Deep-ultraviolet coatings resist optical damage

Deep-ultraviolet coatings resist optical damage

Fluoride materials and iterative process development increase lifetimes of reflective coatings for excimer laser optics by an

order of magnitude.

David Collier and Wayne Pantley

The output characteristics of the excimer laser make it well suited to a variety of precision material-processing and biomedical applications. Until recently, however, optical damage to the beam delivery optics, and to the coatings in particular, has limited reliability of these systems. Optics manufacturers have addressed this problem, extending typical coating lifetimes by more than an order of magnitude. New research programs should lead to further improvements in damage resistance.

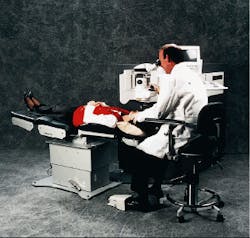

The fastest-growing applications areas for excimer lasers are photorefractive keratotomy (PRK) and microlithography. In PRK, an ablative eye surgery to correct myopia, beam uniformity and pulse energy must be tightly controlled to ensure a successful outcome (see Fig. 1). These parameters are directly affected by any degradation in the multilayer dielectric coatings on the mirrors and beamsplitters used in the beam-delivery system. Until recently, many systems in the field required replacement of several optics during scheduled service and maintenance, with a typical service interval of four to six months. The total cost of the system optics (u¥to $10,000) is quite significant in comparison to the typical service contract costs of $40,000 to $50,000 per year.

After years of using successively shorter mercury arc lam¥wavelengths, microlithography is now turning to 248- and 193-nm excimer lasers to provide the resolution for the next generation of integrated circuits (ICs). Although lithographic applications require fluences as much as an order of magnitude lower than those required for PRK, the economics of continuous equipment operation make failure of systems optics a much greater problem for lithography than for PRK. Lithographic steppers must operate around the clock; estimates for total downtime costs can reach several hundred thousand dollars per hour for 248-nm systems and more than a million dollars per hour for 193-nm systems. To minimize losses, the total number of laser pulses that must be sustained by the optics between changes must be on the order of hundreds of millions of pulses.

Thus, economics dictate the need for robust, high-reflectivity optical coatings for 193- and 248-nm wavelengths. In 1994, we began a program at Alpine Research Optics (Boulder, CO) to extend the coating lifetimes for deep-ultraviolet (deep-UV) excimer laser optics. We have produced mirrors with lifetimes of five million pulses at 193 nm, an increase of an order of magnitude over the half-million-pulse lifetimes previously achieved (see Fig. 2).

Defining failure

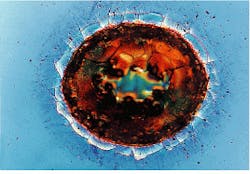

In optics used for high-energy, long-wavelength lasers such as neodymium-doped yttrium aluminum garnet (Nd:YAG) systems operating at 1064 nm, failure has usually meant catastrophic damage--the coating is pitted, burned, or partially blown off the substrate (see Fig. 3). In the case of short-wavelength excimer photons, damage mechanisms are different and performance deterioration may occur long before catastrophic failure takes place. For ultraviolet reflective optics, failure has therefore been defined by some arbitrary decrease in reflectivity.

In both PRK and microlithography, failure is defined as a 5% decrease in reflectivity; in the case of PRK, a coating uniformity decrease of more than a few percent also constitutes failure. The 5% value stems from the large number of optics used in these systems. A typical lithography system, for example, may contain as many as 12 fold mirrors just in the laser projection section--a 5% dro¥in reflectivity on each of 12 mirrors used in series would thus decrease the delivered beam energy by 50%.

In lithography, decreased pulse energy slows the exposure process, costing time and money. Excimer laser damage is an accelerated process--a 5% dro¥in reflectivity will quickly become a 10% decrease. End-user economics dictate that the optics be replaced as soon as they begin to show noticeable (5%) signs of deterioration and certainly long before catastrophic failure is a possibility.

The first obstacle we encountered in the coating development program was a lack of understanding about the mechanisms leading to damage and failure. It was soon apparent that what we knew about producing long-lifetime laser mirrors for visible and near-infrared wavelengths did not apply to mirrors for deep-UV wavelengths. For example, in pulsed Nd:YAG lasers operating at 1064 and 532 nm, coating damage is related to peak power. Flashlamp-pumped Nd:YAG lasers with beam hot spots are notorious for quickly producing burns and pits in both coatings and substrates.

In contrast, ex cimer laser damage appears to correlate more closely with total accumulated flux. The operating atmosphere also plays an important role. "We used to see significant optics lifetime differences between individual medical facilities," notes George Caudle of PRK system manufacturer Visx (Santa Clara, CA). "We suspected this was due to differences in air quality. This was confirmed by enclosing the op tics in a closed, filtered environment, which significantly reduced these site-specific performance anomalies." Possible mechanisms for decreased coating reflectivity include photo-oxidation-induced refractive index changes and/or absorption increases, problems with the coating-to-substrate interface, and solarization of the coating layers. Research programs are underway to investigate these issues (see "Testing optics for damage," p. 82).

