Excimers push machining limits for resolution, precision, and efficiency

Excimer lasers emitting at 351, 308, 248 and 193 nm are well-established industrial tools both in microlithography and high-precision laser material processing. Because of their unique physical properties that provide an essential advantage in both of these fields of application, fluorine (F2) laser sources play a key role in pushing the limits toward higher resolution and precise and efficient machining of new materials.

Deep-ultraviolet microlithography particularly benefits from the shortest commercially available wavelength of 157 nm delivered by the F2 laser, offering the potential for the highest achievable resolution. Working at multikilohertz repetition rates, tens of watts average power, and with a spectral linewidth less than 1 pm, next-generation F2-laser-based microlithography systems will be capable of extending the minimum feature size achievable in mainstream chip production far beyond the 100-nm region.

Laser micromachining and laser material structuring gain specific momentum from the exceptionally high quantum energy of 7.9 eV of the 157-nm F2-laser radiation. These high-energy photons emitted at high peak power in ~15-ns pulses are observed to efficiently couple into optically transparent substances with wide bandgaps.

Because of the efficient absorption of 157-nm F2-laser radiation, clean and controlled microstructuring of amorphous and crystalline optical samples such as glasses, fused silica, and even quartz is feasible. In addition to their transparency at longer wavelengths, because such materials exhibit favorable dielectric and thermal properties, they are of increasing value not only in micro-optics applications but also in microelectromechanical systems (MEMS).

While processing transparent substrates is also possible at longer excimer-laser wavelengths, ablation thresholds are substantially higher and ablation rates are less controllable. As a consequence, unwanted formation of cracks and even the complete ejection of whole parts of the material, thermally induced by multiphoton processes, are facilitated.1

Beam-delivery system

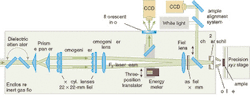

A beam-delivery and mask-illumination system has been developed for high-resolution material processing by MicroLas Lasersysteme (Göttingen, Germany), Laserlaboratorium Göttingen (Göttingen, Germany), and the University of Toronto (Toronto, Ont., Canada; see Fig. 1).2 The 157-nm laser beam enters from the left side. After appropriate attenuation, cylindrical lens arrays expand and homogenize the beam for uniform illumination of the mask at the desired laser fluence.

Using a Schwarzschild objective with 25x magnification, the illuminated mask is imaged onto the sample located on precision stages. The whole system is surrounded by a housing and flushed with inert gas. Using an F2 laser offering up to 50 mJ of pulse energy, the laser fluence available on the target amounts to several Joules per centimeter squared, which is enough to efficiently and smoothly microsculpt or pattern quartz and glass surfaces for various micro-optical applications such as manufacturing miniature lens arrays, photonic structures, or masks for 193-nm lithography.

Because the 157-nm laser fluence required for micromachining applications with polymers is typically an order of magnitude smaller, such a system is capable of covering all difficult-to-machine innovative materials by selecting the appropriate fluence for the sample.

Polymeric samples

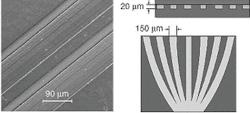

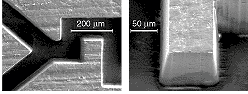

A structure machined into fused silica, with 100- to 160-μm-wide trenches and a depth of 40 μm, provides an example of applications requiring optical transparent substrates (see Fig. 2, left). In a following process step, these trenches are filled with a material that has a higher refractive index, and are covered by a plane-fused silica substrate to serve as planar waveguides (see Fig. 2, right). The energy density was 3.4 J/cm2 on the substrate. Direct writing speed was 0.3 mm/min at a 10-Hz repetition rate.3 The precise fabrication of such miniaturized systems plays a vital role in the development of integrated optical components for optical communication purposes.

Because of their electrical, mechanical, thermal, and chemical properties, clean ablation and structuring of the various functional polymers such as polytetrafluoroethylene (PTFE), polymethylmethacrylate (PMMA), and polyimide (PI) is highly desirable in numerous applications in electronics and biochemistry. While difficult to machine at longer wavelengths because of their lower absorption and increased thermal load, F2-laser processing of these different polymers at 157 nm yields excellent ablation characteristics.

