NARROW-LINEWIDTH LASERS: Small resonator-stabilized laser has 13 kHz linewidth

Lasers with linewidths in the low kilohertz range are useful for spectroscopy as well as metrology (for example, length and frequency standards). Researchers at the Max-Planck-Institute for the Science of Light (MPL; Erlangen, Germany) have come up with a simple and compact form of this type of laser that has a linewidth of only 13 kHz.1 The laser is built around a small whispering-gallery-mode (WGM) resonator made of crystalline calcium fluoride (CaF2). When formed into a disk, a CaF2 WGM can have a very high Q factor (the Q factor is a measure of a resonator's damping; a higher Q indicates less damping).

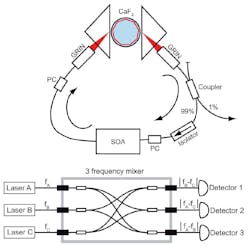

The laser assembly is made of a ring of optical fiber with all the relevant optical components inserted into the ring (see figure). A semiconductor optical amplifier (SOA), which provides a spectrally broad emission with a peak around 1560 nm, provides the laser gain; the SOA is placed between two polarization-control (PC) components, and an optical isolator ensures that laser light is produced in only one direction. A fiber coupler directs 1% of the circulating light into an output fiber.

Resonator is fabricated in-house

The heart of the laser is the WGM resonator itself and the prisms that couple light into and out of it. The 5 mm diameter resonator was turned and optically polished on equipment custom built at MPL. Laser light is coupled into and out of the resonator via two prisms, each placed close to (but not touching) the resonator so that a small amount of light couples evanescently from one prism into the resonator, and then out of the resonator into the other prism. Light from the fiber ring is brought into and out of the prisms via a pair of gradient-index (GRIN) lenses. The prisms are aligned so that the assembly lases in a single mode; a mode around 1560 nm is automatically selected due to mode competition in the laser.

The resonator, which has a measured passive linewidth of 15 MHz, or a Q factor of 107, is mounted on a thermoelectric cooler to control its temperature (note: the passive linewidth is just a property of the resonator and is not the laser's actual linewidth). When the SOA is pumped with a 600 mA electrical current, about 10 μW of optical power is emitted from the 1% port.

Three-cornered hat

The researchers chose to measure the laser linewidth two different ways. First, they set up a so-called "three-cornered hat" measurement system, in which three different light sources are compared to each other, yielding the linewidths of all three. In addition to the CaF2 resonator laser, a 1550 nm diode laser with a 100 kHz linewidth and a custom-built grating-stabilized laser were included. Outputs from the three lasers are beat with each other and the beat notes measured and recorded. An Allen-variance analysis showed that the CaF2 resonator laser reached its highest time-scale-dependent stability at 10 μs, with white phase noise higher at shorter time scales and random frequency walk increasing at longer time scales. The analysis implied a fast (short-time-scale) linewidth of 2 kHz at 10 μs.

A second measurement approach, self-heterodyne beating using a delay line, helped determine the longer-term linewidth. Here, the laser light is split with an acousto-optic modulator, with one half of the light frequency-shifted by 100 MHz and sent through a 45 km fiber delay line. The resulting self-heterodyne linewidth was 18 kHz; the intrinsic Gaussian linewidth was calculated to be 13 kHz.

The researchers plan to experiment with resonators that have a higher Q factor to further decrease the linewidth, possibly to subkilohertz widths. They also note that the SOA could be replaced by an erbium-doped fiber if output at 1530 nm were desired.

REFERENCE

1. B. Sprenger et al., Opt. Lett., 35, 17, 2870 (Sept. 1, 2010).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.