horizontal coordinate. Closed-loop galvanometer scanners use position-sensing feedback to correct for accurate positions.

To eliminate connecting lines during a display, to modulate the intensity of the laser light, and to select colors in a full-color display, a modulator or "blanker" is required. In simple displays, the blanker can be an electromechanical device, just cutting off the laser light when needed. For anything more sophisticated, acoustic-optical modulators (AOM) are used.

Acousto-optic modulator cells can be made to act as tunable frequency filters that allow only a single frequency to pass. Such polychromatic AOMs (PCAOMs) can be used to control the color of a full-color laser display. White light from the laser—a mixture of three or more pure frequencies—is input to the PCAOM, which can direct the desired frequency to the scanner and the rest of the beam to a waste dump. By using several independent channels, simultaneous diffraction patterns can be set up to select for a mix of individual frequencies, thus creating any mixed color within a broad range. With argon/krypton lasers as many as eight channels are used, one for each primary laser line emitted.

Because full-color laser displays can modulate each pixel independently, they can project TV signals or digital cinema on very large screens with a brightness and color intensity otherwise impossible to achieve. Other typical applications are light shows at events, and planetarium special effects (see photo at top of this page).

In some laser displays spectacular effects are created by scattering the laser light off particles in the atmosphere, rather than reflecting it off a screen. Such atmospheric effects require some sort of fog to provide the scattering. Usually the best results occur when the laser beam is projected toward the audience. With skilled design, real three-dimensional effects can be obtained by scanning the beam across a cloud of fog. Three-D effects can also be obtained by using polarized laser light and polarized glasses.

The shift to solid state

All-solid-state full-color laser display systems are beginning to replace the older and far more expensive ion lasers. The first of these solid-state display lasers is the Schneider Showlaser, developed by Jenoptik Laser (Jena, Germany).1 The Showlaser won the 2001 Fenning Award for Technical Achievement from the International Laser Display Association (Bradenton, FL).

The Jenoptik system is based on a diode-pumped Nd:YVO4 oscillator, which provides 7-ps pulses at a repetition rate of 80 MHz—a rate too high to be perceived by the eye, even at a fast scan rate. The short pulse length cuts down on the traditional laser "speckle" patterns. In addition, the short pulses produce a high peak power of 80 kW, making possible efficient nonlinear frequency generation for production of the other wavelengths.

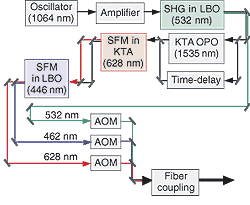

The infrared (IR) output of 4.5 W at 1064 nm is amplified by a diode-pumped laser amplifier and fed through a second harmonic generator to produce green at 532 nm. Nonconverted IR power is fed into an optical parametric oscillator (OPO) to produce a 1535-nm output.

The OPO output is then fed to a KTA (potassium titanyl arsenate) crystal for sum-frequency generation—the OPO signal is mixed with the unconverted 1064-nm laser output to produce red 629-nm photons. Mixing this red light with the OPO output in a lithium borate crystal produces blue light at 446 nm (see figure). Despite the relative complexity of these transformations, the total red green blue output of 18 W is 45% of the total amplifier output—enough to illuminate a screen tens of meters in area. Total input power is less than 3 kW, only a few percent of the requirements of ion lasers with similar output power. Reliability is also high, with a mean lifetime of 10,000 hours or about five years.Toward laser TV

Solid-state laser projection systems can not only provide images that are far brighter than other TV projection techniques, they can generate better color as well. Using the three frequencies that the Showlaser generates, about 90% of the colors perceptible to the human eye can be produced, more than double the range available to the conventional three-color cathode ray tube used in TVs. But with a 3-kW input power requirement, the show laser is hardly suitable for home TV. Here the output power must be in the area of 0.5 to 1 W per color, or about one-tenth of the power of the Showlaser, even for a large projection screen in the home.

Scaling power consumption back by a factor of ten is not trivial. To maintain the efficiency of the nonlinear conversion, peak power levels must be maintained. With a smaller average power output, this can only be done by decreasing pulse length, which is difficult for with the Nd:YVO4 laser medium. Both Jenoptik and other firms, however, are actively working on the various challenges that need to be overcome for a practical home laser projection system, and products are probably not more than a few years away.

For more information on the Schneider Showlaser, see www.whitelightlaser.com

About the Author

Eric J. Lerner

Contributing Editor, Laser Focus World

Eric J. Lerner is a contributing editor for Laser Focus World.