Stretchable metasurface lens changes in focal length from 600 to 1400 μm

A dielectric metasurface, which is a pattern of subwavelength-sized and spaced nanoscatterers that each can locally modify phase and/or polarization of the light, can, if properly designed and patterned, imitate the function of a bulk optical device—for example, a lens. Advantages of a dielectric metasurface lens include extreme thinness and lightness; now, an easily adjustable focus can be added to these advantages. Researchers at the California Institute of technology (Caltech; Pasadena, CA) have created a dielectric metasurface lens that, when stretched, changes focus. While stretchable (and thus tunable in some way) metasurfaces have been created before, the Caltech lens is efficient, robust, low in aberrations because of its aspherical design, and has a very large focal range.

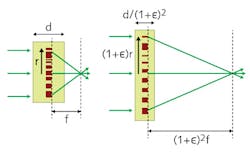

The metasurface nanopost scatterers themselves are of amorphous silicon (a-Si), while the stretchable substrate and encapsulant is of polydimethylsiloxane (PDMS), which is commonly known as silicone. The 690-nm-tall nanoposts vary in width and spacing across the lens, allowing for modification over the entire 0 to 2π phase range. The 100-μm-thick, 200-μm-diameter lens is mounted between two Teflon rings. To radially stretch the lens to change its focal length, a Teflon tube is pushed against the metasurface. Tested at a wavelength of 915 nm, the lens had a focal-length range from 600 to 1400 μm and maintained a diffraction-limited focus. After stretching and unstretching 10 times, the optical-intensity profile at focus remained the same. Reference: S. M. Kamali et al., arXiv:1604.03597v1 (Apr. 12, 2016).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.