Lasers replace conventional technology in display designs

Lasers replace conventional technology in display designs

Laser-based displays designed with the proper primary wavelengths allow large color gamuts with fixed color temperatures.

David Hargis and Allen Earman

Recent advances in compact, air-cooled, diode-pumped, solid-state visible microlasers have enabled the development of portable laser displays. Lasers are being developed for both "back-lit" displays and "direct-write" displays. In back-lit displays, the lasers replace arc lamps in liquid-crystal displays (LCDs) or digital-micromirror-display (DMD) projectors. In direct-write displays, the image is formed by directly modulating and scanning the laser beam.1 Compact, multiwatt red-green-blue (RGB) output laser modules have been demonstrated for use as "light engines" in projection displays generating greater than 500 ANSI lumens (see photo).

In another article, we discussed the development of microlasers (see Laser Focus World, May 1998, p. 243). This article focuses on the use of microlasers in back-lit-display applications. We also touch briefly on direct-write-display applications.

Microlaser advantages

The main advantages of microlaser-based displays are long lifetime (with low maintenance), large color gamut, color accuracy, image uniformity, high resolution, and large depth of focus. These advantages make them attractive for near-term display applications, such as simulators, command and control centers, video walls, and high-end computer-aided-design workstation monitors, and for long-term applications such as electronic cinema.

Lifetimes of both cathode-ray-tube (CRT) projectors and arc-lamp-based projectors are limited to between a few hundred and a few thousand hours, which leads to significant maintenance costs in high-use applications. The expected lifetimes of the microlasers are approximately 15,000-20,000 hours, limited only by the lifetime of the pump diode lasers, which have lifetimes that are increasing dramatically with ongoing improvements in the technology. This lifetime will significantly reduce projector maintenance costs associated with arc-lamp replacement and CRTs.

Arc lamps emit over a broad spectrum, making them inefficient in producing the narrow bands of red, green, and blue light that are required for a full-color display. Although some effort has been directed toward tailoring the spectra of arc lamps, this fundamental inefficiency remains. Meanwhile, the wider the spectral pass band, the less saturated the colors are and the smaller the color gamut. If filters are used to isolate the desired wavelengths, a significant fraction of the light is absorbed (or reflected), and efficiency is impaired. The ultraviolet and infrared filters required to reject undesirable radiation also reduce the visible light available. In addition, as an arc lamp degrades, its color temperature shifts causing a change in the apparent colors of the images.

Primary wavelengths

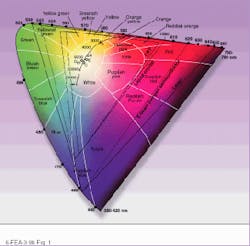

Laser-based displays designed with the proper primary wavelengths give rise to a very large color gamut with a fixed color temperature. Laser Power Corp. (LPC; San Diego, CA) has developed polarized microlasers with outputs at wavelengths of 457, 532, and 656 nm. These wavelengths yield an exceedingly large color gamut, thereby providing a display technology that nearly encompasses the entire color range of the human visual system. Color gamuts consistent with different technologies are shown in Fig. 1. A microlaser-based display provides greater color saturation in all three primaries than that afforded by conventional technologies. Due to the inherent monochromatic nature of laser light, color filters are not required. In addition, the primary wavelengths do not shift with time, so, as long as the relative RGB amplitudes from each laser are maintained, the color temperature remains fixed.

Another problem associated with the use of arc lamps stems from the diffi culty in efficiently coupling their broad angular, unpolarized output onto small spatial light modulators (SLMs) that have finite angular acceptance (such as DMDs and LCDs). As the power of an arc lamp increases, the arc gap length also increases, making the coupling task ever more difficult. Hence, as SLMs become smaller and as resolution increases, it becomes more difficult to attain good contrast and good illumination efficiency with arc lamps. Lasers, due to their inherent high brightness, overcome this problem. In addition, the high spatial coherence of lasers means a very large depth of focus can be achieved with excellent image uniformity. The output linear polarization of microlasers also eliminates the requirement for the complicated optical schemes to split and recombine light from an arc lamp for illumination of polarization-sensitive SLMs.

