Fluid Lenses: Electrowetting variable-focus optics span visible to mid-IR

A type of electrically focusable, no-moving-parts type of lens (and a steering prism as well) developed by researchers at the University of Colorado (Boulder, CO) has a spectral band of 400 to 5000 nm and has been experimentally demonstrated at wavelengths of 588, 1550, and 3000 nm. The lenses are based on electrowetting, where varying a voltage changes the wettability and thus the contact angle of a fluid lens, also changing its shape. While the electrowetting concept itself isn't new, the wide spectral range is. Uses include adaptive optics for imaging, spectroscopy, microscopy, lidar, and persistent surveillance.

Synthesized fluid

The lens contains two fluids with differing refractive indices. The fluids are a room-temperature ionic liquid (RTIL) called N-Propyl-N-methylpyrrolidinium Bis(fluorosulfonyl)imide (Pyr133a), and dodecane.

An RTIL is a synthesized fluid consisting of a large organic cation paired with an inorganic anion. In the midwave-infrared (MWIR) region, a typical RTIL has a cation with a relatively narrow absorption band between 3333 and 3520 nm because of a bond resonance; other than that band, RTILs can be synthesized that have the rest of the MWIR free of bond-resonance absorption bands. RTILs have good wettability, IR transparency, good conductivity, a low vapor pressure (which reduces evaporation), and other features that are appropriate for electrowetting applications. Previously, RTIL-based electrowetting lenses had been demonstrated only in the near-IR at 1000 nm.

To make an electrowetting lens, the researchers start with a glass tube, coating the inside of it with thin-film electrodes, a thin-film dielectric, and a hydrophobic coating to increase the contact angle. The tube is then bonded at one end to a substrate that transmits light in the spectral region of interest.

Three devices were made: A prism for use in the visible-2000 nm region with an inner tube diameter of 6 mm, a height of 10 mm, two separate electrodes on the inner sidewall to enable tilting the fluid/fluid prism surface, and a glass substrate; a lens for visible-2000 nm applications with a glass tube having an inner diameter of 2.7 mm and a glass substrate; and a lens for MWIR applications with size similar to the first lens, but with a silicon substrate.

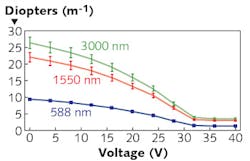

A periodically poled lithium niobate (PPLN) optical parametric oscillator (OPO) pumped with a Q-switched Nd:YAG laser, along with filters (to isolate the 3 μm idler or the 1.5 μm signal), provided the near-IR and MWIR light for testing. A scanning knife edge, along with measurements of beam width and divergence angle, were used to determine the lenses' focal properties, which were about 7, 19, and 23 diopters at 588, 1550, and 3000 nm, respectively, at a 15 V DC applied voltage (see figure for full voltage-dependent focal ranges). The radius of curvature of the fluid/fluid interface change from 1.68 to 12.5 mm over the voltage-tuning range.

The electrowetting steering prism, which was tested at 1550 nm using a laser-diode source, steered the laser beam over a 1.12° angle (a range can easily be amplified with additional conventional optics, or by using a different nonpolar liquid in place of dodecane to increase refractive-index contrast).

The researchers note that, to fabricate a single device that can function through the visible and MWIR, the device's glass tube could be bonded to a substrate made from a wideband material such as calcite or sapphire.

REFERENCE

1. A. M. Watson et al., arXiv:1603.00421v1 (Mar. 1, 2016).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.