Optoelectronic technology generates information with sources and sensors and transmits it through optical fibers for optical communications. Information is processed with optoelectronic computers and, perhaps most ubiquitously, it is displayed on a variety of flat-panel devices. By far the most widespread of these display technologies is the liquid-crystal display (LCD). First introduced as a low-energy device for pocket-calculator displays, LCDs now dominate the market for portable-computer displays and are beginning to compete for the burgeoning new markets of flat-panel TV.

But to fully match the capability of the venerable cathode-ray tube (CRT), researchers are having to overcome many significant limitations of early LCD technology. They are developing displays that are significantly brighter and have better color, wider viewing angles, and less flicker than the LCDs now in common use. Indeed, they are now starting to exploit the possibilities of LCDs to aim for that Holy Grail of displays—real-time, full-motion, three-dimensional displays that need no viewing glasses.

Basic principles of LCDs

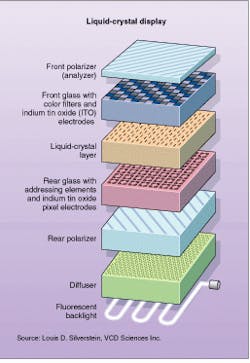

A liquid crystal is a material in which molecules line up with each other in regular arrays, as in a crystal. But the bond between the molecules is sufficiently weak so that the molecules can also slide past each other and reorient when subjected to mechanical or electrical forces. Conventional LCDs generate images when a voltage is applied across cells of liquid crystals, causing the liquid crystals to twist. This in turn rotates the polarization of light passing through the cell. By placing the cell between crossed (or parallel) polarizers, a light valve is created that allows light through only when a voltage is on or off—depending on whether the polarizers are crossed or parallel (see Fig. 1).

The key problems with this approach have been low contrast and narrow viewing angles. In a conventional LCD, voltage is applied to a row and column to produce an above-threshold voltage where the row and column cross. But this process applies near-threshold voltages to neighboring pixels, creating partial twisting and decreased contrast. In addition, if the display is viewed at an angle, some light will travel through two neighboring pixels, again cutting contrast.

To overcome this problem, advanced LCDs for high-performance uses such as flat-panel computer terminals use active-matrix thin-film technology. With an active matrix, each pixel is equipped with its own thin-film transistor, and the entire screen becomes a giant memory chip. When the transistor is activated, it applies the voltage to its pixel alone, greatly increasing contrast. The viewing-angle problem is attacked by making the panel thin compared with pixel width, so that a large angle is required before substantial light is lost. Finally, color can be added simply by applying thin-film filters to the front panel.

The biggest application of LCDs today remains in laptop computers, but with prices of displays dropping rapidly and production expanding, manufacturers are actively invading new markets. One potential large market is monitors for desktop PCs, where the much smaller size of LCDs compared with CRTs can be useful on crowded desks. Another application in which LCDs are already largely replacing CRTs is in high-end instrumentation, where both size and weight is at a premium—CRTs generally account for one-third to one-quarter of the total weight of the instrument.

Possibly the largest market over the long run may be in automobile-navigation devices. Here, LCDs are the display of choice for showing the maps and directional advice that navigational systems generate. While these displays are currently installed only on luxury cars, the basic technology is quite inexpensive, and over time LCDs may become a standard feature in many cars.

For the new applications, performance of LCDs has to advance and overcome existing limitations. Most important, viewing angles have to be increased. While CRTs can be viewed from any angle, LCDs that are viewed head on from too far away either wash out or produce color-inverted images. Typically, existing active-matrix LCDs have viewing angles of 䕑° in the horizontal direction and 䕂° in the vertical direction, but many applications, especially automotive-based ones, need wider viewing.

In addition, conventional LCDs are actually filters that eliminate half of the light that passes through them, even when they are in the "on" state. Color filters in front of the cells reduce light further, so that color LCDs generally require back lighting for adequate brightness, driving energy costs up and portable-computer-battery lifetimes down. The resolution and contrast of LCDs impose other limits. The very high contrast and sharp resolution needed for electronic books, for example, or the fine cell spacing required by very small, wrist-top displays, are beyond conventional fabrication capabilities.

Expanding the viewing angle

A number of efforts are under way to expand viewing angles. One approach is to divide each LCD pixel into subpixels, each optically tilted in a different direction. The problem with attempting such an approach is that no one knew until recently how to tilt the liquid-crystal molecules, which naturally tend to line up parallel to the cell surfaces. Last year, however, a team of physicists and chemists at the R&D organization Rolic Ltd. (Basel, Switzerland) demonstrated that linearly polarized ultraviolet light could align and crosslink polymer-film coating substrates that contain liquid crystals. These polymers, in turn, force the adjacent layers of liquid crystal to orient in the same direction. By tilting the crystal alignments differently in each of four subpixels in each pixel, LCDs could be produced with considerably wider fields of view.