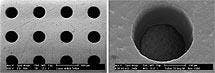

In a sample of PTFE, widely known as Teflon, that has been machined before the focal point of an f = 50.6-mm biconcave lens, the contact mask was located directly in front of the substrate (see Fig. 3). A mask with an array of 300-μm-diameter apertures on 600-μm center distance was used. The clearly defined edges visible on the 5x-magnified single bore to the right exhibit no signs of melting and resolidification, and are a clear indication for the cold ablation provided by the 157-nm F2 laser.

In contrast, the use of longer wavelengths requires significantly higher laser fluence to be applied on the sample and results in thermally overloading and locally melting the material. Large-area F2-laser processing of polymers with the obtained unsurpassed ablation quality can provide the basis for rapid prototyping of chemical and biological microanalysis and microreaction systems.4

Manufacturing of biomedical devices

Chemically inert quartz- and polymer-based microfluidic array platforms are apt to revolutionize various biomedical applications including assays of gene expression, proteomics, genotyping, DNA sequencing and fragment analysis, sample preparation, and high-throughput pharmaceutical discovery. Corresponding biological microsystems (BioMEMS) can act as microtiter plates with a size far less than that of a chip card and the advantages of considerably speeding up time for parallel analysis and reducing the required probe volumes.

High-volume fabrication of these microdevices requires a "zero-defect" master template that can be used for mass production via consecutive electroforming and injection-molding production steps. Fluorine lasers represent the ideal tools to create the complex arrangement of microfluidic channels and cavities contained in these master templates with superior accuracy and flatness. Undoubtedly, this is of particular importance in order to provide both excellent precision and highest reproducibility of the results given by such microsystems in applications such as microarray analyses for drug discovery and diagnostics.

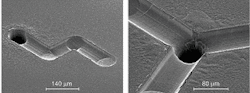

Microfluidic structures, the basis of the so-called lab-on-chip technology, are machined into quartz in a direct writing process (see Fig. 4). Curved cross sections were achieved by using a circular mask. In addition to the grooves, interconnecting through-holes with 40-μm diameter leading to the backside of the 200-μm-thick quartz substrate are machined in the same process without the formation of microcracks. Clean microreactor structures can be processed in PTFE with nitrogen used as ambient gas (see Fig. 5).

Furthermore, biocompatible—and perhaps biodegradable—polymers are important substrates for vascular implants, which are self-expanding miniature mesh tubes that are implanted in the arteries to keep blocked portions open after angioplasty procedures.

Working as scaffolding for the treated artery, stents must be flexible yet strong, and versatile in a variety of situations. In order to reliably keep the vessel open without injuring the surrounding tissue, extremely precise manufacturing that lends the machined structure its distinct mechanical behavior is a must. The corresponding accuracy can easily be achieved by the excellent ablation characteristics obtained in F2-laser machining of polymers.

The medical-device manufacturing industry represents another important field of application able to strongly benefit from F2 lasers that offer the highest commercially available photon energy, which is the prerequisite for controlled and clean ablation, avoiding thermal loading of transparent and polymeric strategic materials.

ACKNOWLEDGMENTS

We are indebted to P. R. Herman of the University of Toronto, Peter Oesterlin of MicroLas Lasersysteme, and J. Ihlemann of Laserlaboratorium Göttingen for providing information related to their 157-nm beam-delivery and mask-illumination system.

REFERENCES

1. P. R. Herman et al., Appl. Surf. Sci. 154-155, 577 (2000).

2. P. R. Herman et al., OSA TOPS 56, Conf. Lasers and Electro-Optics Tech. Digest, 574 (2001).

3.A. Ostendorf, U. Stamm, and T. Temme, SPIE Proc. LAMP (2001).

4. M. Lapczyna and M. Stuke, Mat. Res. Symp. Proc. 526, 143 (1998).

About the Author

Ralph Delmdahl

Ralph Delmdahl is product marketing manager at Coherent.