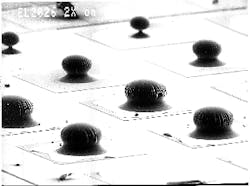

A novel mushroom-shaped lens, developed by IMEC (Leuven, Belgium) and VUB-ETRO (Brussels, Belgium), en hances output efficiency and directivity of light-emitting diodes (LEDs) by up to a factor of eight. The work was done by Jan Genoe, Martin Kuijk, and Roger Vounckx from VUB-ETRO and IMEC and by Paul Heremans and Gustaf Borghs from IMEC. The group integrated these lenses directly onto LEDs (see photos).

"The problem of LEDs made from gallium arsenide (GaAs) is that the index of refraction for GaAs is such that only light generated at an angle of less than 17° with respect to the top or upper surface is emitted. The rest of the light is lost due to total internal reflection," says Genoe. Microlenses with diameters of a few microns to a few hundred microns are currently used to boost the efficiency of semiconductor optical devices such as detectors and emitters. When an LED is integrated with a single lens, the total light output is enhanced by two orders of magnitude.

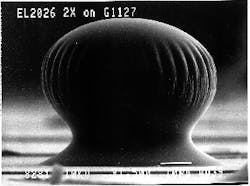

The researchers` aim was to use three lenses on top of an LED, hoping to further optimize the throughput. Genoe says, "Our first intention was to put lenses on a pillar, to be more efficient. But after we reflowed the photoresist, we had a beautiful raised curvature. This mushroom-shaped lens was comparable to three lenses and much better for focusing light."

The lens dome is located at a specific controllable distance from the substrate, and the curvature of the lens is larger than that of traditional truncated-sphere lenses. The lenses are equilibrium-state, stable products of reflow that are obtained when starting from a multilayer photoresist stack.1

A popular technique of lens fabrication is photoresist reflow. A single-layer circular photoresist island is heated to above the reflow temperature, allowing the resist to draw into a truncated-sphere shape, and then solidified by cooling down. The researchers used a special photo resist that produces a very thick resist layer (Morton EL2026). This material typically results in a 15- to 20-µm layer when spun at 2500 to 3000 rpm, says Genoe. "We used multiple layers and different curing temperatures so the bottom layers would dry before the top." This produces a lens consisting of two types of materials--an illuminated photoresist in the lower region, originating from the layers that were flooded uniformly with light and dried extensively, and non-illuminated photoresist in the upper region. The resulting optic is a plano-convex spherical microlens that can be formed on a variety of substrates, including semiconductors or glass.These optics can also be aligned on top of devices that are already present in the substrates. Their curvature is stronger than that of conventional truncated-sphere photoresist microlenses, and the distance of the lens to the substrate is controllable. Such properties permit optimization of shape for specific applications. When combined with LEDs, for instance, they can be used to maximize the directionality of the output beam, to optimize the external quantum efficiency, or to focus the light on a spot at a specified distance.

Although patented, these lenses are not yet commercially available. IMEC is looking for a partner company to develop them for market.

REFERENCE

1. P. Heremans et al., Photon. Technol. Lett., 1367 (Oct. 1997).

About the Author

Laurie Ann Peach

Assistant Editor, Technology

Laurie Ann Peach was Assistant Editor, Technology at Laser Focus World.