Less dramatic technical advances have already been used to increase viewing angle. For example, by introducing an optical-compensation layer above the LCD layer, researchers at Sharp Electronic Corp. (Camas, WA) has demonstrated a 䕪° horizontal and 䕛° viewing angle in an experimental active-matrix LCD.

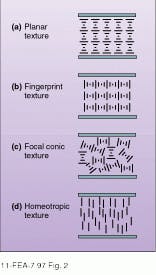

There are also a number of efforts to improve the brightness of LCDs. One of the most promising involves the use of cholesteric liquid crystals, pioneered at Kent State University (OH). Cholesteric liquid crystals are either composed of chiral molecules or have chiral dopants (chiral molecules are those that twist in a preferred direction). Such liquid crystals form arrays of tight helixes, with the pitch of the helix being comparable to the wavelength of light. These, sandwiched between two parallel plates, form a stable array that strongly reflects light with a wavelength determined by the helical pitch. Because the pitch can be determined by the selection of the material and by the length of time the material is exposed to UV radiation, the LCD cells can have intrinsic colors that are much purer and more brilliant than those formed by conventional filters. In addition, because the LCD is not filtering the light for polarization, each "on" pixel is about twice as bright as those of a conventional LCD.

To turn a pixel off, an electric field is applied that exerts a torque on the helixes, causing them to untwist, making the cell transparent and thus dark (see Fig. 2). When the field is reduced slowly, the cell relaxes into a state in which the helixes are randomly oriented, producing a scattering medium with poor reflection, and the cell remains dark. So both the on and off state can be maintained without a field and without any energy expenditure.Although cholesteric LCDs may prove ideal for such applications as electronic books, many companies have their eyes on the potential of hang-on-the-wall TV screens. In this application, brightness levels are critical. A new alternative is to turn each LCD pixel into a laser. Nabil Lawandy and colleagues at Brown University and Spectra Science (Providence, RI) have shown that a polymer-dispersed liquid crystal can act as a switchable laser (see Laser Focus World, Mar. 1997, p. 15, and May 1997, p. 137).

In a polymer-dispersed liquid crystal, the liquid crystal is suspended as droplets in a water-based polymer. Without an electric field, the liquid-crystal drops are randomly aligned, scattering light and preventing lasing. When the field is turned on, the liquid crystals align, making the cell transparent and allowing lasing (see Fig. 4). The Brown researchers are working on a US Department of Defense grant aimed at developing extremely small, high-resolution displays and believe they can design pixels as small as 20 µm on a side, thereby creating a display with 100,000 pixels per square centimeter.While polymer-dispersed and cholesteric LCDs alter the nature of the liquid crystal itself, another approach is to alter what happens to the light after it leaves the cell. A number of research groups are using diffraction gratings to enhance performance and to open the way to three-dimensional (3-D) displays. For example, Philip Alvelda of the Massachusetts Institute of Technology (Cambridge, MA) is using diffraction gratings in the base of each cell, rather than filters, to produce a single spectral pure color. As with the approaches just described, this design allows for much smaller cells than conventional arrays, in which a mask of filters has to be aligned with the underlying LCD array. Alvelda can achieve pixels a few microns across, well below the several tens of microns needed to achieve the highest resolution the human eye can see. (Alvelda’s company, MicroDisplays, Berkeley, CA, is working to commercialize this technology; see Laser Focus World, Feb. 1996, p. 25.)

Diffraction gratings are featured in a number of other schemes for 3-D displays, all of which work on the same basic principle--each pixel is divided into subpixels, with a diffraction grating directing the light from each subpixel in a different direction. The scenes feeding each set of subpixels are different views of the same objects, so that each eye revives a slightly different view, creating the stereoscopic illusion of depth (see Fig. 5). Typically, initial experimental prototypes developed independently at the University of Alabama (Huntsville, AL) and Toppaz Printing (Tsukuba, Japan) have 3 × 3 or 4 × 4 subpixels per pixel (see Laser Focus World, April 1996, p. 39). These designs will, in theory, allow several viewers to look at the display at one time or the viewer to move his or her head without spoiling the illusion. The extremely small pixels that may be made possible by diffraction or other new technologies might allow a large number of subpixels and a high degree of 3-D fidelity.The engineering challenges remain significant in moving these ideas from the research laboratory to the consumer electronics store, but it now seems possible for the combination of technologies to provide, some years from now, a wall-sized, full-color 3-D TV, long a staple of scientific fiction.

FURTHER READING

G. P. Norton et al., Opt. Engineer. 35, 3404 (Dec. 1996).

"On Permanent Display," Scientific American, p. 32 (May 1996).

D. K. Yang et al.,"Polymer-Stabilized Cholesteric Structures," in Liquid Crystals in Complex Geometries, C. P. Crawford and S. Zurner, eds., Taylor and Francis, London, England, 1996, p. 105.

About the Author

Eric J. Lerner

Contributing Editor, Laser Focus World

Eric J. Lerner is a contributing editor for Laser Focus World.