Conical refraction becomes practical

In 1832, without the benefit of experiment, Sir William Hamilton deduced the existence of an optical phenomenon called conical refraction. Later that same year, Humphrey Lloyd, a fellow at Trinity College and professor at the University of Dublin, confirmed the phenomenon. Occurring only in biaxial birefringent crystals, conical refraction causes a ray passing through a crystal surface to be refracted into a diverging cone of light.

In internal conical refraction, an entering ray diverges internally into a cone, which, upon exiting the crystal, is refracted again, becoming a hollow cylinder of rays. In external conical refraction, light focused with a well-defined cone angle onto the entrance facet becomes a single linear filament within the crystal having the diameter of the focused spot. Upon exiting, the filament diverges once again into a cone.

Now, almost two centuries later, researchers at Vision Crystal Technology (VCT; Göxe, Germany) are making practical use of the phenomenon. Why the centuries-long wait? "The answer is easy and also nearly a tragedy," says Dirk Haussmann, the company's manager. "Lloyd was able to get some biaxial material for his experiment that was naturally grown. But that is so rare that later generations had no chance to repeat what he did." The crystal used by Lloyd was aragonite, which to this day cannot be synthetically made at optical quality, according to Haussmann. Engineers at VCT have fabricated synthetic crystals of another material, monoclinic double tungstate (MDT), and demonstrated both internal and external conical refraction.

To demonstrate this effect, it is not sufficient to have a biaxial medium, notes Haussmann. The crystal must also have a pure, undisturbed molecular structure, high optical transparency, a dispersion-free optically nonactive optical axis (binormal) and biradial, parallel end facets that are (in the best case) perpendicular to the binormal and biradial, acceptable thermomechanical properties, good chemical stability, and relatively high optical refraction of all three crystallo-optical axes in which the refraction indices must have very equidistant values. To see and measure the effect clearly, the crystal should be at least 12 to 15 mm long. Only the aragonite used by Lloyd and one or two other specimens of aragonite meet all these criteria, says Haussmann.

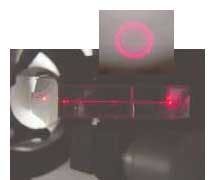

External conical refraction is best realized when the light cylinder resulting from internal conical refraction is focused into a second crystal that, in comparison to the first crystal, is rotated about 180° in the horizontal plane. Because monochromatic light with a low M2 value (good beam quality) and a small beam diameter leads to the best results, engineers at VCT used a He-Ne laser in their experiments with MDT.

Poggendorff rings

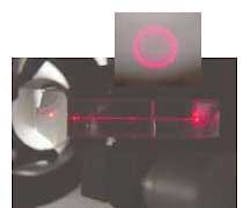

The hollow light cylinder from the internal conical refraction is, strictly speaking, two cylinders—a bright outer cylinder and a second cylinder of smaller diameter and lower intensity. The resulting rings of light at the exit facet of the crystal are called Poggendorff rings. The size of the Poggendorff rings depends linearly on the crystal length. The VCT experiment uses a 20-mm-long MDT crystal, leading to a Poggendorff ring diameter of about 0.9 mm at the exit facet. Magnification with a lens and projection onto a screen produces a clear image of the ring pattern (see figure).

To realize complete conical refraction, unpolarized or circularly polarized light is required. In the experiment, a quarter-wave plate changes the polarization of the He-Ne laser beam from linear to circular. The beam is tightly focused by a lens in front of the entrance facet of the crystal, where the beam diameter is about 200 µm. In this case, the Rayleigh length of the focused beam is larger than the crystal length itself. This is necessary because the ring pattern, caused by internal conical refraction, can only be visualized when the incoming beam is with low divergence.

In addition to being the centerpiece of optics-education kits, MDT crystals have many potential uses, says Haussmann. For example, with the help of internal conical refraction, a Gaussian beam profile could be transformed into a flat-top beam profile or into a Bessel beam. The hollow light cylinder could be used as optical tweezers with very special properties. Novel interference patterns could be generated. One promising configuration is as a depolarizer consisting of two short crystal elements fixed in a well-defined orientation to each other. This depolarizer can also be used to generate speckle-free illumination and interference patterns, of interest in holographic applications.

In the case of external conical refraction, nonlinear effects could easily be achieved, as the beam filamentation enables a constant high intensity density within the crystal and requires comparatively low input powers. For example, it would become possible to achieve stimulated Raman scattering with a continuous-wave instead of a pulsed input beam. Also, Kerr-lens modelocking with low input powers and effects based on phase conjugations may be possible.