Ultralow-index fluoropolymer AR coatings improve durability of plastic optics

Pennsylvania State University (University Park, PA) researchers have developed a fluoropolymer-based, broadband antireflection (AR) coating for plastic optics with ultralow refractive index that also withstands heat and sunlight, humidity, dirt, ultraviolet (UV) light, chemicals (solvents, acids, bases), abrasion, and repeated bend (1 cm radius) and compression cycling. These are admirable attributes, considering the rigors of applications such as solar concentrators, curved aviation glass, and other environmentally challenging applications suited to plastic optics, including acrylics and polycarbonates.

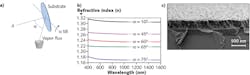

Fabricated using glancing-angle deposition (GLAD) of Teflon AF, a commercial fluoropolymer, the simple bilayer graded-index AR coatings are hydrophobic and antifogging, and exhibit a solar-spectrum-averaged (between 400 and 1600 nm) reflectance of <1% over a wide range of incidence angles. Using the GLAD process, the researchers were able to continuously vary the refractive index of the coating in the range from approximately 1.17 to 1.33 by varying the deposition angle, and found that the coatings adhere strongly to a variety of common polymer optical materials. The coatings were applied to curved lens surfaces as well as to an acrylic Fresnel lens where, for example, coating both sides increased the solar-spectrum-averaged transmittance from approximately 92% to 98%. Reference: B. Wang et al., Optica, 4, 2, 239-242 (2017).

For more info on these fluoropolymer-based antireflection coatings, please see https://coatings.specialchem.com/supplier/chemours.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.