Wavelength and power

The specific laser requirements for display applications are strongly dependent on the type of architecture used. Requirements differ for back-lit and direct-write displays. In general, to appeal to a larger marketplace than has been addressed to date (more than 100,000 lasers per year), the lasers must achieve reliable, efficient, watt-class performance (more than 10,000-hour lifetime). The laser head size must also be less than 10 cubic inches, and the cost must be in the range of a few hundred dollars.

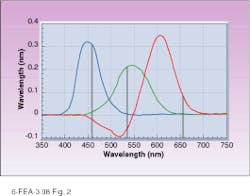

A study performed on the spectral response of the human eye relative to multiple-color display systems concluded that the wavelengths for optimum luminous efficiency for the three primaries of a display are 610 nm--red, 530 nm--green, and 450 nm--blue (see Fig. 2).2 This combination maximizes the visual response per watt of input light power. Hence, a system based on these primaries requires the minimum optical power to generate a specified brightness. Fortuitously, LPC has developed efficient microlaser sources that are very close to two of these wavelengths--457 nm in the blue and 532 nm in the green. Most of the development work in the red has focused on microlasers emitting at 656 nm and red-emitting aluminum gallium indium phosphide (AlGaInP) diode lasers at about 650 nm, both of which require significantly more power than the green and blue to produce a D65 (blackbody at 6500 K) white.

The ideal red wavelength, which optimizes color gamut and required optical power, is at approximately 625-635 nm. Although the color gamut is reduced slightly, the eye is much more responsive at this wavelength, and the power level required for a brightness equivalent to a 656-nm source is reduced by a factor of about four.

For a 500-lumen D65 white image, the optical power requirements are 0.45 W at 457 nm, 0.62 W at 532 nm, and 2.1 W at 656 nm or 1.62 W at 650 nm. At 630 nm, the red power requirement drops to 0.5 W. These power levels are required on the screen, so the actual power levels that must be produced by the laser are a function of the optical efficiency of the projector. A back-lit projector with an optical efficiency of 33%, for example, requires laser power levels of 1.35 W at 457 nm, 1.87 W at 532 nm, and 4.87 W at 650 nm. Comparable efficiencies are achieved with direct-write projectors.

Beam quality and amplitude noise

The beam-quality and amplitude-noise requirements are strictly dependent on the technique that is used to generate the image. The requirements are generally simple to achieve for back-lit displays and more demanding for direct-write displays. In both cases, the beam-quality specification can be defined in terms of the product of the laser-beam size and the divergence angle. Typically, for laser beams that exhibit Gaussian distributions, this is defined as the product of the beam-waist radius and the half-angle beam divergence. The peak-to-peak amplitude noise of the laser output power is measured in terms of the fractional percentage of the dc value.

For back-lit displays, the required beam quality is a function of the optical illumination system and of the aperture size and angular acceptance of the SLM. The requirements can, therefore, vary tremendously, depending upon the specific SLM used. For example, a system using a reflective LCD, which has a polarizing beamsplitter cube as the polarizer/analyzer, has a finite acceptance angle dictated more by the cube coating characteristics than by the LCD panel. In addition, some speckle-elimination and beam-shaping techniques have different spatial and angular acceptance criteria to achieve speckle-free and uniform images.

For a typical back-lit LCD projector, the input of the optical system requires a beam waist of 2.5 mm coupled with a maximum half angle of 5°. This corresponds to a beam product of about 220 mm-mrad. For a laser operating at 532 nm, this requires an M2 of nearly 1300. Thus, a laser can be operating 1300 times diffraction limited and still be acceptable.

