Resonant-cavity LEDs operate at 3 to 5 µm

ROLAND ROUX

Resonant-cavity light-emitting diodes (RCLEDs) operating between 3 and 5 µm have been produced and tested at the Departement de Recherche Fondamentale de la Matière Condensée (Grenoble, France).1,2 Compared to conventional light-emitting diodes, RCLEDs are more efficient because they make use of microcavity and reflector technology similar to that used in vertical-cavity surface-emitting lasers (VCSELs). The RCLEDs, however, are easier to work with than VCSELs because they need only a small Bragg period number (5–6) compared to the 20–30 typically required for VCSELs. Many mid-infrared applications, including pollution detection, remote measurement, and unguided short-distance communication, would benefit from an efficient emitter in the 3–5-µm wavelength range.

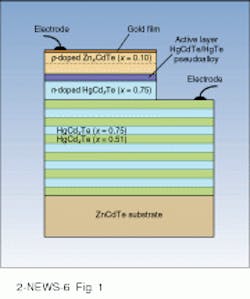

The mercury cadmium telluride (HgCdTe) alloys are convenient for use in Bragg reflectors because they provide a large index contrast—up to 20%—over a wide wavelength range (1 to 10 µm) while maintaining a quasi-constant lattice parameter. The RCLED samples were grown by molecular epitaxy on [001]-oriented ZnCdTe, with 4% Zn (see Fig. 1). The bottom mirror is a distributed Bragg reflector (DBR) comprising layers of HgCd0.51Te and HgCd0.75Te. Each layer thickness is l/4n, where n = 3.1 for Cd0.51 and n = 2.8 for Cd0.75.

The half-wavelength cavity is made from Hg0.25Cd0.75Te with a 50-nm-wide well of Hg0.49Cd0.51Te/ HgTe pseudoalloy (bandgap near 3.2 µm) at its center (antinode position). The last three periods of the bottom mirror and the first 100 nm of the cavity are doped with n-type indium. At the cavity end a 100-nm p-type layer of ZnCdTe is doped with nitrogen. The top mirror is an evaporated gold layer. The 10.5-period Bragg reflector has an 86% measured maximum reflectivity at 3.2 µm.

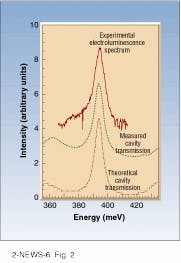

The primary benefit of the top metallic mirror arises from its reduction of the epitaxial growth duration of the microstructure, thereby avoiding the need to grow a second Bragg reflector. Moreover, because the final layer of the cavity is nitrogen-doped, the mirror serves as an ohmic contact. The device area is achieved by a 0.8 mm2 mesa. Finally, the cavity material is locally etched in order to achieve the n-doped layers of the bottom reflector and to put them electrically in contact with an indium electrode. The series resistance of the structure is only 80 W, measured at 300 K. When the device is biased at room temperature light emission is observed at the cavity resonance wavelength of 3.19 µm. (see Fig. 2).The emission wavelength obtained at 15 K is very similar to that obtained at 300 K, even though the bandgap of the quantum wells would be expected to decrease at low temperature. This indicates that the quantum-well emission is possible only in cavity mode. The emission linewidth is determined only by the cavity-resonance linewidth. The electroluminescence spectrum at 300 K measures 8 meV, representing a strong reduction of the linewidth compared to the inhomogeneous quantum-well linewidth. Thus the directivity has been improved by the microcavity, down to a 55° emission angle FWHM, and an external quantum efficiency of around 0.2 to 1.7 10-3 has been obtained.

REFERENCES

1. E. Hadji et al., Appl. Phys. Lett. 67, 18 (Oct. 30, 1995).

2. J. L. Pautrat et al., "Mercury cadmium telluride-based resonant cavity light emitting diode," to be published in J. Vac. Sci.