Optical scanners intended to modulate or deflect light are often galvanometer-based mechanical systems. At high materials-processing speeds, demands on the bearings for moving parts are exceptionally high, and cross-axes wobble (the vertical deviation of a scanned laser beam from its nominal linear axis) is typically on the order of 200 μrad. But a new silicon-based resonant microelectromechanical systems (MEMS) scanner from the Fraunhofer Institute for Photonic Microsystems (IPMS; Dresden, Germany) has demonstrated cross-axes wobble less than 35 μrad; the scanner oscillates at 23 kHz with a mechanical amplitude of ±9°.

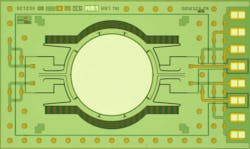

A typical Fraunhofer MEMS scanner chip (4.0 × 2.6 mm2) deflects a beam using an aluminum-coated (reflectivity greater than 86% between 450 to 650 nm), 1.2-mm-diameter, circular silicon MEMS mirror. With average power consumption lower than 300 µW, the scanner operates at laser powers up to 600 mW at 670 nm. Unlike galvanometer-based scanners, the design uses photolithographic methods to enable high symmetry and reduce unbalanced masses. And, compared to other MEMS designs, the actuation—based on interdigitated-comb structures—creates a very energy-efficient driving mechanism and minimizes process-related accidental asymmetry. More than 150 MEMS scanner designs can be accessed online using the Fraunhofer IPMS Scanner-Configurator. The customer simply inputs the desired scan frequency, maximum mechanical amplitude, mirror diameter, and maximum mechanical deformation that can be tolerated.

Contact André Dreyhaupt at [email protected].

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.