Back-lit displays are fairly forgiving with regard to amplitude fluctuations on the laser illumination. Because the vast majority of SLMs are updated at 60 Hz, fluctuations at higher frequencies are essentially time integrated by the viewer`s eye and are not apparent in the image. Of course, if the laser is flickering at 10 Hz there is an obvious artifact, and there are some subtle "beating" effects if there are large amplitude noise spikes up to about 300 Hz. No image artifacts are apparent if the amplitude noise is kept below 3% peak-to-peak from dc to 300 Hz.

Direct-write displays

In a direct-write laser display, the laser beam ultimately forms the individual pixels of the image. Thus, in high-resolution systems the number of pixels within a given scan angle is limited by how near the laser beam is to diffraction limited. In addition, in large-screen projection applications a laser beam with a homogeneous distribution is desirable to avoid oddly shaped pixels. Thus, good beam quality is important for these types of laser displays.

The laser beam usually is scannned by a polygon mirror to generate the horizontal lines, and a galvanometric scanner provides the vertical scan. The laser beam is collimated through these scans and then focused by a lens to form an image. The beam quality of the laser beam limits the level of collimation achievable in the scanning region and, therefore, the minimum scan angle that is resolvable. For a 5120 ¥ 4096 display, the beam product requirement is 1.6 mm-mrad. For a green-output laser operating at 532 nm, this corresponds to an M2 of about 9.

Due to the spatial/temporal relationship of the scanned laser beam in direct-write displays, high frequency-amplitude noise is an important issue. If the laser amplitude is fluctuating at frequencies that are less than, or on the order of, the video modulation bandwidth, artifacts or noise will be apparent in the image. The perception of the noise will be a function of the noise amplitude and frequency spectrum and of the type of video image displayed. It has been found experimentally that a 3% peak-to-peak noise is acceptable at frequencies less than the maximum pixel-writing rate. Amplitude fluctuations at frequencies greater than the pixel-writing rate are not readily apparent in the image. A nominal pixel-writing rate for a direct-write display is 50 MHz.

The beam quality requirements for back-lit and direct-write displays are approximately 220 mm-mrad and 1.5 mm-mrad, respectively. The amplitude-noise requirements are less than 3% peak-to-peak noise for frequency regimes from dc to 300 Hz for back-lit displays and dc to 50 MHz for direct-write displays. Thus, the beam-quality and noise requirements are significantly relaxed for back-lit projectors. o

ACKNOWLEDGMENTS

The authors and Laser Power Corporation wish to thank Proxima Corp., Laser Display Technologie GmbH, and CAE Electronics for their support. Additional support was provided by contracts from the NIST Advanced Technology Program, Air Force Armstrong Laboratories, and DARPA. Coauthors to this article, in addition to the two listed above, include Robert Bergstedt, Paul Gullicksen, Randy Hurtado, Art Minich, Sven Nelte, David Ornelas, Maurice Pessot, Eric Takeuchi, Bill Vivian, and Joseph Zarrabi, all from Laser Power Corp.

REFERENCES

1. R. Bergstedt et al., SPIE Proc. Cockpit Displays IV: Flatpanel Displays for Defense Applications, Orlando, FL, Darrel Hopper, ed., 362 (1997).

2. W. Thornton, "Matching lights, visual response, and the painfully sub-human CIE Standard Observers," Perceiving, Measuring and Using Color 1250, 26 (1990).

A previous article on laser displays appeared

in the May issue.

Red (656 nm), green (532 nm), and blue (457 nm) microlasers are now available for display applications

FIGURE 1. Microlaser-based display provides greater color saturation in all three primaries than that afforded by conventional technologies. The color becomes more "pure" or saturated in the areas close to the edges of the diagram.

FIGURE 2. Projection system based on the primary wavelengths of 610 nm (red), 530 nm (green), and 450 nm (blue) requires the overall minimum optical power to generate a specified brightness. Microlaser sources are currently available near two of the primary wavelengths--457 nm in the blue and 532 nm in the green.

DAVID HARGIS is vice president of microlaser technology, research division, and ALLEN EARMAN is product manager in the microlasers division of Laser Power Corp., 12777 High Bluff Dr., San Diego, CA 92130.