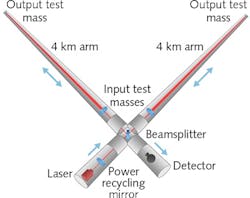

The recently celebrated detection of gravitational waves by the Laser Interferometer Gravitational-Wave Observatory (LIGO) is indeed incredible, considering that LIGO's interferometer optics only absorb one photon out of every 3.3 million, with the rest being reflected or transmitted. Recognizing that even this tiny amount of absorption causes heat distortion and spatial changes to the mirrors that critically affects LIGO's ability to make the precise measurements needed, the LIGO team worked with 10-year collaborator Access Laser (Everett, WA) to develop a method that provides real-time correction for distortion in the optics of its interferometer.

Using ultrahigh-stability carbon-dioxide (CO2) lasers from Access, a process was developed to heat the LIGO mirrors in a manner precise enough to counteract the shape changes that occur as a result of optical heating from LIGO's main laser. Since the typical CO2 laser beam has a Gaussian shape, the optical correction system was designed with an annular-shaped heating profile to provide correction specifically where the main LIGO beam was not present. In the newest generation, real-time feedback is provided to the Access CO2 laser using a line-tracker module that keeps the laser locked on a single wavelength.

By eliminating the CO2 laser noise that comes from line hop, nonuniform discharge, and spurious longitudinal and transverse modes, the subsequent noise floor and temperature-based optical distortion of the LIGO interferometer are driven down to a level that allows the almost vanishingly small gravitational waves to be measured. Reference: https://dcc.ligo.org/public/0027/T050064/000/T050064-00.pdf.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.