Anyone who's been to an eye doctor has had experience with a phoropter—the bulky apparatus hanging from a metal arm and containing wheels of lenses that the doctor flips in front of the patient's eyes one by one. While the device is essential for determining lens prescriptions, the phoropter itself is big and complex, and the examination process is slow.

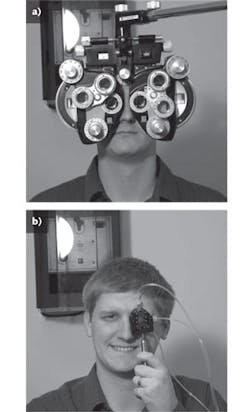

A group of researchers from the University of Arizona's College of Optical Sciences and its Department of Ophthalmology and Vision Science (both in Tucson, AZ) has demonstrated a new type of phoropter that is based on fluidically controlled lenses.1 The device is not only much smaller and simpler than a standard phoropter but can be easily computer-controlled, potentially shortening the examination process (see figure).

Monocle prototype

The researchers created a monocle phoropter as a prototype; the instrument could easily be doubled to form a binocular phoropter lightweight enough that it could actually be head mounted, allowing the patient to move his or her head without causing problems for the examination. The monocle phoropter is 13.7 mm thick and 44.5 mm in diameter and contains two astigmatic lenses oriented at 45° to each other, each with a correction from 0 to 8 diopters, and a spherical lens for defocus with a correction from -20 to +20 diopters. All three lenses can be continuously varied in power.

Each lens has a glass rear surface with a clear aperture of 12.5 mm, along with a 1.65 mm thick fluid reservoir defined by an elastic membrane made of polydimethylsiloxane (PDMS); the reservoir can thus be further filled with or emptied of fluid (deionized water, in this experiment). The membrane for the defocus lens is held by a 23 mm diameter ring, while the membranes for the astigmatic lenses are held by rectangular clamps 30 × 16 mm in size.

The researchers fabricated the membranes, molding them on an optically smooth glass plate (the other side of the membrane is close to being index-matched with the lens fluid so it does not have to be as flat). The membranes were then placed in a vacuum for a short time to remove air bubbles.

The visual Strehl ratio computed in the frequency domain for the defocus lens was greater than 0.75, and for the astigmatic lens was greater than 0.98. Because varying the astigmatic lenses also produces variations in spherical power, the phoropter was characterized with a Shack-Hartmann sensor (at a wavelength of 53 nm) so that the spherical and astigmatic lenses could be operated together to produce just a cylindrical variation in wavefront when needed.

Model-eye testing

To further test the phoropter's imaging quality, a model eye was fabricated containing a 20-diopter intraocular lens placed in a saline-filled chamber with a 6 mm diameter pupil. Various spherical and cylindrical lenses were placed in front of the model eye to simulate refractive error in the eye. An image of a cat through a refractive error of 2 diopters spherical and 1 diopter cylindrical showed as a blur; the same image corrected by the phoropter was visually as sharp as the image without any initial refractive error present.

The next step in the development of the phoropter is to automate the tool, notes David Mathine, one of the researchers at the College of Optical Sciences.

REFERENCE

- R. Marks et al., Opt. Lett. 35, 5, p. 739 (Mar. 1, 2010).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.