Optics for Materials Processing: Multifocus optics target materials processing, but hint at novel uses

Whether cutting, welding, or patterning various materials using a laser, the materials-processing end result correlates directly with the size, shape, and intensity of the laser beam delivered to the workpiece. Standard optics in the laser head typically deliver a Gaussian beam with a predefined beam waist and single focal point (with wavelength dispersion, of course). However, multifocus optics—the foXXus series of objective lenses—from AdlOptica (Berlin, Germany) create multiple foci during laser beam delivery to the workpiece, increasing the effective depth of field (DOF), spreading the laser beam energy for particular machining effects, and tailoring the beam to address emerging applications, especially when the workpiece is an optically clear substrate.1

Increasing depth of field

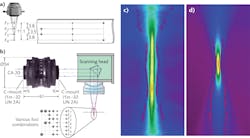

FoXXus multifocus optics are single-objective lenses or afocal systems that simultaneously create up to seven foci along the optical axis (z). Manual rotation of the optics or its optical elements adjusts the beam pattern, for example, in a four-foci lens to produce two spots close together or far apart, or four equidistant equal-intensity spots (see figure).

These multifocus optics are essentially a refractive beam-shaping system containing several optical elements with smooth polished surfaces that provide high resistance to the radiation from powerful continuous-wave (CW) or ultrafast lasers. Although available foXXus objectives have up to seven foci, the operation principle allows development of optics with several dozens of foci so that the radiation of modern lasers with constantly growing power can be efficiently distributed along the optical axis.

In their simplest implementation, multifocus optics increase the DOF of the beam delivered to the workpiece from a laser head. This can be particularly useful—especially considering that a narrow beam waist often results from conventional refractive optics with a single focal point, and is a major disadvantage to a laser-machining application if the laser head does not maintain a fixed working distance to the workpiece during operation. Not to mention that multimode lasers deliver a beam with a large beam quality (m2) or beam-parameter product (BPP), so it is often useful to maintain a certain beam size at the workpiece by expanding the DOF.

Spreading energy, shaping the beam

Whether four or seven foci, manual adjustment of the lens can produce nearly any desired spot pattern to effectively control the beamlet pattern along the optical axis independently from beam mode structure or size. Not only can this reduce the irradiance at a particular point within the workpiece substrate to reduce spatter and material ejection, but it can also produce cleaner edges when drilling or cutting materials, better transforming laser power into higher process throughput.

In the case of thick sheet-metal cutting, the elongated beam caustic produced by foXXus optics guarantees even energy delivery at the top and bottom of a workpiece for faster cutting with high edge quality. When cutting brittle materials, simultaneously producing foci at different depths inside a medium results in controlled crack propagation instead of the arbitrary cracking typical for a single-focus lens.

When using foXXus optics, standard beam-profiling equipment can be used to determine the shape of the focused beam within a particular substrate. For example, an objective with a single focus produces a high-intensity spot at the center of a material with tapering intensity above and below the main spot, whereas a four-focus lens can essentially produce an elongated and fairly consistent longitudinal beam profile useful for, say, hole drilling with minimal spatter in metal substrates.

Multifocus optics replace diffractive optical elements (DOEs) that have limited diffraction efficiency when used with multimode lasers and much lower resistance to high-power laser energies.

Addressing emerging applications

To date, AdlOptica offers numerous optical designs at a variety of wavelengths, and is also in the process of patenting the foXXus lenses specifically for cutting glass, sapphire, silicon carbide (SiC), and other brittle materials.

As you can imagine, multifocus optics with tailored focal spots inside transparent materials could lead to very interesting outcomes if applied to emerging processes such as vat photopolymerization—a form of 3D printing.

"A longstanding dream of materials-processing specialists is to have a narrow beam of a desired length independent of laser optical quality," says Alexander Laskin, marketing manager at AdlOptica. "Multifocus foXXus optics make this possible: the beam-caustic size is defined by physical properties of light, while the caustic length is defined by the optics design. This unique property is a key to improving laser efficacy in sheet-metal cutting, but also for welding and expanding applications in laser microprocessing of brittle materials like sapphire in LED manufacture or glass cutting and drilling for various display techniques."

REFERENCE

1. See https://goo.gl/eEieWY and http://adloptica.com/foxxus.htm.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.