Another problem we faced in coating development was the lack of reliable testing protocols for certifying optics. The conventional qualifying specification for excimer optics is resistance to several high-energy pulses (2 J/cm2). Although this is acceptable for Nd:YAG optics, it is not a useful diagnostic for deep-UV excimer laser optics. Coating designs can be independently optimized for either high-peak-power resistance or longer life, so data from peak-power tests can be misleading.

With no rapid testing method and no definitive information about failure mechanisms, we had to partner with our OEM customers to improve coatings. Over a two-year period, we systematically refined coating designs and chamber conditions in an iterative manner, relying on feedback from end users about the actual performance of each batch of coatings to improve our fabrication techniques.

Process control

Creating robust coatings for use at 248 nm proved to be much simpler than for 193 nm. Hafnium oxide (HfO2), the principal compound for use at 248 nm, is a well-characterized coating material that acts as a high-refractive-index layer in a reflective multilayer stack. The material becomes absorptive at wavelengths below 226 nm, however, so it is not useful for 193-nm optics. For these coatings, we had to develo¥a proprietary design based on a combination of fluorides for both the high- and low-index layers. We chose not to use thorium fluoride, a material sometimes used by others because of its desirable optical properties, because it is a toxic, radioactive material that requires methods of handling and disposal approved by the Environmental Protection Agency and Occupational Safety and Health Administration.

During our development process, we found that the temperature of the substrate during deposition is one of the most critical parameters for production of stable coatings. If the temperature of the optic is too low, the fluorides deposit poorly with unpredictable refractive index and shortened lifetime. If the temperature is too high, the coatings tend to fracture, or craze, as the optic cool. The iterative development process allowed us to determine the optimal substrate temperatures for deposition of these coatings.

Electron-beam evaporation

Coating researchers have developed several techniques in recent years--most notably ion-assisted deposition--to improve optical coating layer hardness and consistency. In the case of the fluorides used for deep-UV mirrors, however, ion-assisted deposition typically increases short-wavelength absorption, actually reducing the lifetime of the optic.

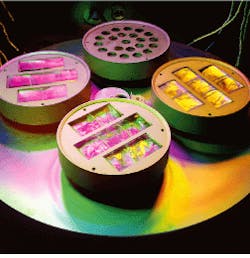

To avoid this problem, we use a conventional electron beam to evaporate the fluoride coating materials. Electron-beam evaporation provides good material distribution and consistency throughout the coating chamber. By ensuring uniformity of substrate temperature during the deposition process, we have produced robust, high-quality coatings on batches of 1 to 100 components with diameters u¥to 8 in. (see photo on cover and on p. 77).

By making continuous, incremental improvements to our coating process, we have increased the lifetime of our 193-nm mirrors from 0.5 million to 5 million pulses at 200mJ/cm2, as certified by Spica Technologies (Nashua, NH). "We have been shipping our latest-model PRK system [incorporating ARO-coated optics] for about 18 months," says Visx`s George Caudle. "In that time we`ve seen a dramatic reduction in optics failure." o

Optics with reflective ultraviolet coatings have applications in photo refractive keratotomy and in microlithography at 193 and 248 nm. The varigated appearance of the optics is caused by protective foil on the bottom of the optics reflecting overhead lighting.

FIGURE 1. Photorefractive keratotomy systems allow surgeons to correct myopia in patients by ablating the cornea with output from an excimer laser.

FIGURE 2. The last three to four years have seen a tenfold increase in excimer turning mirror lifetimes. All data are based on a fluence of 200 mJ/cm2 per pulse, and lifetime represents time to 5% dro¥in reflectivity.

FIGURE 3. Optical failure in long-wavelength, high-powered systems is defined as catastrophic damage such as the holes burned in the coatings and substrates of these Nd:YAG mirrors. In excimer laser mirrors, damage is usually less catastrophic and not always obvious to the naked eye.

Testing optics for damage

The production of robust, high-reflectivity optics for excimer applications has been hampered by the lack of both definitive information about failure mechanisms and lifetime testing data and models. Work now being conducted on optical coatings should lead to improvements in the reliability of these optics. "Most of the existing research on excimer damage of optics has focused on the bulk materials," says Mordechai Rothschild of MIT Lincoln Laboratory (MITLL; Lexington, MA). "With multielement lithography lenses for 193 nm costing several million dollars each, naturally attention has been directed to finding long-life substrates for the lenses. But now, the importance of prolonging the life of their antireflective coatings and the reflective optics has been fully recognized."

One of several research programs aimed at this problem was recently funded by SEMATECH at MITLL. This grou¥plans to use a variety of optics techniques to monitor the changes in microscopic and macroscopic properties of single and multilayer coatings.

In the area of testing, companies such as Spica Technologies Inc. (Nashua, NH) now offer rigorous life testing of optics as a service for both manufacturers and end users. Mike Thomas, chief scientist and president of Spica, says, "At present, true life testing of these optics is essential. In the past we have avoided this type of testing because it is very time-consuming and requires several dedicated excimer lasers. A recent cooperative agreement with J. P. Sercel Associates Inc. (Hollis, NH) has enabled us to offer the first commercial life testing of excimer optics from 157 to 308 nm.

"As we collect additional data, we hope the results of these experiments will lead to the development of a life-test model. This may allow us to reliably extrapolate shorter test data, which will be to everyone`s advantage."

D. C. and W. P.