X-RAY OPTICS - Compound refractive lenses focus hard x-rays

X-ray microscopy has potential for nondestructive testing of opaque samples and easily damaged biological specimens. However, be cause such radiation passes through many bulk materials with little effect, the making of optics for hard x-rays—or x-rays in the kiloelectron-volt (keV) range—is difficult. Certain tricks allow optics to be built that focus hard x-rays; such optics include grazing-incidence mirrors, multiple capillaries, diffractive lenses, and mirrors with multilayer films whose individual layers are only a few atoms thick. But these optics have problems of low efficiency, poor imaging, or high complexity.

Now, researchers at the Physikalisches Institut der Rheinisch Westfälische Technische Hochschule (Aachen, Germany) and the European Synchrotron Radiation Facility (Grenoble, France) have brought imaging x-ray optics into the familiar realm of refractive optics. They have built an optical system called a compound refractive lens (CRL) that consists of a series of metal lens elements having a deep parabolic profile on each surface and rotational symmetry about the optical axis.

Each element is fabricated from polycrystalline aluminum by a pressing technique and operates in most ways like an ordinary refractive lens. The lenses are placed in alignment on two high-precision shafts, centering the elements to a common axis to a tolerance of a few microns. Because the real-or nonabsorbing-part of the refractive index is slightly less than unity for hard x-rays passing through matter, the lenses must take a concave form to permit focusing.

The small difference in refractive index between the aluminum and the surrounding air means that the effect of each element is small, which forced the researchers to place 60 or more lenses in series to create a CRL with a reasonably short focal length. But this fact also means that the requirements on lens-surface quality are not severe. In fact, the lenses are made to a surface roughness of 0.1-0.5 µm, according to Bruno Lengeler, professor at the Physikalisches Institut. "This compares very favorably with the requirements on x-ray mirrors, which need a finish of a few angstroms," he says.

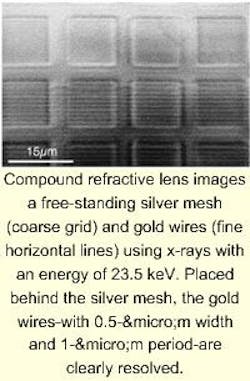

The optics have been tested at x-ray energies of 8-55 keV (corresponding to wavelengths of 0.16-0.023 nm). The resolution of the optics is limited in part by the lens aperture, which is defined by the increasing absorption of the aluminum material toward the edges of the elements. The aperture is a bit less than a millimeter, resulting in a numerical aperture of approximately 10-5. One set of optics images an area of 300-µm diameter at a magnification of 12 and a resolution of better than 0.5 µm; object-to-image distance is more than 20 m (see image above). Another set, with 100 elements, resolves to 0.34 µm. A third set images an x-ray beam-line source, withstanding the full intensity of the beam and demagnifying the source by a factor of 49 to produce a spot of very high intensity, useful for microanalysis.

Because the numerical aperture is so low, the optics have a focal depth on the order of a centimeter. For this reason, the longitudinal resolution is practically nonexistent, and the structure of a thick (1-mm) sample must be obtained by tomographic reconstruction, according to Lengeler.

The researchers aim to increase lateral resolution further by making CRLs from light elements such as beryllium or boron, materials more transparent than aluminum to hard x-rays. Lateral resolution less than 0.15 µm is possible with this approach, according to Lengeler, who notes that beryllium lenses are on the way. They should work with up to 100-keV (0.012-nm) x-rays. He adds that the researchers have already obtained images of the antennae of beetles, as well as of the calcium and potassium distribution within the root of a plant.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.