Inexpensive, small, high-resolution liquid-crystal displays (LCDs) now seem possible with the integration of traditional CMOS fabrication methods and liquid-crystal materials. By writing miniature diffraction gratings on the chip, MicroDisplay Corp. (Berkeley, CA) can build color into its displays without adding any new steps or alignment problems to the manufacturing process.

Other tiny displays, for example, those currently being produced by companies such as Displaytech (Boulder, CO), are not easily made into intrinsically color devices—attaching color gels to several-micron-wide pixels is simply not feasible from an alignment point of view. The way around this limitation adopted by Displaytech is to illuminate the display with a sequence of red, green, and blue light-emitting-diode (LED) pulses, but this process has some disadvantages in terms of illumination flexibility and frame rate.

The new MicroDisplay technique is simple, in principle, and analogous to the way that color-embossed holograms are made. In a color rainbow hologram, masters carrying the red, green, and blue information are recorded separately and then combined on a single hologram, each recorded with a reference beam coming in at a slightly different angle. On reconstruction, each recording sends out a rainbow image that overlaps with the other two. However, because of the different recording angles, each is displaying a different part of the spectrum for any particular viewpoint. If you look at the hologram from the correct angle (usually straight on), red, green, and blue images line up to give you natural color. But if you look at the same hologram from above or below this optimal point, the colors appear to be completely wrong.

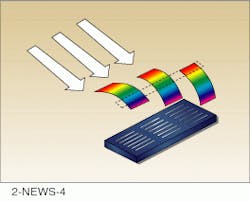

The color microdisplay developed by Philip Alvelda at the Massachussetts Institute of Technology Artificial Intelligence Laboratory works on a similar principle. Like a television set, the display consists of triads of "red," "green," and "blue" pixels. However, these subpixels are actually diffraction gratings, each with a different pitch. Changing the pitch is analogous to changing the reference angle in a hologram, and so these gratings send out spectra at different angles (see Fig. 1). By putting a stop or "window" in front of the display so that the viewer cannot look at it from the wrong angle, the LCD produces natural color from a simple white-light source (see Fig. 2).Alvelda is also trying to solve some of the other optical problems that the new technology faces. For instance, one of the applications that the displays seem most suited to is virtual-reality headsets. The microdisplays would be positioned at the corners of a pair of glasses, illuminated by light sources located in the spectacle arms. But the displays are really too small to be viewed directly, and good magnification optics (such as microscope objectives) are big, heavy, and expensive. There is no point in having an inexpensive, high-resolution screen if you can't afford the optics to view it.

Alvelda's solution was to build a computer-aided-design (CAD) tool into the CMOS design software that allows for optical predistortion of the pixel array. The equipment manufacturers specify the inexpensive optics they plan to use and calculate the aberrations that this imaging system will produce. This information is used to design the pixel array so that not only its shape is distorted, but also the size and shape of the individual pixels. Another CAD tool randomly jitters the pixel position to prevent aliasing—unwanted Moiré patterns produced by periodic structures.

According to Alvelda, MicroDisplay should have its first generation of mass-produced display chips out at the beginning of next year. Besides virtual-reality headsets, other applications may include advanced pagers, color viewers for video cameras, and wrist-wearable computers.

About the Author

Sunny Bains

Contributing Editor

Sunny Bains is a contributing editor for Laser Focus World and a technical journalist based in London, England.