The rapid growth in the transmission capacity of fiberoptic waveguides would be of little value if there was not an equal growth in modulation rates. Because the whole aim of electro-optics is the transmission and processing of information, the crucial link between electronics and optics has always been the modulation of light by electrical signals to transfer the information from electrical to optical form. Today, a few basic types of electro-optical crystals, such as lithium niobate (LiNbO3), provide the backbone of high-speed light modulation (see photo at top of this page). But in the search for ever-higher data-transfer rates, researchers are developing new polymer materials and entirely new electro-optical processes such as surface plasma resonance. Such new technologies will be needed as data rates approach and exceed 100 Gbit/s. At the same time, the venerable light-modulation technology of liquid-crystal displays (LCDs) is expanding into new niches, with larger color capacities.

Principles of carrier modulation

There are three common methods of modulating light signals—amplitude-shift keying (ASK), frequency-shift keying (FSK), and phase-shift keying (PSK). Amplitude-shift keying is the simplest approach—the amplitude of the signals is changed to code either a "zero" or a "one." This coding can be done by either an external modulator or by directly modulating the output of a semiconductor laser, for example, by changing the driving current. Direct modulation has the disadvantage of introducing frequency changes as the injection current varies, although this can be stabilized by injection-locking the laser with another stabilized laser.

In frequency-shift keying, one frequency codes for a "zero" and another for a "one." Receivers tuned to the two different frequencies can be used, or, more commonly, a single receiver is used, with a passband filter that admits only one of the two frequencies, thus producing an on-off amplitude-shift keyed signal. Here again, the frequency modulation can be imposed externally by an electro-optic modulator or directly by altering the drive current on the laser.

Both of these methods can use a carrier signal with a low level of coherence—that is, in which there is a range of phases in the output light waves. Similarly, both can tolerate a fairly broad linewidth—particularly ASK. In contrast, phase-shift keying requires a highly coherent beam with a very narrow linewidth. In this method, a "one" is transmitted by changing the phase of the waveform 180° between successive bits, while a "zero" is coded by leaving the phase the same between bits. Because the phase is critical, the need for high levels of coherence follows directly from this. However, only bit-to-bit coherence is needed so slow phase drift is tolerated. External modulation is the rule here, and phase modulation can potentially provide the highest bit rates.

Physical processes of modulation

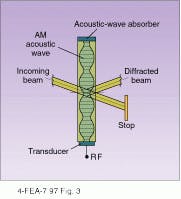

To produce modulation, some optical property of a material must be changed in response to an electrical signal. Electro-optical modulation does this directly, using materials whose indexes of refraction or other properties change in response to electrical fields. More indirect methods include acoustic-optical and magneto-optical effects, where mechanical distortion or a magnetic field produced by electrical currents in turn modifies optical properties.

Electro-optical modulators generally rely on one of two nonlinear optical effects: the Pockels effect and the Kerr effect. The first is a second-order nonlinear effect in which the refractive index varies in relation to the applied electric field, while the second is a third-order effect in which the index varies with the square of the electric-field strength. Typical Pockels-effect materials included noncentrosymmetic crystals such as lithium niobate, lithium tantalate, and potassium dihydrogen phosphate (KDP). Kerr-effect materials include these crystals, but also some centrosymmetric crystals, glasses, gases, and liquids.

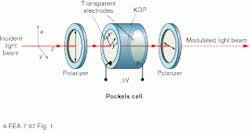

In a typical Kerr- or Pockels-effect modulator, the electro-optical material, for example KDP, is placed between two crossed polarizers, with its optical axis along the z direction, in the direction of the light beam (see Fig. 1). When a field is applied, the light polarized by the first filter (say, in the vertical direction) is absorbed by the second filter, and no light is transmitted. But when a field is applied in the z direction, the KDP becomes a biaxial material, with the principal axes oriented at 45° to the initial polarization direction. This causes the initially vertically polarized beam to split into two perpendicularly polarized components, each at 45° from the vertical. These two polaraizations travel at different speeds through the cell, a difference that depends on the voltage applied.When the voltage is sufficient to shift the two waves by 180°, the lightwave is horizontally polarized, in effect rotating the initial polarization by 90°. It thus passes through the second polarizer without absorption. When the voltage produces only a 90° phase shift the resulting wave is circularly polarized, and half the light is absorbed by the second polarizer. The result is amplitude modulation at gigahertz rates.

