Graded antireflection grating lowers PC lens reflections

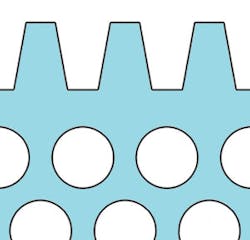

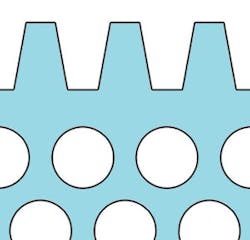

Because the characteristics of photonic-crystal (PC)-based optics are so complex, figuring out the best avenue for experimentation requires intricate numerical modeling first. Simulations of a flat 2-D PC lens done by researchers at Institut Fresnel, CNRS (Marseille, France) show the advantages of adding an optimized antireflection (AR) grating onto the lens's two surfaces. The PC is a dielectric structure with holes in a hexagonal lattice (bottom of figure), producing an effective refractive index near -1 at the design wavelength of 1.55 µm. In such a lens, light from an external point object focuses once within the lens and comes to a second, final focus on the side of the lens opposite from the object.

The PC material simulates indium phosphide or gallium indium arsenide phosphide. The elements of the AR grating are trapezoidal (top of figure). The reflectivity of the original PC surface ranges from 0.25 at normal incidence to about 0.9 at 75°. However, with the AR grating, the reflection is a mere 0.05 from normal incidence to 60° and rises only to about 0.15 at 75°. The simulation takes into account e-beam lithography fabrication requirements. Contact Boris Gralak at [email protected].

More Laser Focus World Current Issue Articles

More Laser Focus World Archives Issue Articles