Adaptive optics reveals its commercial potential

Adaptive optics (AO) has reached a critical turning point in its commercial evolution. The technology has been exploited for many years in astronomy with so much success that nearly all new ground-based telescopes incorporate tailor-made AO systems to remove the optical distortions caused by turbulence in the Earth's atmosphere. These complex AO systems, which typically cost upwards of $1 million, are designed and built to optimize the image quality that can be achieved with an astronomical instrument.

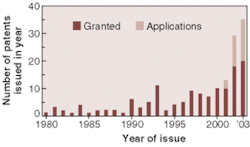

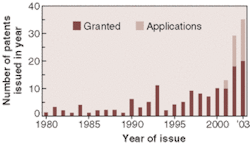

Now, however, the commercial sector is starting to explore the potential of AO in a range of industrial and medical applications (see Fig. 1). As a consequence, the AO community is shifting its focus toward developing smaller and cheaper components that can be easily bolted together by nonexpert staff. This transition from customized design to mass-market manufacture must take place within the next five years if AO is ever to become a commercial success with credible and sustainable growth prospects.1

Most commercial activity thus far has focused on the lucrative industrial-laser market because AO can play a crucial role in manipulating and controlling laser beams, either by modifying the properties of the laser resonator or by altering the characteristics of the output beam (see Fig. 2). Companies such as Trumpf (Schramburg, Germany) and Diehl (Nuremberg, Germany) are already marketing commercial AO systems to provide accurate focus control of high-power carbon dioxide lasers, while manufacturers of industrial solid-state lasers are keen to exploit AO to maintain laser performance over a range of output powers.

Laser manufacturers have indicated that AO systems would be fitted to almost every high-power solid-state laser if the extra cost were no more than $10,000—around 10% of the price of a typical industrial laser system. Building an intracavity AO system below this price threshold should be feasible with bimorph mirrors, which can also be cooled to handle the high power levels. The big challenge now is to bring down the price of the high-voltage power supplies needed to control these mirrors, which can cost as much as the mirror itself.

In the meantime, lower-cost membrane mirrors offer an alternative for applications requiring modest power levels. The main supplier of membrane mirrors, Flexible Optical (Delft, The Netherlands), has shown that these mirrors can handle power levels ranging from a few tens of watts up to 500 W with no loss of performance.

Another crucial growth area lies in ophthalmology, in which AO-assisted diagnostic systems are allowing clinicians to characterize aberrations in the human eye and in some cases to guide customized laser eye surgery. Commercial AO-based systems are also being marketed for metrology applications, while companies are actively investigating whether AO could be used for producing femtosecond laser pulses for delicate machining processes, 3-D imaging of biological samples, and boosting the range and transmission speed of free-space optical communications systems.

For these emerging opportunities to become a commercial success, the AO community must now shake off its do-it-yourself culture and focus on building low-cost, standardized components that can be exploited in a range of applications. Four key challenges must be addressed to enable that transition to happen.

From academia to industry. AO development remains largely the preserve of university research groups. But start-up firms are now launching commercial products based on AO technology, and two major initiatives—the Smart Optics Faraday Partnership (www.smartoptics.org) in England and the Center for Adaptive Optics (CfAO; cfao.ucolick.org; Santa Cruz, CA)—are working to foster relationships between industry and academia.

From do-it-yourself to plug-and-play. AO has a history of one-off developments for particular applications. AO researchers are now working with industrial partners to develop plug-and-play systems based on standard components that can readily be interchanged by nonexpert staff.

From large systems to low-cost compact packages. More work is needed to reduce the size and cost of AO systems and components. Integrated wavefront sensors in wafer-size packages and the development of more-compact wavefront modulators remain the key priorities.

From small-scale production to commercial supply. Although some AO devices are available off-the-shelf, low manufacturing volumes lead to erratic component supply, poor yields, and high prices. This situation would change dramatically if large optical companies were to introduce AO technology into their catalogs.

The biggest barrier to achieving these goals remains the low volumes of devices that are currently in demand, which is restricting investment in both product development and high-volume manufacturing processes. Conversely, demand for AO technology is unlikely to grow until there is a reliable supply of cost-effective devices.

Industry/academic initiatives such as the Smart Optics Faraday Partnership and the CfAO are attempting to break this cycle by promoting greater awareness of AO technology and funding collaborative research projects. Their efforts will be crucial in ensuring that AO makes the final leap to full commercialization.

REFERENCES

- Industrial and Medical Applications of Adaptive Optics, published by Technology Tracking, a collaboration between the Institute of Physics Publishing and QinetiQ; www.technology-tracking.com.

ALAN GREENAWAY is a professor of physics at Heriot-Watt University, Edinburgh EH14 4AS, Scotland. JAMES BURNETT is a researcher at QinetiQ, St. Andrews Road, Malvern, Worcestershire WR14 3PS, England; e-mail [email protected].