If the crystal is reoriented so that the electrical field is transverse to the light path, applying the electrical field alters the index of refraction for the entire wave, and thus the phase shift is proportional to both the applied voltage and the length of the crystal. This makes possible the use of lower voltages and produces a phase-shift keyed modulation.

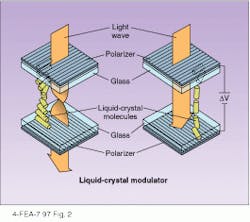

Although Kerr- and Pockels-effect modulators are key in high-speed communications, liquid-crystal electro-optical modulators play an even more central role in display technologies, where speed is less important than energy efficiency. Again the basic principle is the rotation of polarization between two crossed polarized fields (see Fig. 2). In liquid crystals, the long axes of elongated organic molecules all line up in the same direction. A twisted nematic liquid crystal is prepared in an LCD cell in such a way that the preferred axis rotates 90° between the front and back of the cell. Polarized light passing through the cell is similarly rotated 90° allowing passage between crossed polarizers. But when an electrical field is applied, the crystals line up along the field direction, preventing the rotation of polarization direction and thus allowing the light to be blocked by the second polarizer. Until recently, LCDs were monchromatic, but there is now an intensive effort to develop color LCDs, using triplets of LCDs each topped with a different-color filter.Modulating materials

By far the most commonly used material for high-speed communication modulation is LiNbO3. Using the Pockels effect, LiNbO3 devices have achieved 29-GHz bandwidth with a 5-V driving potential. However, optical communications designers are continuously searching for ways to reduce the driving potential and to increase bandwidth. So, while lithium niobate can yield about 8 GHz/V, indium gallium arsenide phosphide (InGaAsP) modulators can achieve as high as 26 GHz/V.

Such semiconductor-based modulators contain multiple quantum wells. Quantum wells are formed when a layer of material in a semiconductor is made sufficiently thin, less than 50 nm, and quantum effects become important because the electron location is so restricted in one dimension. The result is that the conduction band and valance band split into sub-bands, and the probability of a transition across the bandgap also changes. Such layers can be stacked, alternating with inactive layers, producing multiple-quantum-well structures.

In these quantum wells, an applied electric field alters the energy levels through the Stark effect. Varying the levels allows the material to heavily absorb light of the laser frequency when a field is applied, but not when there is no field. By applying a tensile strain to the metal, the absorption effect can become the same for all polarizations, producing a polarization-independent modulator, in contrast to Kerr- and Pockels-effect modulators, which require a fixed polarization. Such independence can be of great benefit when a modulator is used as a repeater to reshape signals. Here, polarization direction may have been altered by transition through many kilometers of optical fiber.

While not yet in commercial use, nonlinear optical polymers could eventually provide better performance than electro-optical crystals. Such polymers have highly polarizable chromophores that line up with the electric-field direction during fabrication. Researchers believe that such polymers could eventually yield bandwidths of close to 100 GHz, nearly three times that of lithium niobate. In addition, such polymers could be more compatible with silicon, making monolithic integrated-circuit fabrication easier.

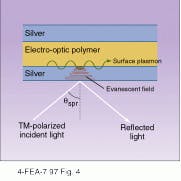

Such electro-optical polymers can use new physical methods to produce modulation. For example, in a surface-plasmon-resonance device developed at the University of Washington (Seattle, WA), light reflected form a thin silver film produces an evanescent field that penetrates a short distance through the silver into the polymer layer (see Fig. 4). There it excites a surface plasmon wave, a wave of lattice excitation, in the polymer film. At a unique angle of incidence, a resonant coupling occurs, and the light is absorbed. If an electric field changes the index of refraction of the polymer, the resonance is destroyed and the light is no longer absorbed.With current waveguide technology, modulation speeds become the limiting factor only for very short fiber spans (under about 3 km). As new technology comes on line, modulation speeds should keep pace, avoiding bottlenecks in delivering volumes of high-speed communications and data.

FURTHER READING

J. E. Midwinter and Y. L. Guo, Optoelectronics and LightWave Technology, John Wiley and Sons, New York, NY.

C. Jung, S. Yee, and K. Kuhn, Appl. Opt. 34, 946 (Feb. 20, 1995).

F. Devaux et al., Semicond. Sci. Technol. 10, 887 (1995).

About the Author

Eric J. Lerner

Contributing Editor, Laser Focus World

Eric J. Lerner is a contributing editor for Laser Focus World.